Attention

Attention

Servo drives including the Safety module shall be used only in Pollution Degree environments class

Servo drives including the Safety module shall be used only in Pollution Degree environments class

PD1 or PD2 according to IEC 61800-5-1: During normal operation only non-conductive pollution

PD1 or PD2 according to IEC 61800-5-1: During normal operation only non-conductive pollution

may occur, temporarily occurring conductivity caused by condensation may only be expected

may occur, temporarily occurring conductivity caused by condensation may only be expected

when the servo drive is out of operation.

when the servo drive is out of operation.

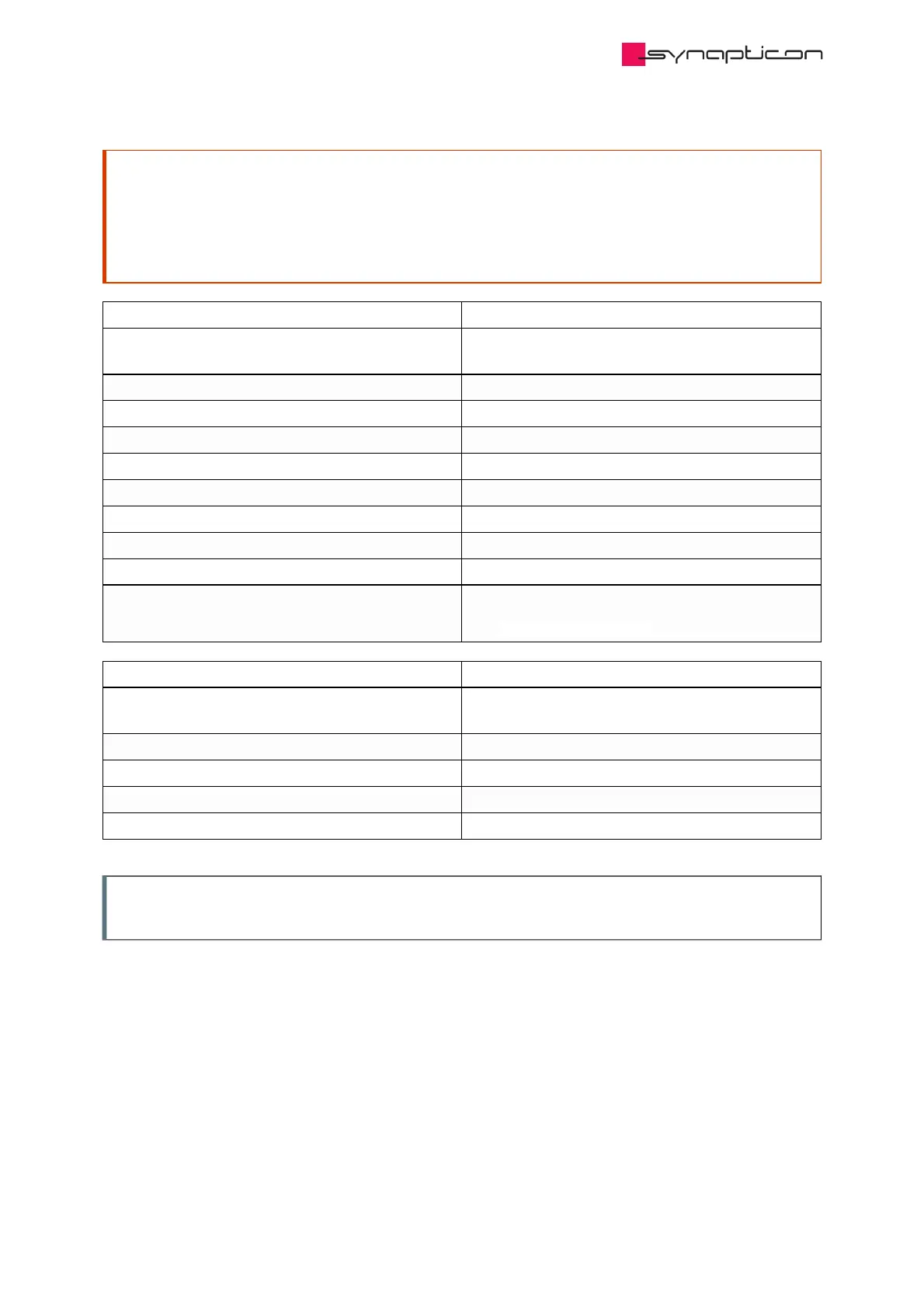

Safe digital inputs (STO-SBC input)

Number of digital inputs 2 (dual-channel safety input for activating STO-

SBC function)

Digital input type according to IEC61131-2:2007 Type 1

Voltage range 0-60 VDC

Max. transient input voltage 80 VDC

Input voltage, logic 1 15-60 V

Input voltage, logic 0 0-5 V

Input current Max. 6 mA (@24 VDC)

Test pulse toleration (OSSD pulses) Max. 1 ms

Reverse voltage protected Yes

Allowed discrepancy between digital inputs 100 ms

See safety diagnostic section

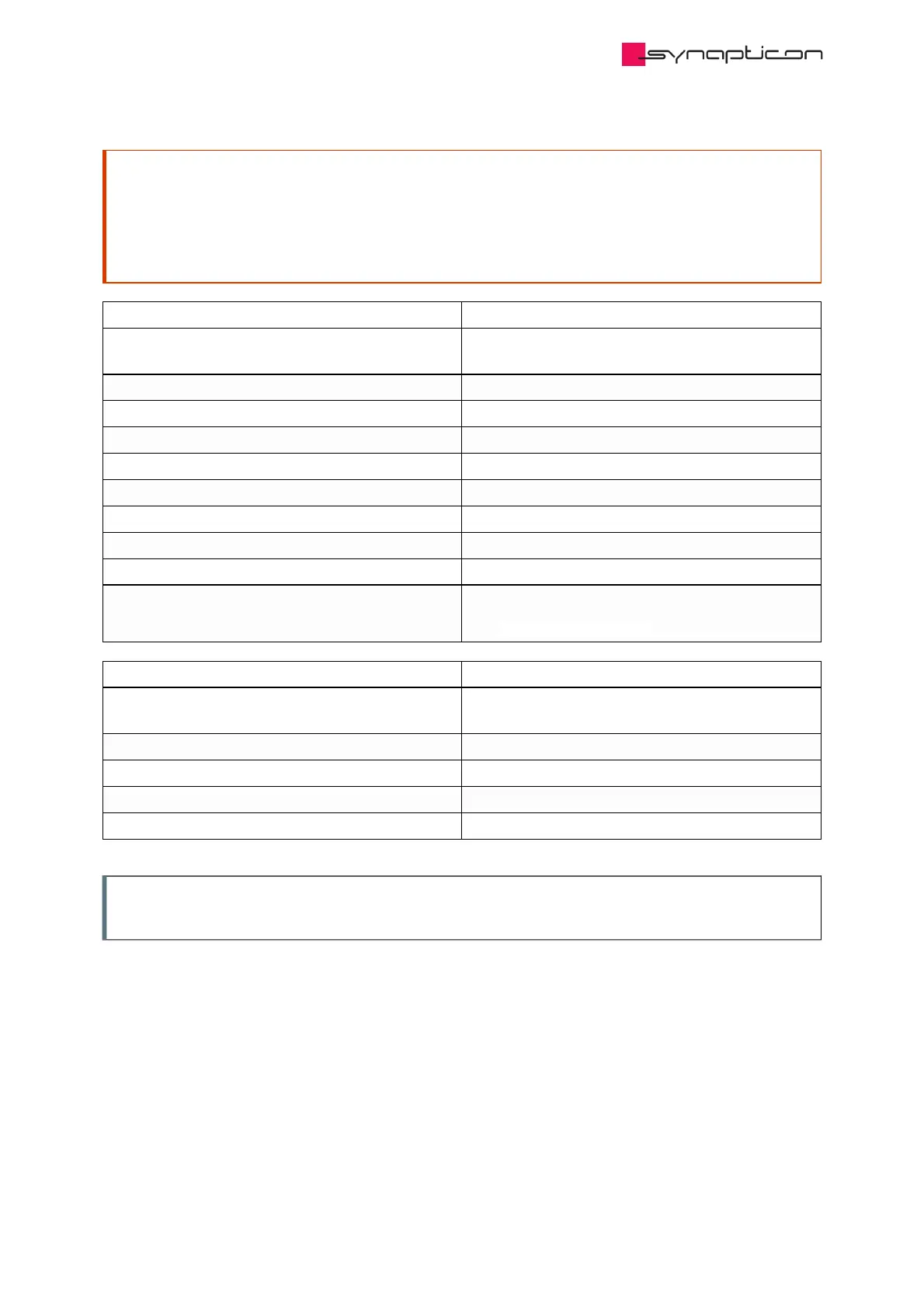

Safe brake output (SBC)

Number of digital outputs 2 (dual-channel safety output for one brake

system)

Max. output voltage Servo drive main power supply (48 VDC)

Min. output voltage 0 V

Max. current. 1 A

Max. peak current. 4 A

Note

Note

This PWM controlled brake is configured by

This PWM controlled brake is configured by

the same object

the same object

as the regular brake.

as the regular brake.

Loading...

Loading...