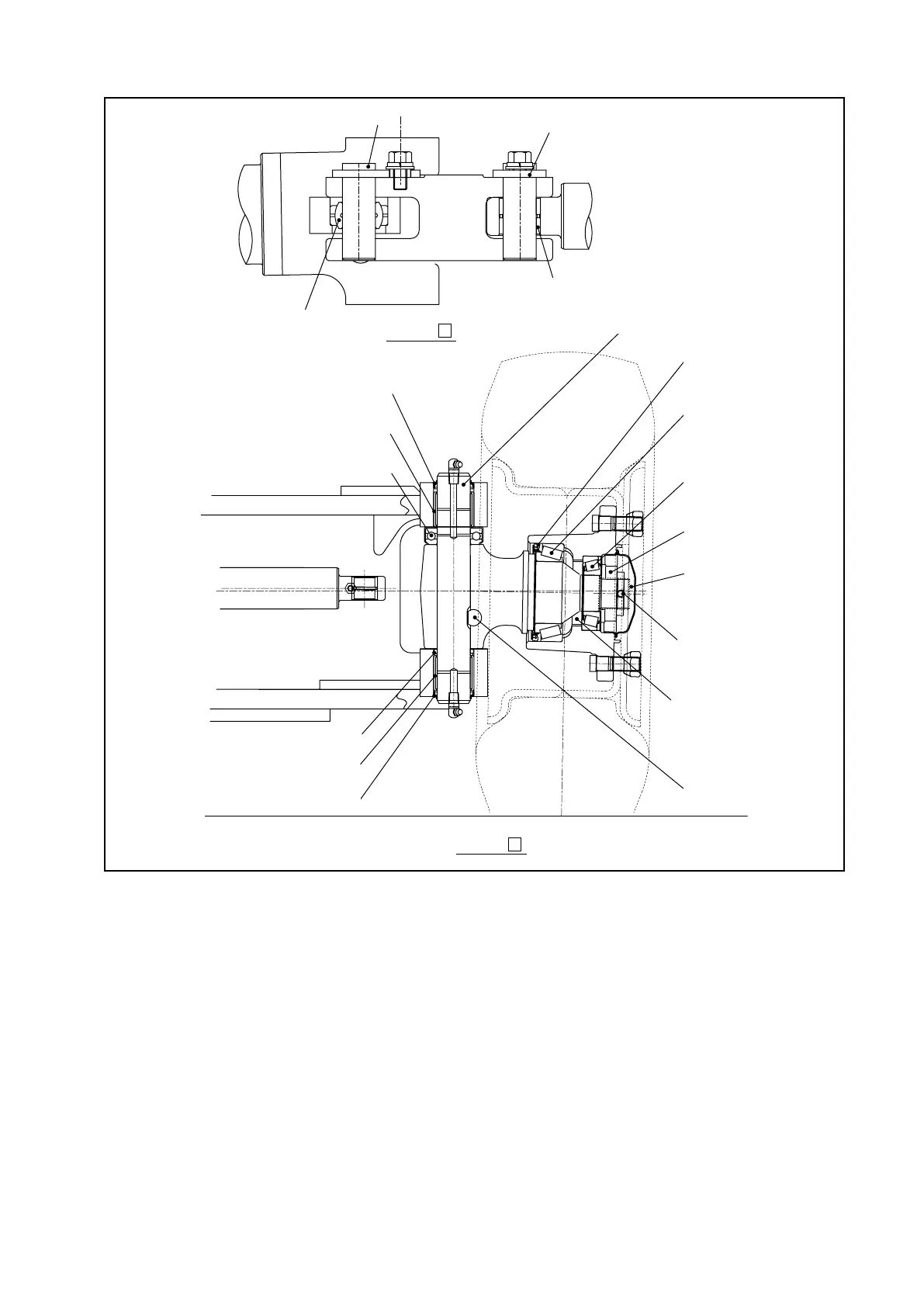

(1) Knuckle and king pin

The knuckle is supported with a king pin which in turn is secured at the knuckle side with a lock

pin. The top and bottom of the king pin are tted to the axle boss with needle bearings.

Between the axle boss and the knuckle is a thrust bearing to let the knuckle smoothly rotate

around the king pin, sustaining load.

The top and bottom needle bearings and thrust bearing are lubricated by grease supplied through

the grease ttings at top and bottom of the king pin.

(2) Wheel hub

The wheel hub is mounted on the knuckle spindle with two tapered roller bearings and its

preload is adjusted with a nut.

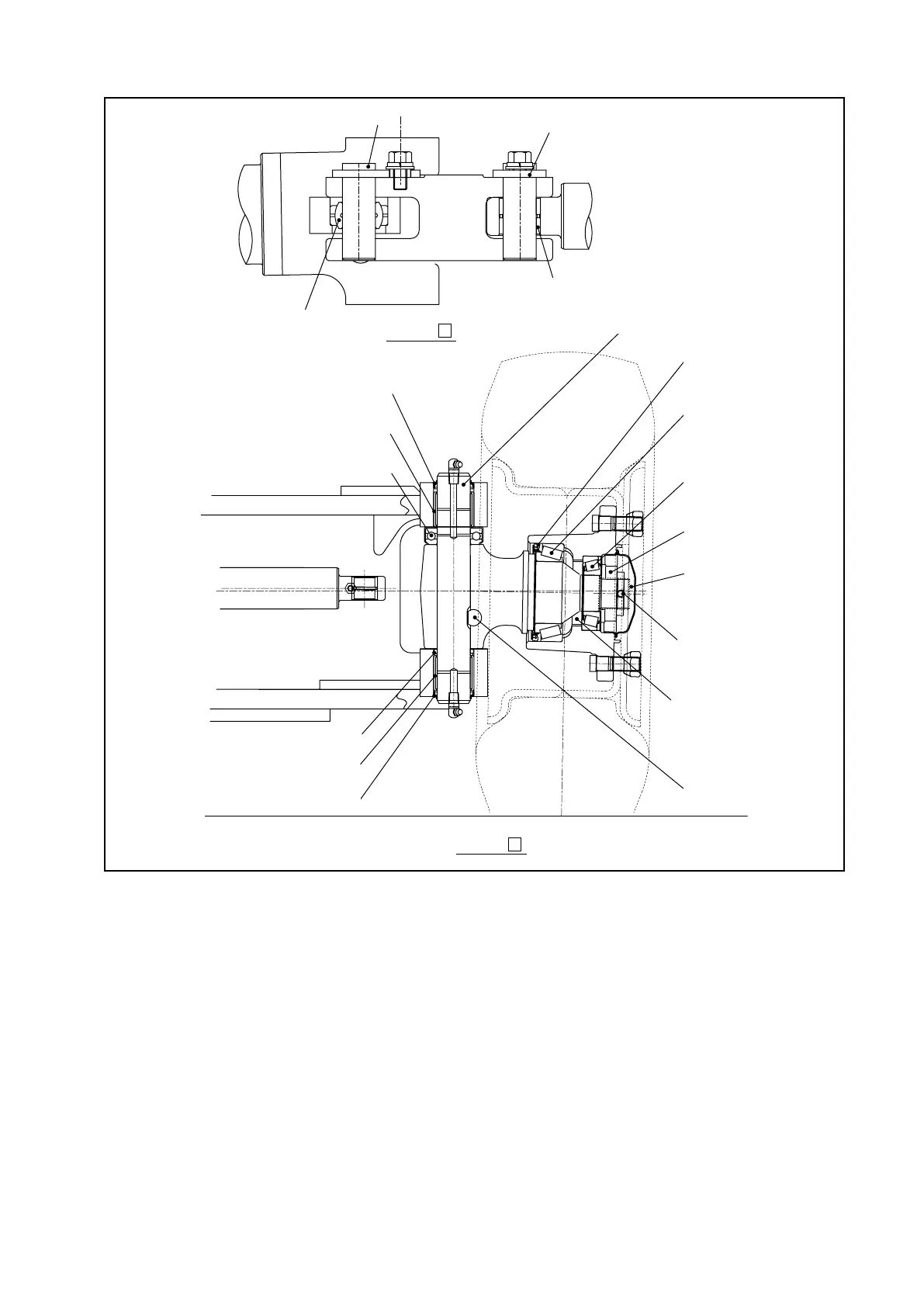

Fig. 6A.4 Steering Axle (for 2.0- to 3.5-ton Trucks) 2/2

Detail of

D

PIN

PIN

SPHERICAL

BUSHING

BUSHING

OIL SEAL

NEEDLE BEARING

THRUST BEARING

“O”-RING

NEEDLE BEARING

OIL SEAL

KING PIN

OIL SEAL

TAPERED ROLLER

BEARING

TAPERED ROLLER

BEARING

ADJUSTMENT NUT

COTTER PIN

CAP

Fill 50% of the space

with grease

LOCK PIN

Detail of

C

6A. STEERING SYSTEM (ORBITROL type)

Loading...

Loading...