CC1101

SWRS061H Page 27 of 98

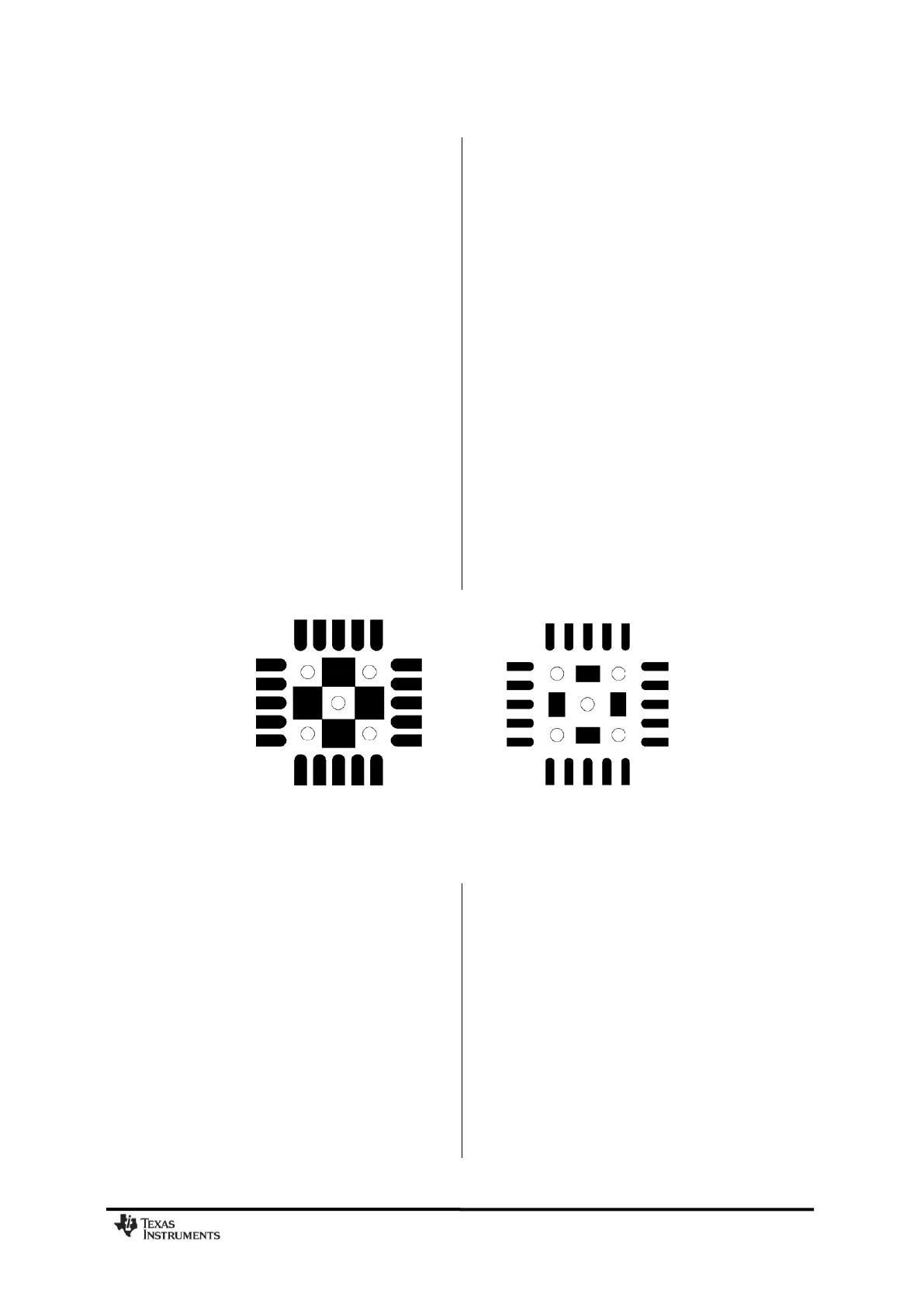

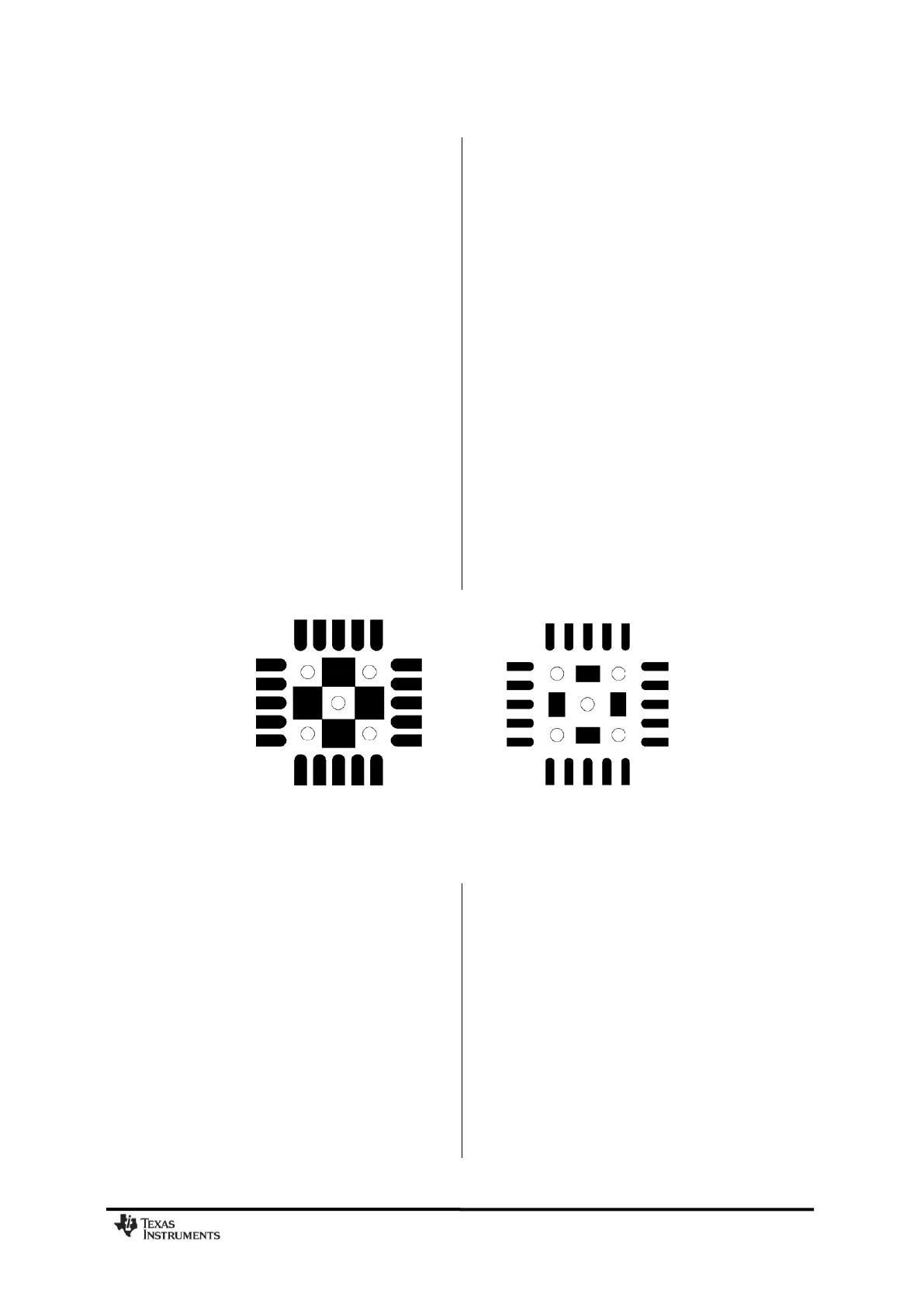

reflow process, which may cause defects

(splattering, solder balling). Using “tented” vias

reduces the solder paste coverage below

100%. See Figure 12 for top solder resist and

top paste masks.

Each decoupling capacitor should be placed

as close as possible to the supply pin it is

supposed to decouple. Each decoupling

capacitor should be connected to the power

line (or power plane) by separate vias. The

best routing is from the power line (or power

plane) to the decoupling capacitor and then to

the

CC1101

supply pin. Supply power filtering is

very important.

Each decoupling capacitor ground pad should

be connected to the ground plane by separate

vias. Direct connections between neighboring

power pins will increase noise coupling and

should be avoided unless absolutely

necessary. Routing in the ground plane

underneath the chip or the balun/RF matching

circuit, or between the chip‟s ground vias and

the decoupling capacitor‟s ground vias should

be avoided. This improves the grounding and

ensures the shortest possible current return

path.

Avoid routing digital signals with sharp edges

close to XOSC_Q1 PCB track or underneath

the crystal Q1 pad as this may shift the crystal

dc operating point and result in duty cycle

variation.

The external components should ideally be as

small as possible (0402 is recommended) and

surface mount devices are highly

recommended. Please note that components

with different sizes than those specified may

have differing characteristics.

Precaution should be used when placing the

microcontroller in order to avoid noise

interfering with the RF circuitry.

A CC1101DK Development Kit with a fully

assembled CC1101EM Evaluation Module is

available. It is strongly advised that this

reference layout is followed very closely in

order to get the best performance. The

schematic, BOM and layout Gerber files are all

available from the TI website ([1] and [2]).

Figure 12: Left: Top Solder Resist Mask (Negative). Right: Top Paste Mask. Circles are Vias

8 Configuration Overview

CC1101

can be configured to achieve optimum

performance for many different applications.

Configuration is done using the SPI interface.

See Section 10 below for more description of

the SPI interface. The following key

parameters can be programmed:

Power-down / power up mode

Crystal oscillator power-up / power-down

Receive / transmit mode

RF channel selection

Data rate

Modulation format

RX channel filter bandwidth

RF output power

Data buffering with separate 64-byte

receive and transmit FIFOs

Packet radio hardware support

Forward Error Correction (FEC) with

interleaving

Data whitening

Wake-On-Radio (WOR)

Details of each configuration register can be

found in Section 29, starting on page 66.

Figure 13 shows a simplified state diagram

that explains the main

CC1101

states together

with typical usage and current consumption.

For detailed information on controlling the

Loading...

Loading...