INTRODUCTION & DESCRIPTION 10 Manual 0-2568

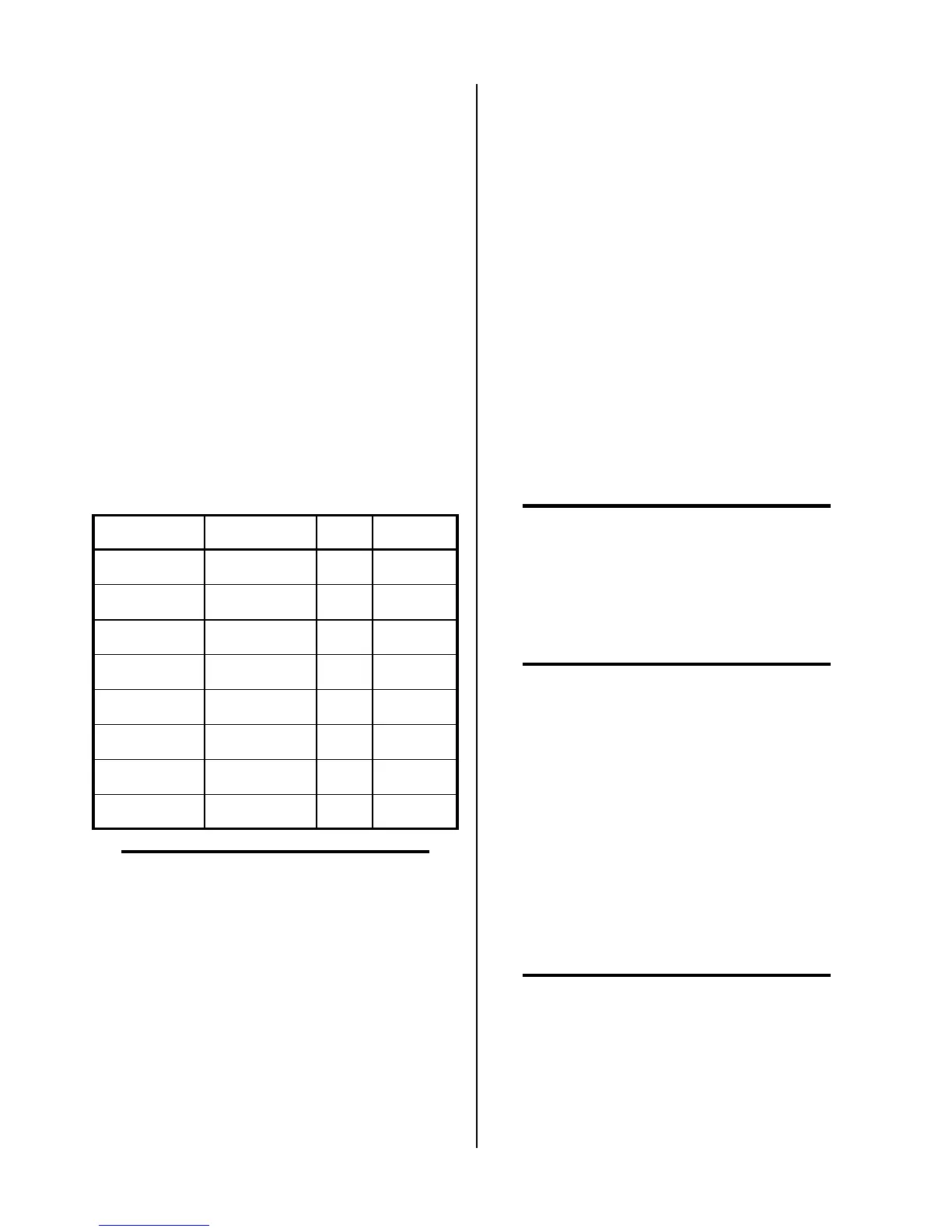

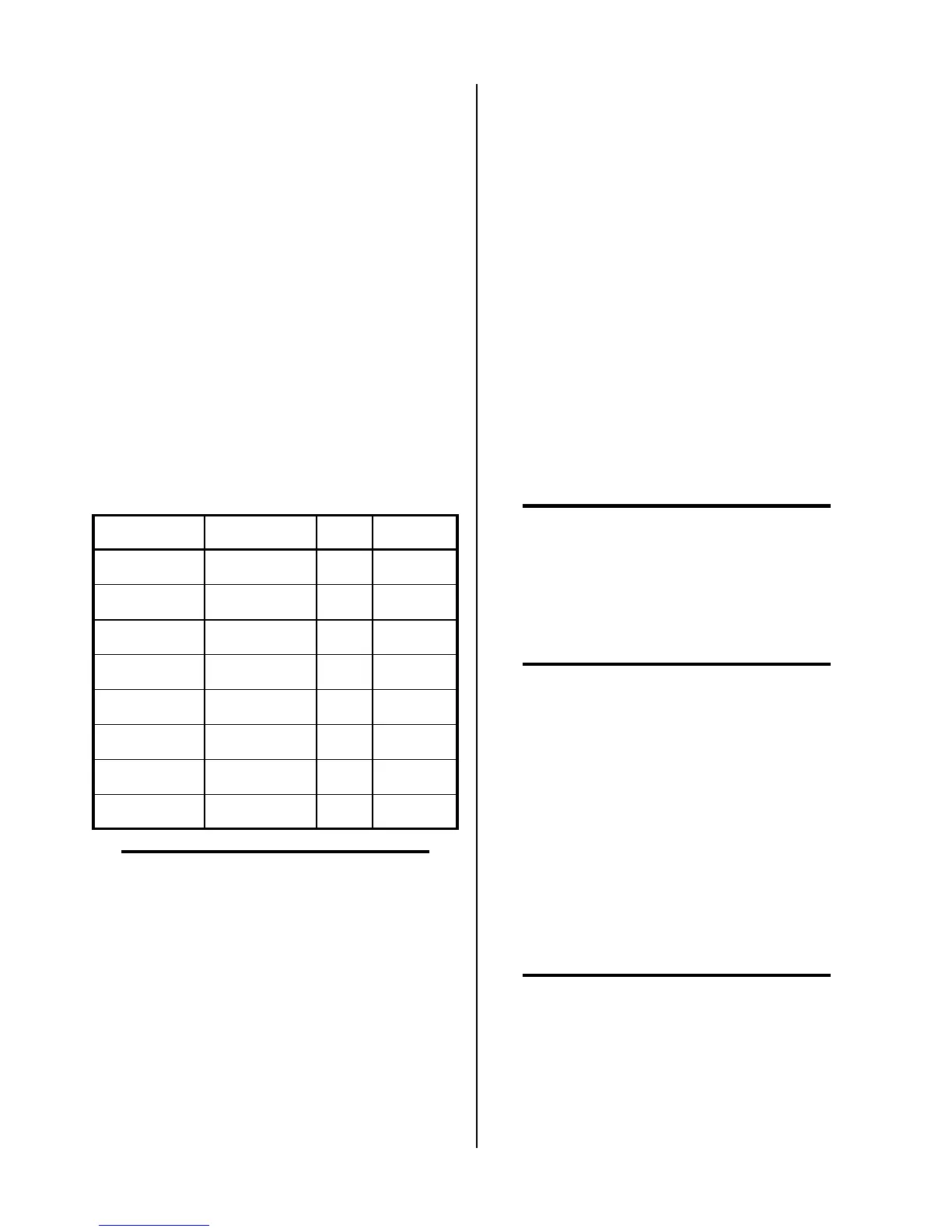

2.03 Specifications & Design

Features

The following apply to the Master Power Supply only:

1. Controls

ON/OFF Switch, Output Current Control, RUN/

SET/PURGE Switch, Secondary Gas Regulator,

Plasma Gas Regulator, Secondary Mode Switch, Sec-

ondary Water Flowmeter/Regulator, Optional Arc

Hour/Counter Meters

2. Control Indicators

LED Indicators:

AC , TEMP, GAS, DC, PILOT, COOLANT PRES, and

COOLANT COND

Gauges:

Secondary, Plasma, and Coolant Pressure Gauges

3. Input Power

Voltage Frequency Phase Amperage

200 50 or 60 Hz 3 98

220 50 or 60 Hz 3 89

230 50 or 60 Hz 3 85

380 50 or 60 Hz 3 51

415 50 or 60 Hz 3 47

460 50 or 60 Hz 3 42

500 50 or 60 Hz 3 40

575 50 or 60 Hz 3 34

NOTE

Refer to Appendix I for recommended input wir-

ing size, current ratings, and circuit protection re-

quirements.

Amps depends on input voltage (Refer to Appendix

I).

4. Output Power

Master Power Supply:

Continuously adjustable by potentiometer from 50

to 150 amps

With Slave Power Supply:

Continuously adjustable by potentiometer from

100 to 300 amps

5. Duty Cycle

100%

6. Pilot Modes

Auto-Restart, Pre-Flow Delay, "Recycle Required"

7. CNC Signals

Enable, Start/Stop, OK-To-Move, Pilot Sensing Relay

(PSR), Full CNC Available with Remote

8. Coolant Pressure

Internal Service-adjustable

130 psi (8.8 BAR) at zero flow

120 - 125 psi (8.2 - 8.5 BAR) at 0.6 gpm (2.6 lpm)

9. Coolant Flow Rate

0.5 gpm (2.2 lpm) with 150 feet of total torch and torch

leads at 70°F (21°C)

NOTE

The flow rate varies with lead length, torch con-

figuration, ambient temperature, amperage level,

etc.

10. Cooling Capacity

4,000 to 10,000 BTU

NOTE

Maximum value based on “free flow” condition.

11. Coolant Reservoir Capacity

2 gallons

Capable of handling a total of 150 feet of torch lead

length

12. Secondary Water

Tap water can be used as a secondary gas and must

be capable of delivering the following minimums:

• Water pressure of 50 psi (3.5 BAR)

• Flow of 8 gph (35.2 lph)

NOTES

Tap water should only be used as a secondary gas

on machine torches.

The tap water source does not need to be deionized,

but in water systems with extremely high mineral

content a water softener is recommended.

Loading...

Loading...