INSTALLATION PROCEDURES 16 Manual 0-2568

200, 208,

220, or 230

11

12

L3

13

15

14

6

7

L2

8

10

9

1

2

L1

3

5

4

380, 415,

or 460

11

12

L3

13

15

14

6

7

L2

8

10

9

1

2

L1

3

5

4

500, or 575

11

12

L3

13

15

14

6

7

L2

8

10

9

1

2

L1

3

5

4

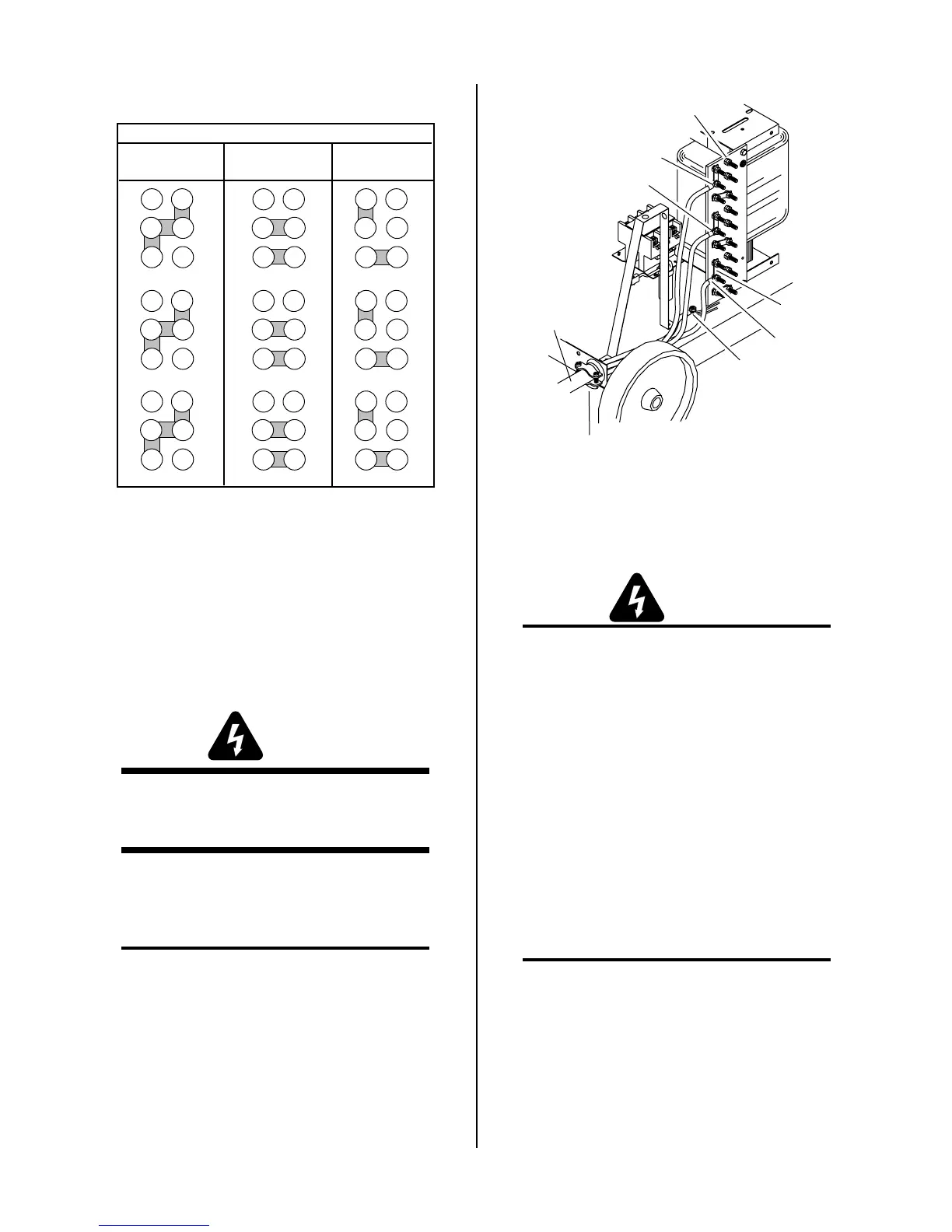

Busbar Connections For Input Voltages

A-00904

Figure 3-5 Busbar Connections

If necessary, reposition the busbars to correspond to

the available line voltage.

3.08 Primary Power Cable

Connections

WARNING

Disconnect primary power at the source before con-

necting the primary power cable to the power sup-

ply.

The primary power cable must be supplied by the end

user and installed to the Power Supply assembly. Rec-

ommended cable sizes are specified in Appendix I.

NOTE

Three-phase operation requires a 3-conductor cable

with ground.

1. Route the primary power cable through the strain

relief fitting in the rear panel of the Power Supply

and tighten strain relief screws.

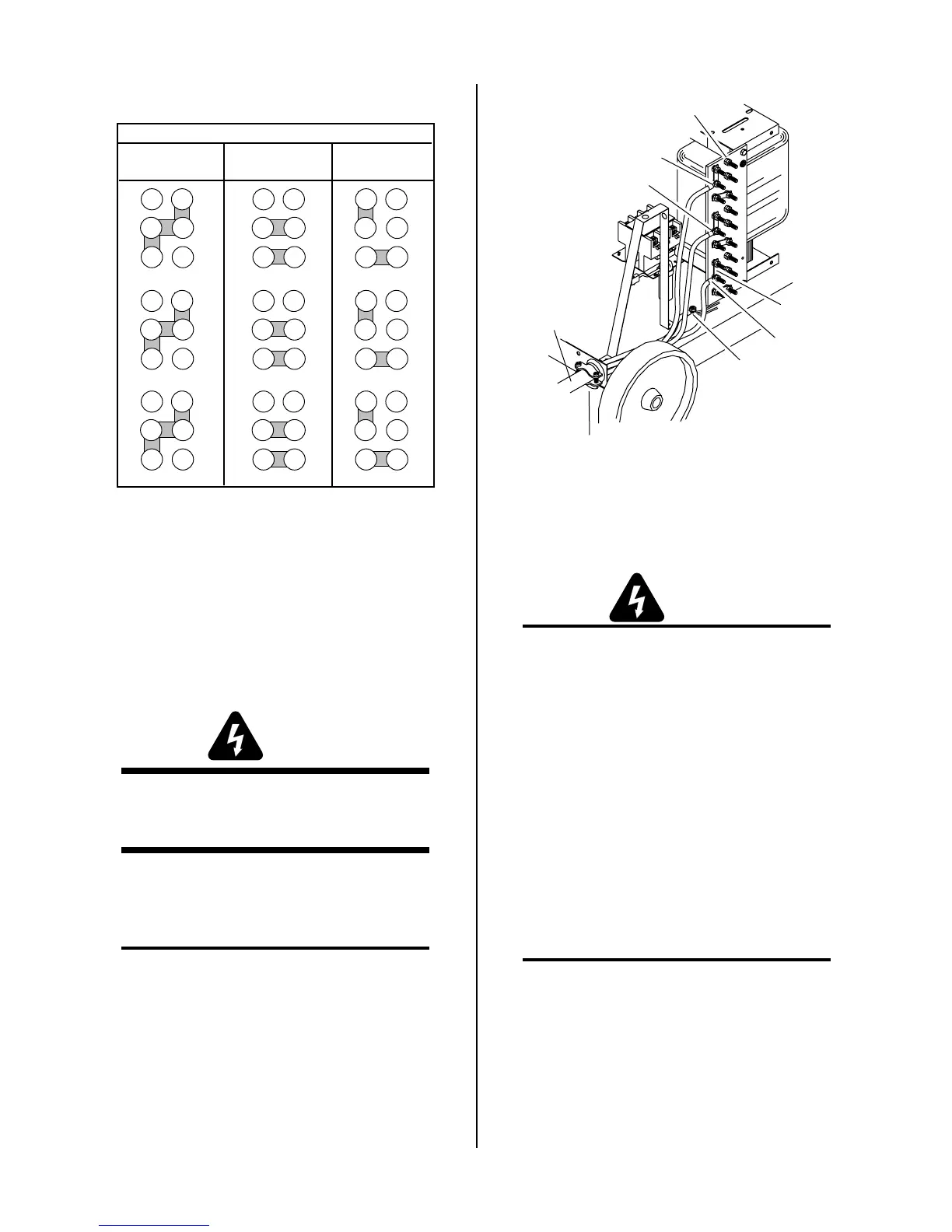

Input Voltage

Terminal Board

L1

L2

L3

Primary Power

Cable

Strain Relief

Fitting

Ground

Connection

Busbars

A-00893

Figure 3-6 Input Voltage Connections

2. Connect the electrical ground wire to the ground

lug on the base of the unit.

WARNING

The electrical ground wire must be connected to

the ground lug in the base of the unit for proper

grounding.

3. Connect the three line leads to the input voltage

terminal board per the following:

• Line 1 to terminal L1.

• Line 2 to terminal L2.

• Line 3 to terminal L3.

4. Tighten all nuts.

3.09 Work Cable And Ground

Connections

NOTE

Refer to Appendix III for a block diagram of a typi-

cal mechanized system work and ground cable con-

nections.

A. Electromagnetic Interference (EMI)

High frequency pilot arc initiation generates a certain

amount of electromagnetic interference (EMI), commonly

called RF noise. This RF may interfere with other elec-

tronic equipment such as CNC controllers, etc. The sys-

Loading...

Loading...