CleaningtheNozzleBodyand

Check-ValveDiaphragm

ServiceInterval:Yearly—Cleanthenozzlebody

andcheck-valvediaphragm.Clean

thenozzlebodyandcheck-valve

diaphragmifyounoticethata

nozzle(s)isdrippingafterthe

sectionswitch(es)isshutoff.

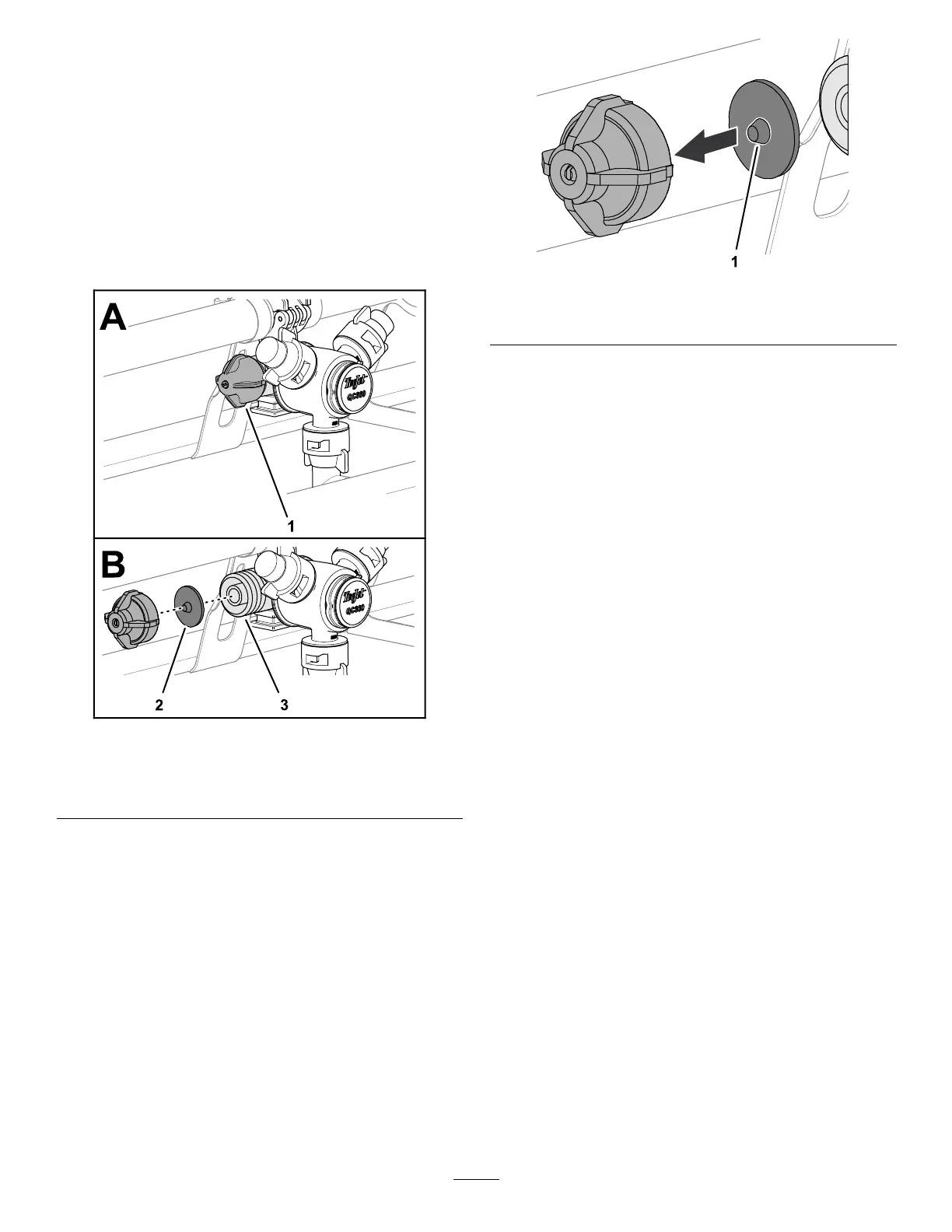

1.Rotatethediaphragmcapcounterclockwiseand

removethecapfromthenozzlebody(Figure

32).

g239582

Figure32

1.Diaphragmcap3.Nozzlebody

2.Check-valvediaphragm

2.Removethecheck-valvediaphragmfromthe

capornozzlebody(Figure32).

3.Cleanthecap,diaphragm,andnozzlebodywith

cleanwater(Figure32).

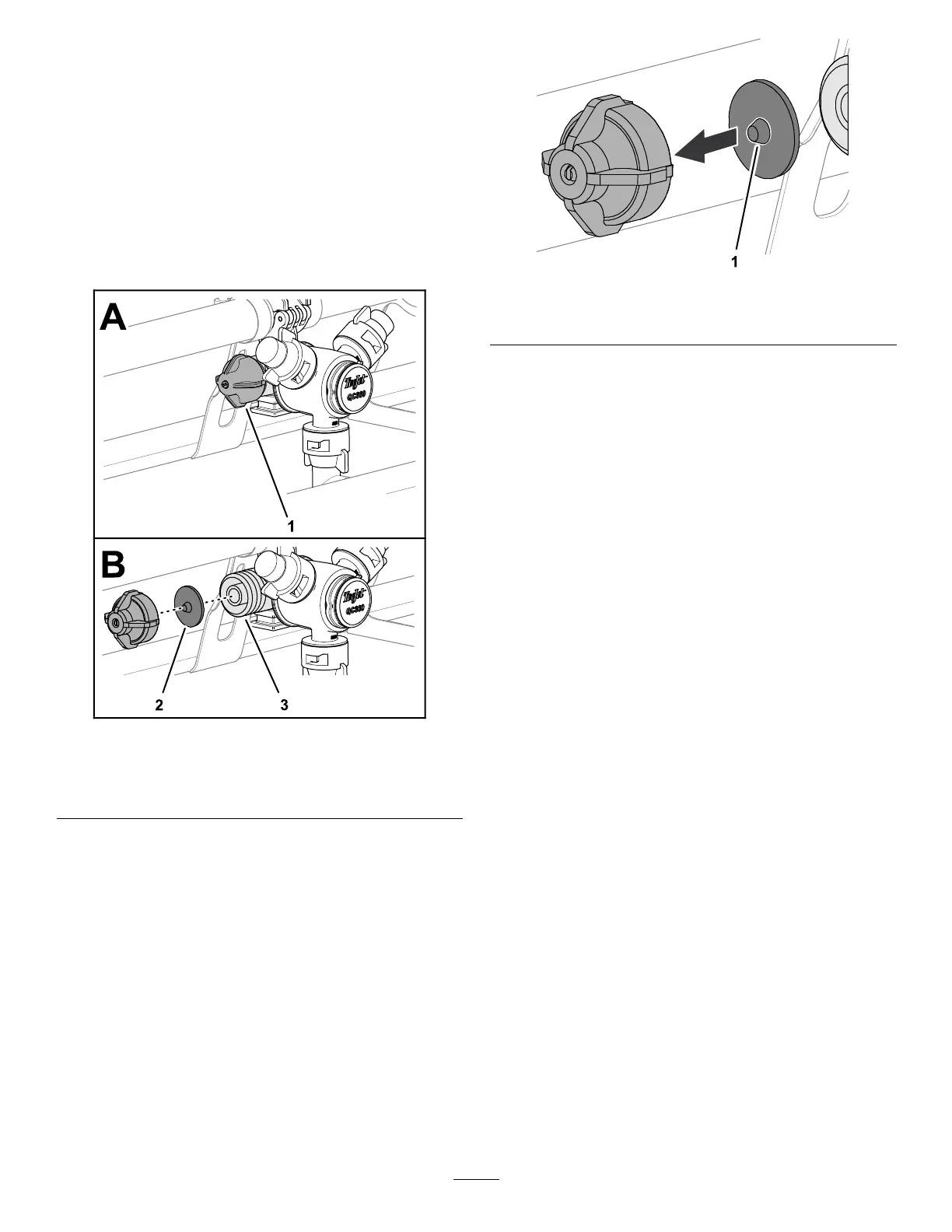

4.Assemblethediaphragmintothecapwiththe

nibofthediaphragmtowardthecap(Figure32).

g239583

Figure33

1.Nib(diaphragm)

5.Assemblethecapanddiaphragmtothenozzle

bodyandtightenbyhand(Figure32).

6.Repeatsteps1through5fortheotherspray

nozzles.

ConditioningtheSpraySystem

ServiceInterval:Aftereachuse—Conditionthespray

systemattheendofeachdailyuse.

ConditionerSpecication

Conditionerspecication:propyleneglycol

"non-toxicRVantifreeze”withcorrosioninhibitor

Important:Useonlypropyleneglycolwith

corrosioninhibitor.

Donotuserecycledpropyleneglycol.Donotuse

ethyleneglycolbaseantifreeze.

Donotusepropyleneglycolwithsolublealcohols

(methanol,ethanolorisopropanol)orbrines

added.

PreparingtheConditioner

1.Movethemachinetoalevelsurface,setthe

parkingbrake,shutofftheengine,andremove

thekey.

2.Addconditionertothetankasfollows:

•Forreadytouse(premixed)propyleneglycol

RVantifreeze—add10gallonsofpropylene

glycolRVantifreezetothetank.

•ForconcentratedpropyleneglycolRV

antifreeze,performthefollowingsteps:

A.Adda10gallonmixtureofpropylene

glycolRVantifreezeandwaterintothe

sprayertank.Preparedtheantifreeze

mixtureasinstructedmanufacturerfor

aconcentrationratedfor-45°C(-50°F)

minimum.

39

Loading...

Loading...