Lubrication

Greasing the Bearings

Service Interval : Every 25 hours —Grease the caster

wheel bearings (more often in sandy

soil conditions).

Grease T ype: No. 2 lithium grease

1. Park the machine on a level surface, disengage

the blade-control switch, and move the

motion-control levers outward to the P ARK

position.

2. Shut of f the engine, remove the key , and wait

for all moving parts to stop before leaving the

operating position.

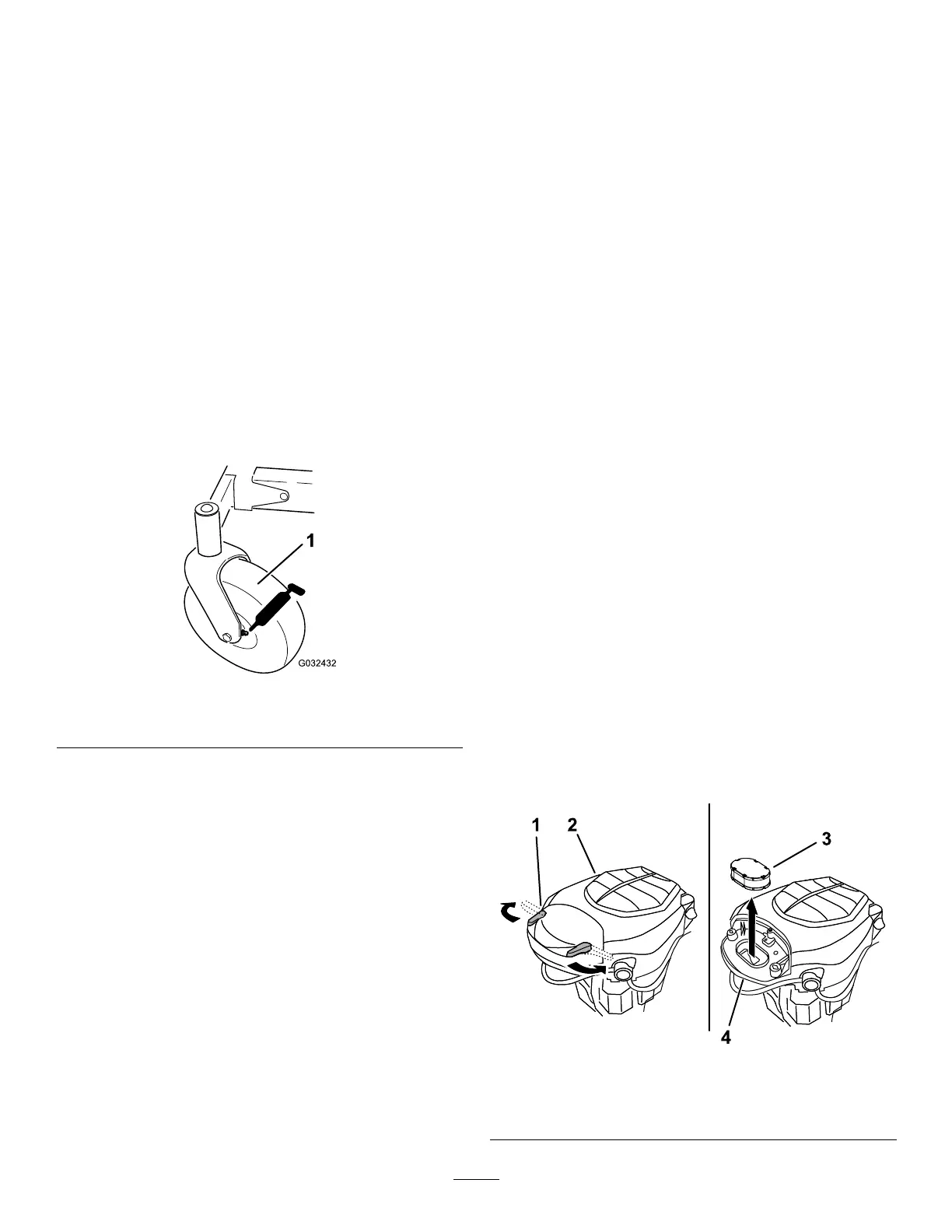

3. Clean the grease ttings ( Figure 37 ) with a rag.

Note: Scrape any paint of f the front of the

tting(s).

g032432

Figure 37

1. Front caster tire

4. Connect a grease gun to each tting ( Figure 37 ).

5. Pump grease into the ttings until grease begins

to ooze out of the bearings.

6. Wipe up any excess grease.

Engine Maintenance

Engine Safety

• Keep your hands, feet, face, other body parts,

and clothing away from the muf er and other hot

surfaces. Allow engine components to cool before

performing maintenance.

• Do not change the engine governor speed or

overspeed the engine.

Servicing the Air Cleaner

Service Interval : Every 25 hours —Clean the

air-cleaner foam element (more

often in dusty , dirty conditions).

Every 100 hours —Replace the air-cleaner foam

element (more often in dusty , dirty conditions).

Note: Service the air cleaner more frequently (every

few hours) if operating conditions are extremely dusty

or sandy .

Removing the Foam and Paper

Elements

1. Park the machine on a level surface, disengage

the blade-control switch, and move the

motion-control levers outward to the P ARK

position.

2. Shut of f the engine, remove the key , and wait

for all moving parts to stop before leaving the

operating position.

3. Clean around the air-cleaner cover to prevent

dirt from getting into the engine and causing

damage.

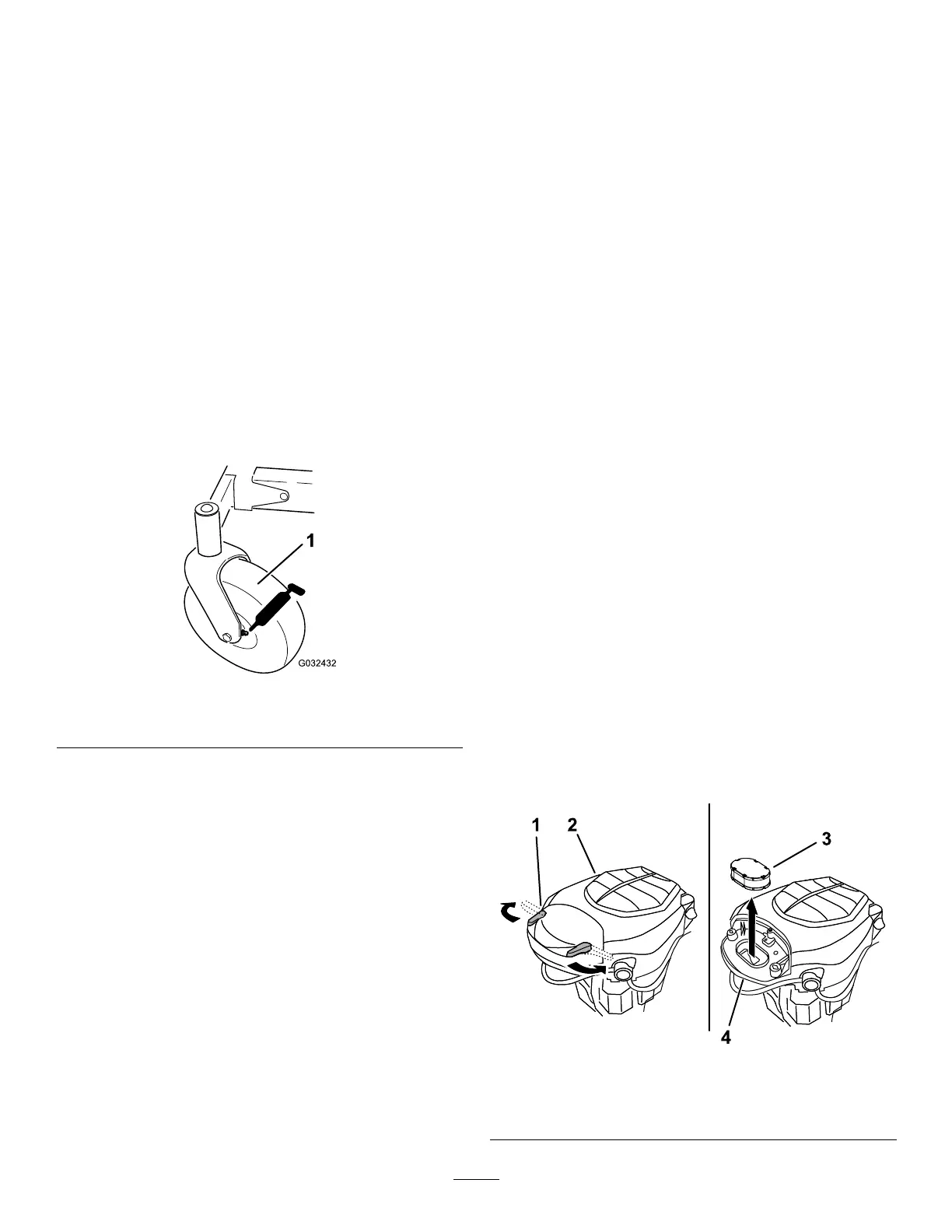

4. Rotate the latches outward and remove the

cover to access the air-cleaner elements.

g333875

Figure 38

1. Latch 3. Air-cleaner elements

2. Engine 4. Air-cleaner base

33

Loading...

Loading...