Fault elimination

What to do if...

97

Fault elimination

This section provides information on what to do if a fault occurs. An identified

fault can have various possible causes.

For instructions on the respective fault clearances that may be carried out by

technical personnel as defined in "Personnel qualification", please refer to

the section "Repair". It is essential to observe the safety instructions in the

respective section.

What to do if...

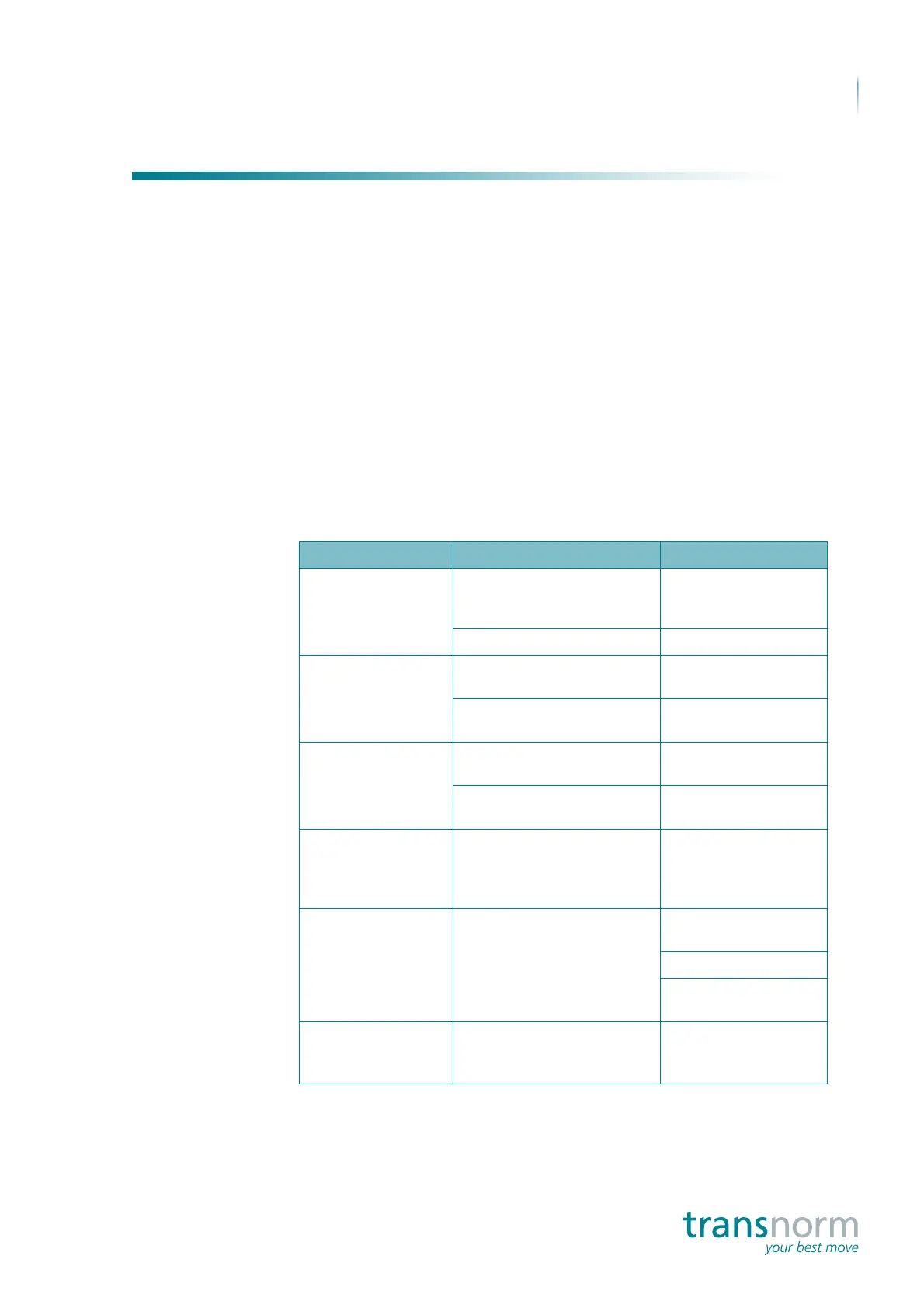

Mechanical faults

Identified fault Possible cause Action to remedy the fault

Machine shuts down Power supply interrupted,

error message

Have technical personnel

establish and eliminate

the problem

Motor defective Replace the motor

Machine shutdown with

running motor

Drum journal is broken Replace the corre-

sponding drum

Belt tension is too low Tension and adjust the

belt

Belt movement jerky Belt tension is too low Tension and adjust the

belt

Belt is blocked by foreign

objects

Remove foreign objects

Belt bulges Belt overstretched or incor-

rectly tensioned

Tighten and adjust the

belt,

If necessary, replace the

belt

Belt generates grinding

noise

Belt rubbing on the edges of the

bed

Tighten and adjust the

belt

Align the bed

Realign the drive drum /

deflection drum

Noise development /

leakage on the deflec-

tion bearings

Drum journal is turning in

internal ring of bearing

Bearing defective

Replace the bearing,

Replace the drum if

necessary

Loading...

Loading...