4-5

Section

4.4 Lubrication

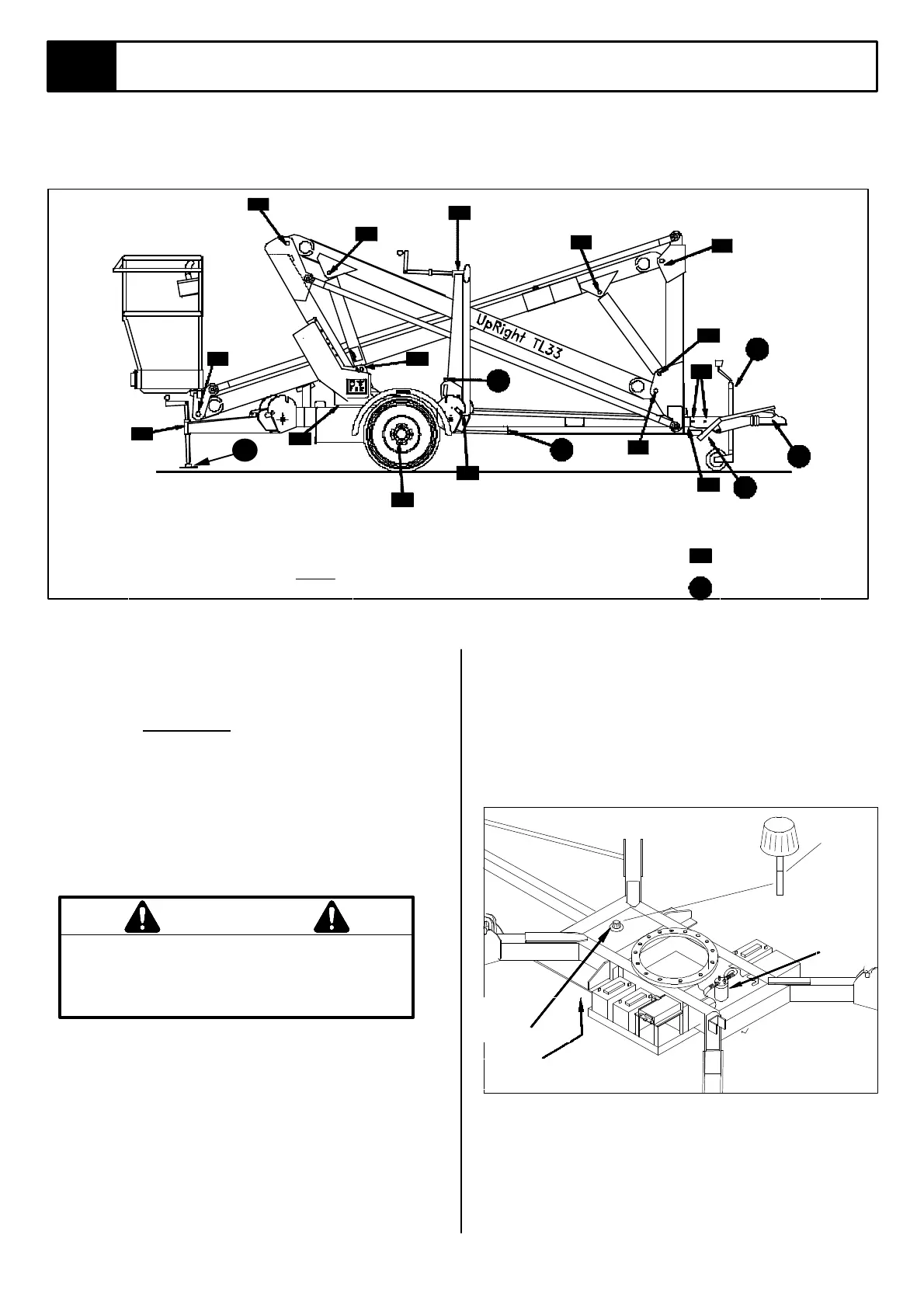

Refer to Figure 4-1 for location of items that require lubrication service. Refer to the appropriate

sections for lubrication information on the Hydraulic Oil Tank and Filter.

Figure 4-1: Lubrication Points

HYDRAULIC OIL TANK AND FILTER

Fluid Level

With platform fully lowered, oil should be visible on the

dipstick, if not fill the tank until oil registers on the dipstick.

DO NOT fill above the upper line or when the platform is

elevated.

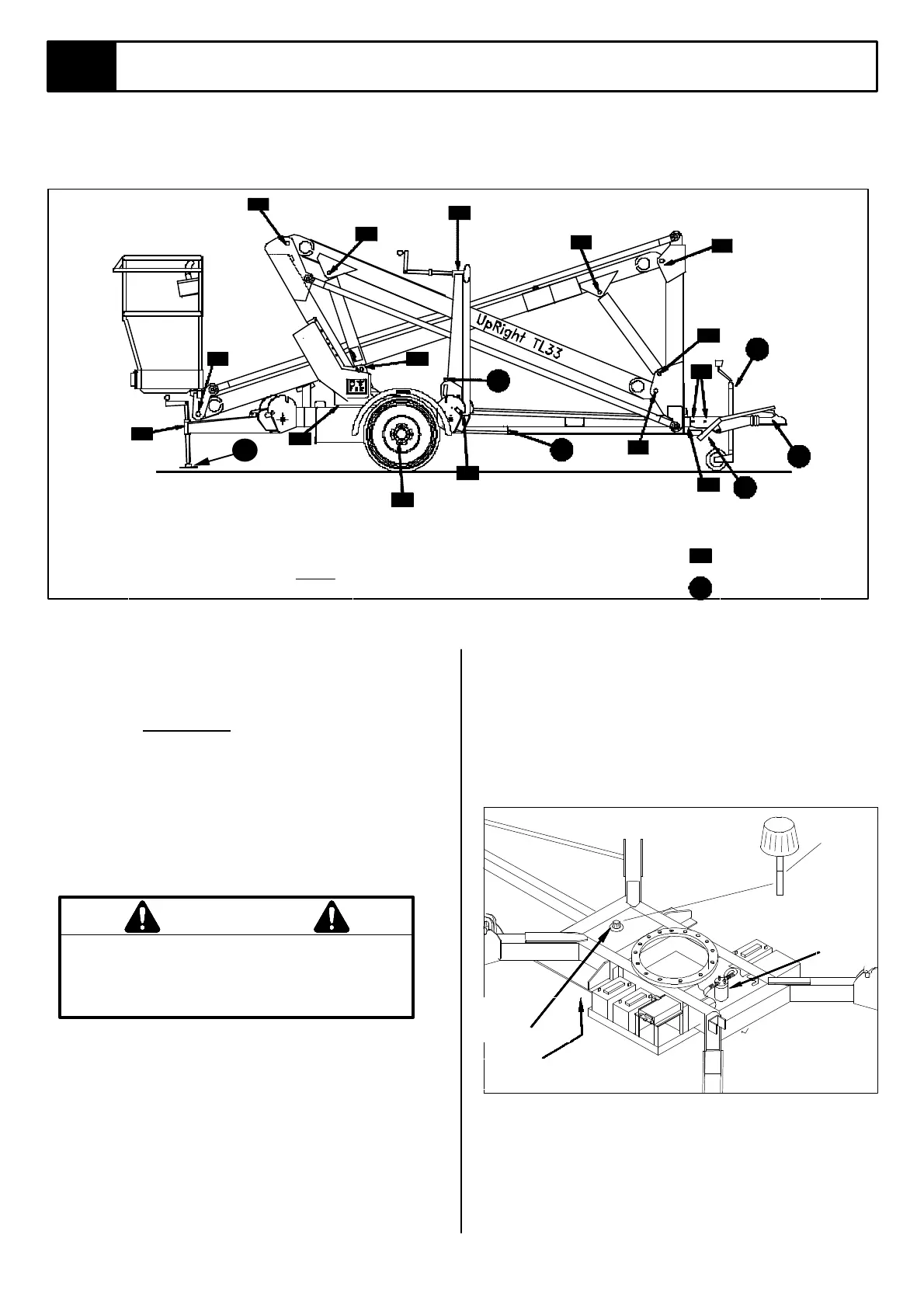

Oil and Filter Replacement (Figure 4-2)

1. Operate the platform for 10-15 minutes to bring the

hydraulic oil up to normal operating temperature.

The hydraulic oil may be of sufficient temperature

to cause burns. Wear safety gloves and safety

glasses when handling hot oil.

2. Provide a suitable container to catch the drained oil.

Hydraulic tank has a capacity of 8 Litres.

3. Remove the drain plug under the tank and allow all

oil to drain

4. Clean the magnetic drain plug and reinstall.

5. Unthread the the filter from the filter head.

6. Applyy a thin film of clean hydraulic oil (ISO No. 46) to

the gasket of the replacement filter.

7. Thread the replacement filter onto the filter head until

the gasket makes contact then rotate the filter a

further 3/4 of a turn.

8. Fill the hydraulic reservoir with hydraulic oil (see

Section 1-2) checking level with dipstick.

9. Recycle used oil as per local environmental

regulations.

Figure 4-2: Oil and Filter Replacement

Grease Nipple Locations

2 per Outrigger :8

2 per Boom :4

2 per cylinder :4

2 on Tow Hitch :2

Total :18

FILTER

FILLER CAP

WITH

DIPSTICK

DRAIN PLUG UNDER

CHASSIS HERE

MAX

Oil

Grease

Loading...

Loading...