4-13

Section

4.10 Braking System

PRINCIPLES OF OPERATION

The Auto Reversing arrangement is fitted to each wheel

brake. One 'Shoe' in each brake is fitted with a device that

allows the shoe to slide down on cams or rollers when the

brake drum is rotated in reverse, thus reducing the overall

brake diameter and resistance to movement. In forward

motion, the brake shoe is drawn back to its normal

operating position for forward braking.

To overcome the tendency for the auto-reverse function to

disengage the brakes when parked facing up-hill, an

'energy-store' in the form of a spring in the handbrake lever

mechanism is fitted. This maintains sufficient pressure on

the brakes in the reverse mode, preventing the TL33 from

moving backwards.

NOTE: The handbrake must be applied sufficiently to

ensure that the spring energy store is fully

compressed. Prior to the brakes being 'bedded in' (850

Km or 500 miles from new or from brake shoe change)

care must be taken during normal braking, and when

using the handbrake for parking it is advisable to

chock the wheels for safety.

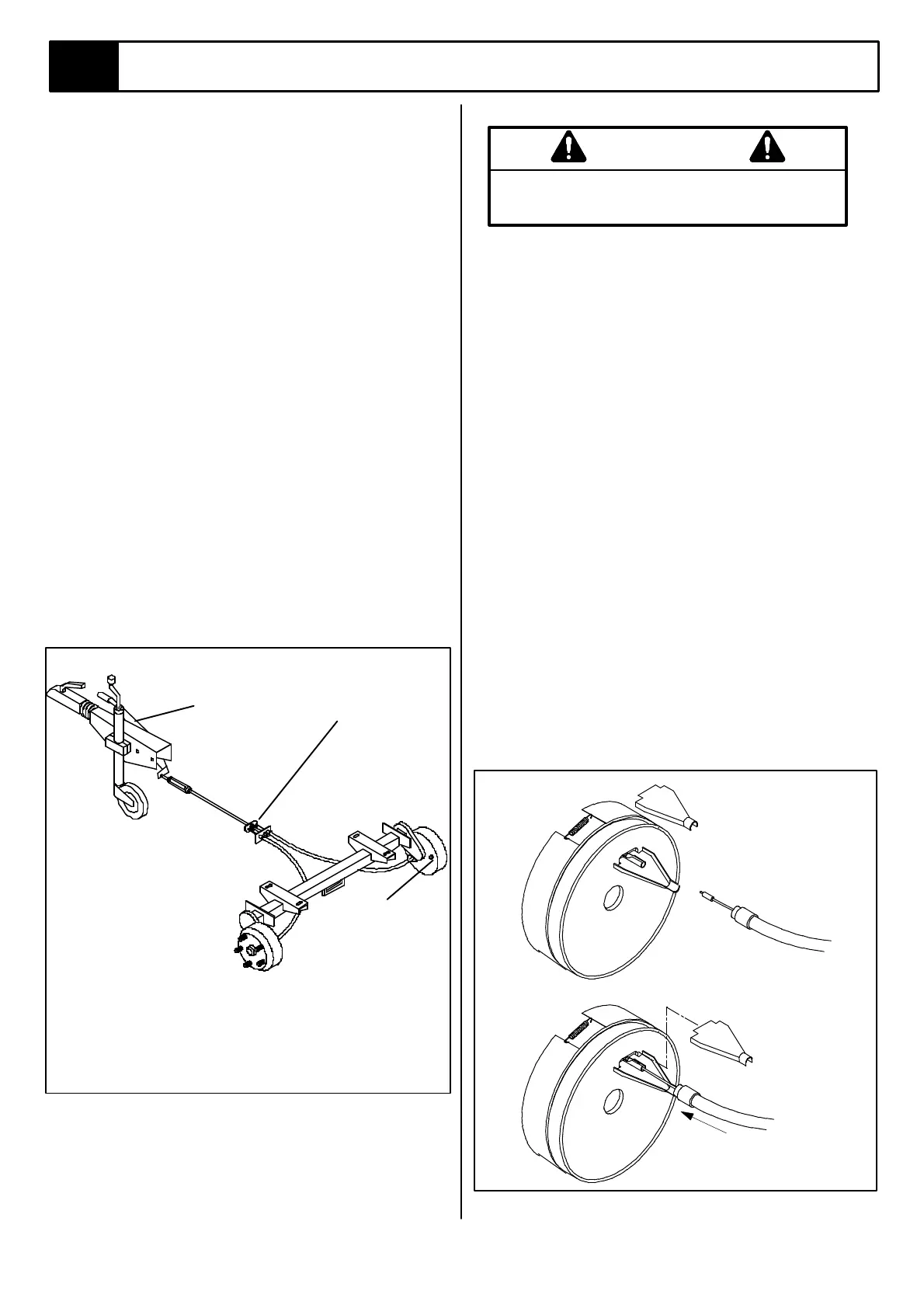

Figure 4-11: Braking Arrangement

ADJUSTMENT OF WHEEL BRAKES

Take care not to inhale brake dust when working

on brakes. Wear a filter mask.

Position the machine on level ground. Ensure handbrake is in the

fully OFF position.

1. Jack wheels clear of the ground.

2. Ensure that handbrake cables are slacked.

3.. Rotate wheels in the forward direction (clockwise on the

right hand side of trailer, anti clockwise on the left hand

side) and tighten adjustment nut (Fig. 4-11 item 1) in a

clockwise direction until hubs will no longer rotate.

4. Slacken the adjustment nut until very slight resistance

is felt between the brakes and brake drum.

5. When adjusting the brakes, ensure that the shoes only

just touch the inside of the brake drums. In order for the

system to work correctly in the reverse mode, the brake

drums must rotate in reverse sufficiently to disconnect

and collapse the auto reverse shoe. The moving tube

inside the coupling must continue to stroke fully and

rest on a "stop" without re-applying the brakes. If the

brakes are adjusted too tightly to the drums then the

coupling will again apply the brakes and prevent further

reverse movement.

6. Re-adjust cables & test function.

CHANGING WORN OR DAMAGED BRAKE

CABLES

1. Check brake cable where it enters brake. If it ends in a

collar that fits over the cable entry tube then the cables

are of the detachable type.

2. To change the cable, slacken and drop cable end from

the Equalizer plate (Fig. 4-11 item 3) and detach cables

from drum as shown in Figure 4-12 (a) .

3. To refit, reverse the procedure.

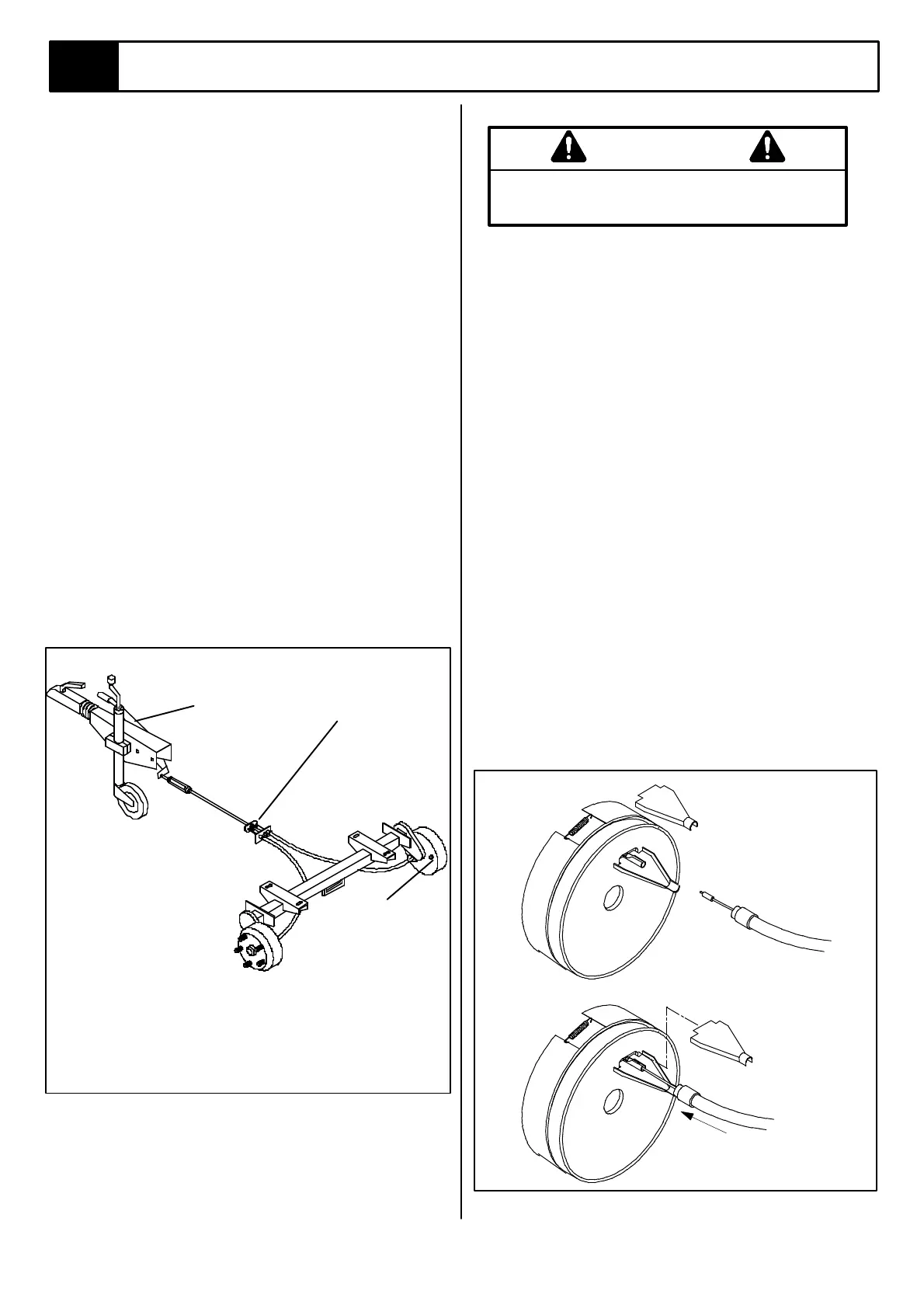

Figure 4-12: Replace Brake Cable

3

1

2

1. Brake Shoe Adjustment

2. Handbrake

3. Equalizer plate

WARNING

(b)

(a)

Remove top half of

cable bracket and

remove cable.

Replace top half of

cable bracket and

over bracket

assembly.

Loading...

Loading...