TL33 Work Platform 2-1

Section

2.1 Preparation for use

Read and familiarise yourself with all operating

instructions before attempting to operate machine.

1. Check Hydraulic oil level.

2. Check that batteries are charged.

2.2 Preparation for Shipment

1. Lubricate machine per lubrication instructions in

Section 4.4, Maintenance.

2. Fully Lower the platform.

3. Stow all 4 outriggers.

4. Disconnect the negative (-) battery cable from the

battery terminal.

2.3 Forklifting the Work Platform

NOTE: Lifting is for loading and unloading only.

NOTE: The TL33 is not designed to be forklifted,

and does not have provision on the chassis

to allow this method of lifting. Upright

recommend the procedure below for

handling the machine.

See specifications for weight of work

platform and be certain that lifting

apparatus is of adequate capacity

to lift platform.

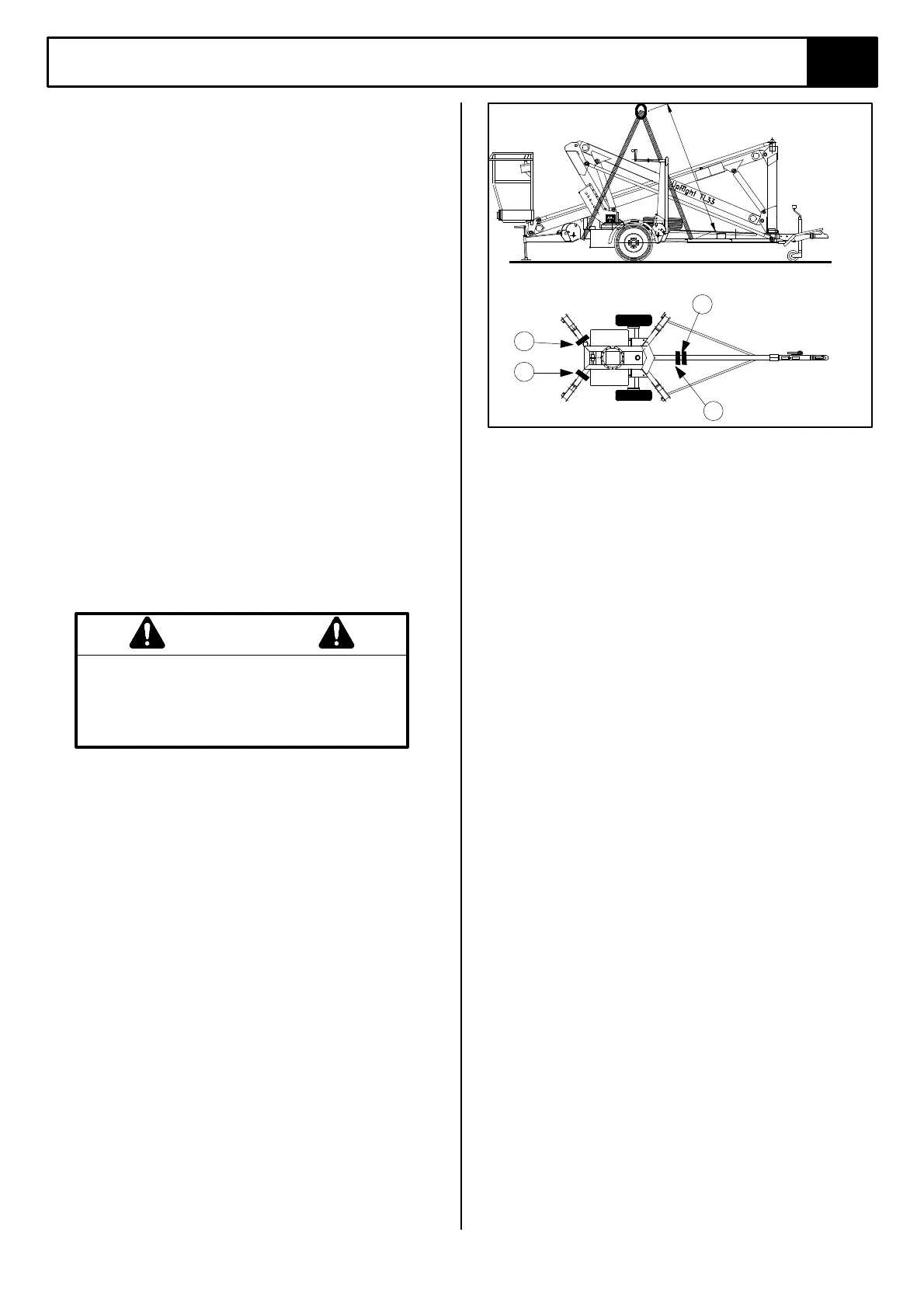

2.4 Lifting the Work Platform

The Tl33 may be lifted by an overhead hoist/crane in the

following manner:

Four lifting straps capable of safely supporting the total

weight of the TL33 (1209Kg), and at least 220cm long

are required. This minimum length is important to ensure

the correct lifting angle.

The straps should be positioned as shown in Figure2-1.

The two rear lifting slings should be positioned inside the

“quadrant” outrigger mounting plates. Care must be

taken to ensure the slings do not damage the cable for

the outrigger limit switches (Positions 1 & 2).

the front lifting slings should be positioned under the

towing beam, directly in front of the brake cable anchor

plate. Note that two straps are essential at this point -

one must pass each side of the lower boom and be

positioned between the boom and the tension bars on

either side. (Position 3 & 4).

Care must be taken to avoid damage to covers and other

equipment on the machine.

Figure 2-1: Lifting the TL33

2.5 Transport

The TL33 is a road approved vehicle and therefore may

be transported behind a motor vehicle of suitable towing

capacity.

If the TL33 is to be transported by other means then it

must be securely tied down to the transporting unit at

several points.

Recommended securing points are the four outrigger

support members on the chassis and the towbar. Further

securing points should be used if the terrain on which the

unit is travelling is rough or uneven.

ALWAYS ensure that the handbrake is fully applied and

that all the booms are FULLY stowed.

2.6 Storage

No preparation is required for normal storage. Regular

maintenance per Table 4-1 should be performed. If The

work platform is to be placed in long term storage (dead

storage) use the following preservation procedure.

PRESERVATION

1. Clean painted surfaces. If the painted surface is

damaged, repaint.

2. Fill the hydraulic tank to operating level with the

platform fully lowered. Fluid should be visible on

the dip stick.

3. Coat exposed portions of cylinder rods with a

preservative such as multipurpose grease and wrap

with barrier material.

4. Coat all exposed unpainted metal surfaces with

preservative.

BATTERIES

1. Disconnect the battery ground cable and secure to

the chassis.

2. Disconnect the remaining battery leads and secure to

the chassis.

3. Remove the batteries and place in alternate service.

CAUTION

Minimum sling length

220cm

Loading...

Loading...