3-8

Section

EMERGENCY ROTATION

The following procedure for rotation of the elevating

assembly in an emergency situation should be carried

out only by a qualified service engineer:

1. Ensure booms are lowered as far as possible using

emergency lower valves.

2. Remove cap on rotation gearbox shaft cover.

3. Apply a 13 mm. socket wrench to shaft and turn to

rotate elevating assembly.

4. Remove wrench.

5. Reinstall protective cap.

CONTROL FROM GROUND LEVEL

1. Ground Controls are fitted at the base of the boom.

These should only be used when no operator is in the

platform (for maintenance/ service purposes), or if the

operator has become incapacitated.

2. Turn key switch to CHASSIS (to the right).

3. Use the appropriate switch to raise/lower Boom 1,

Boom 2 or rotate as required.

AFTER USE EACH DAY

1. Ensure that the platform is fully lowered.

2. Park the machine on level ground, preferably under

cover, secure against vandals, children or unauthorised

operation. Apply handbrake.

3. Turn key switch to OFF and remove key to prevent

unauthorised operation.

4. Recharge batteries in accordance with the instructions

in section 4.3.

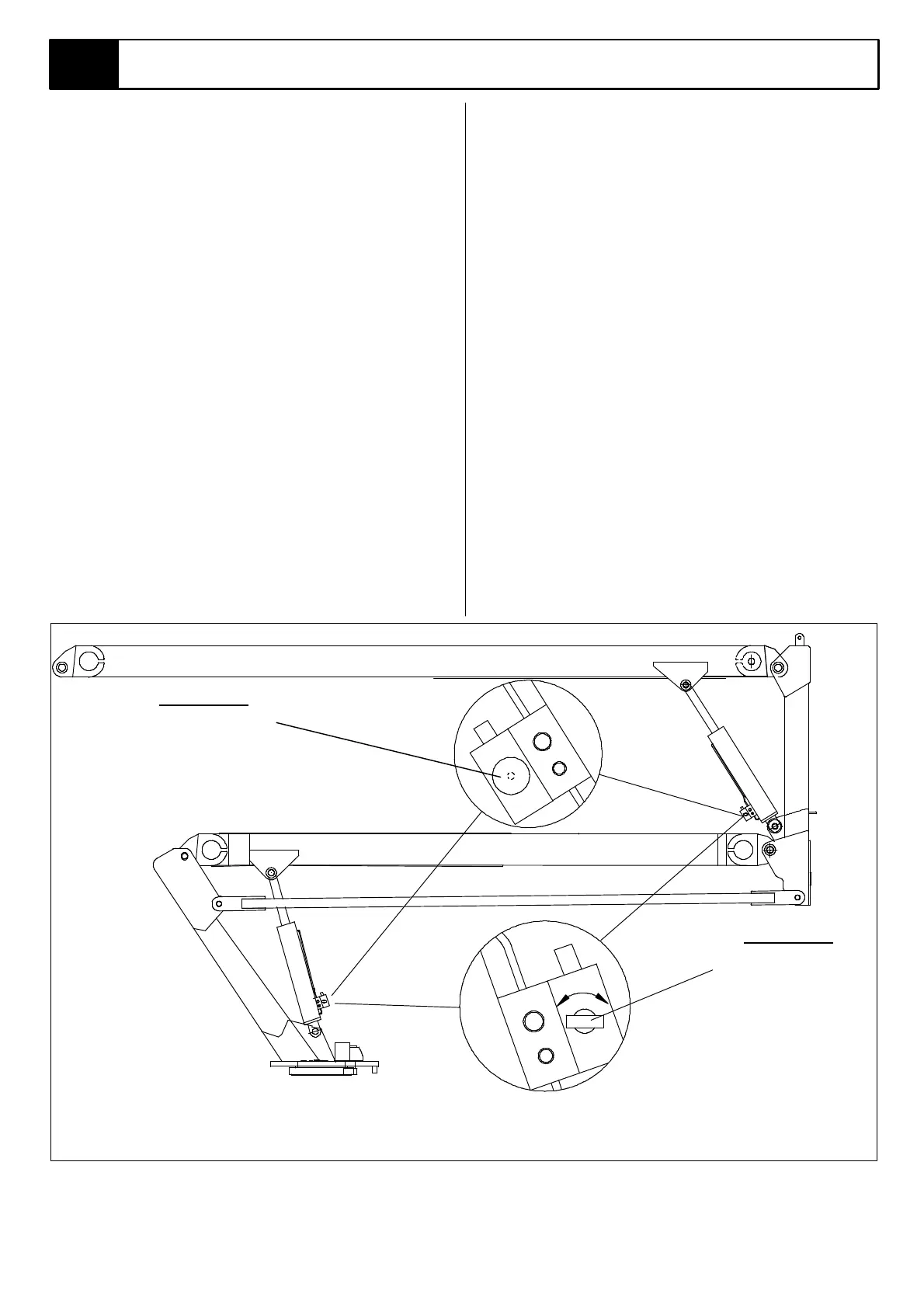

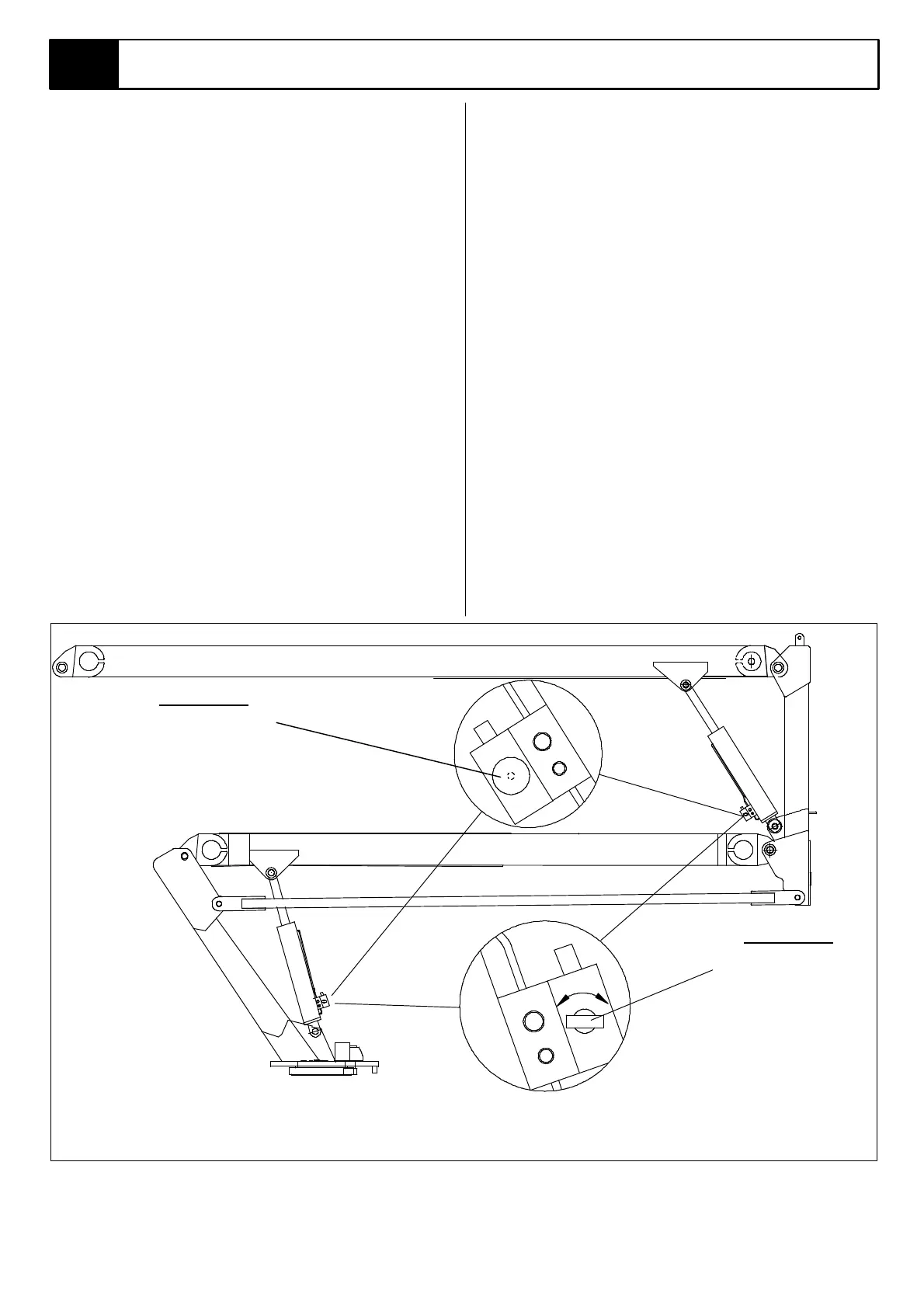

Figure 3-4: Emergency Lowering Valves

TURN TYPE

Knob on Emergency

Lowering valve.

anti-clockwise to

allow oil out of

cylinder full-bore and

lower boom

PUSH TYPE

Knob on Emergency

Lowering valve.

Push anti-clockwise

to allow oil out of

cylinder full-bore and

lower boom

Loading...

Loading...