TL33 Work Platform 4-6

4.5 Setting Hydraulic Pressures

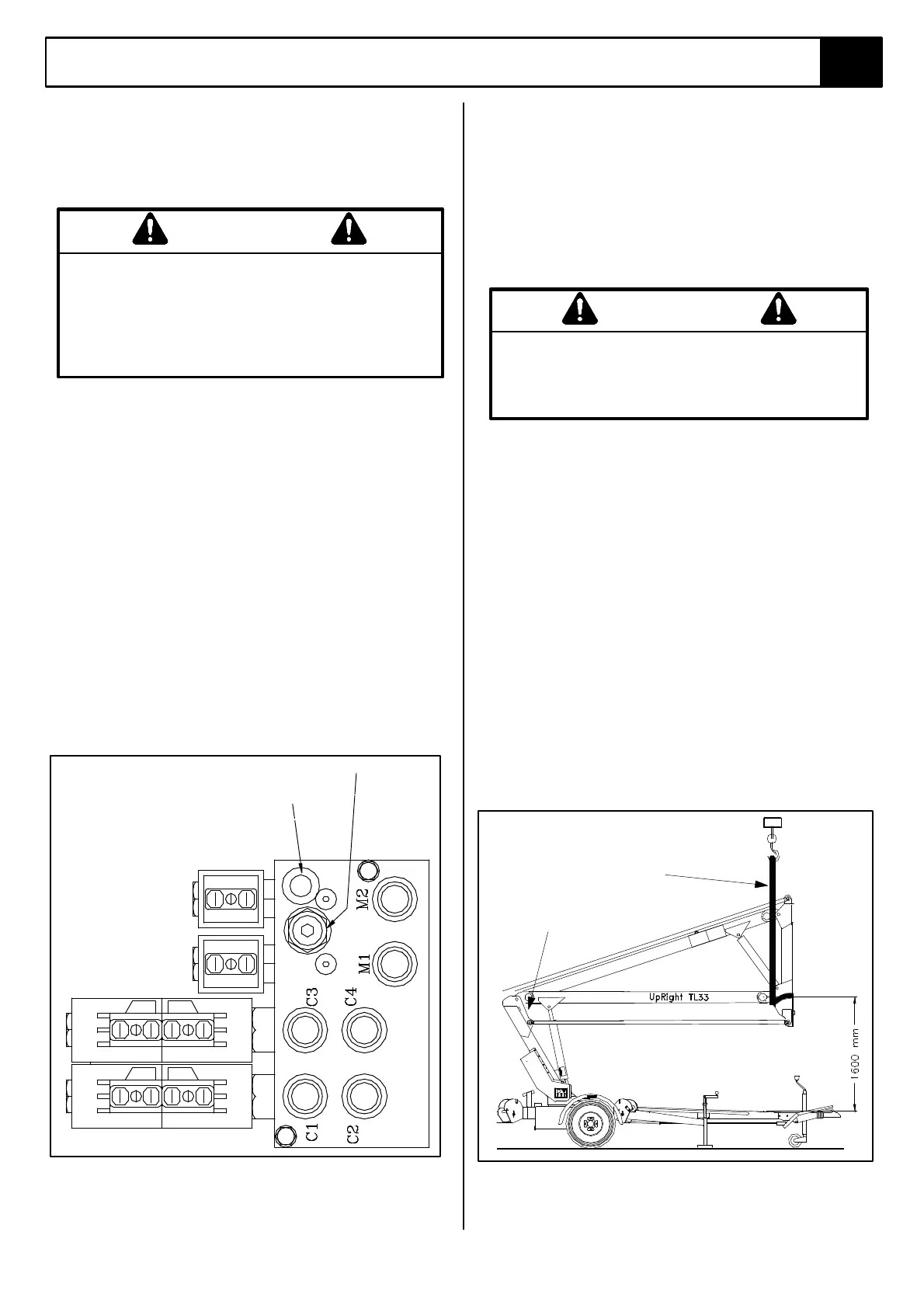

(Figure 4-3)

Check the hydraulic pressures whenever the pump,

manifold or relief valve have been serviced or

replaced.

The hydraulic oil may be of sufficient temperature

to cause burns. Wear safety gloves and safety

glasses when handling hot oil.

The oil in the hydraulic system is under very high

pressure which can easily cause severe cuts. Obtain

medical assistance immediately if cut by hydraulic oil.

MAIN RELIEF VALVE (Figure 4-3)

1. Operate the hydraulic system for 10-15 minutes to

warm the oil.

2. Remove the cover from the 1

st

post.

3. Insert pressure gauge into high pressure gauge port

on top of front face of main manifold block.

4. Loosen locknut on main relief valve and turn adjusting

screw counter clockwise two full turns.

5. Operate lower boom down function switch at lower

controls and keep it activated.

6. Slowly turn the main relief valve adjusting screw

clockwise until the pressure gauge reads 140 Bar

(2030 p.s.i.) pressure.

7. Release the boom down switch.

8. Tighten locknut on main relief valve while holding

the adjusting screw in position.

Figure 4-3: Main Manifold Block

4.6 Maintenance on Elevating Assembly

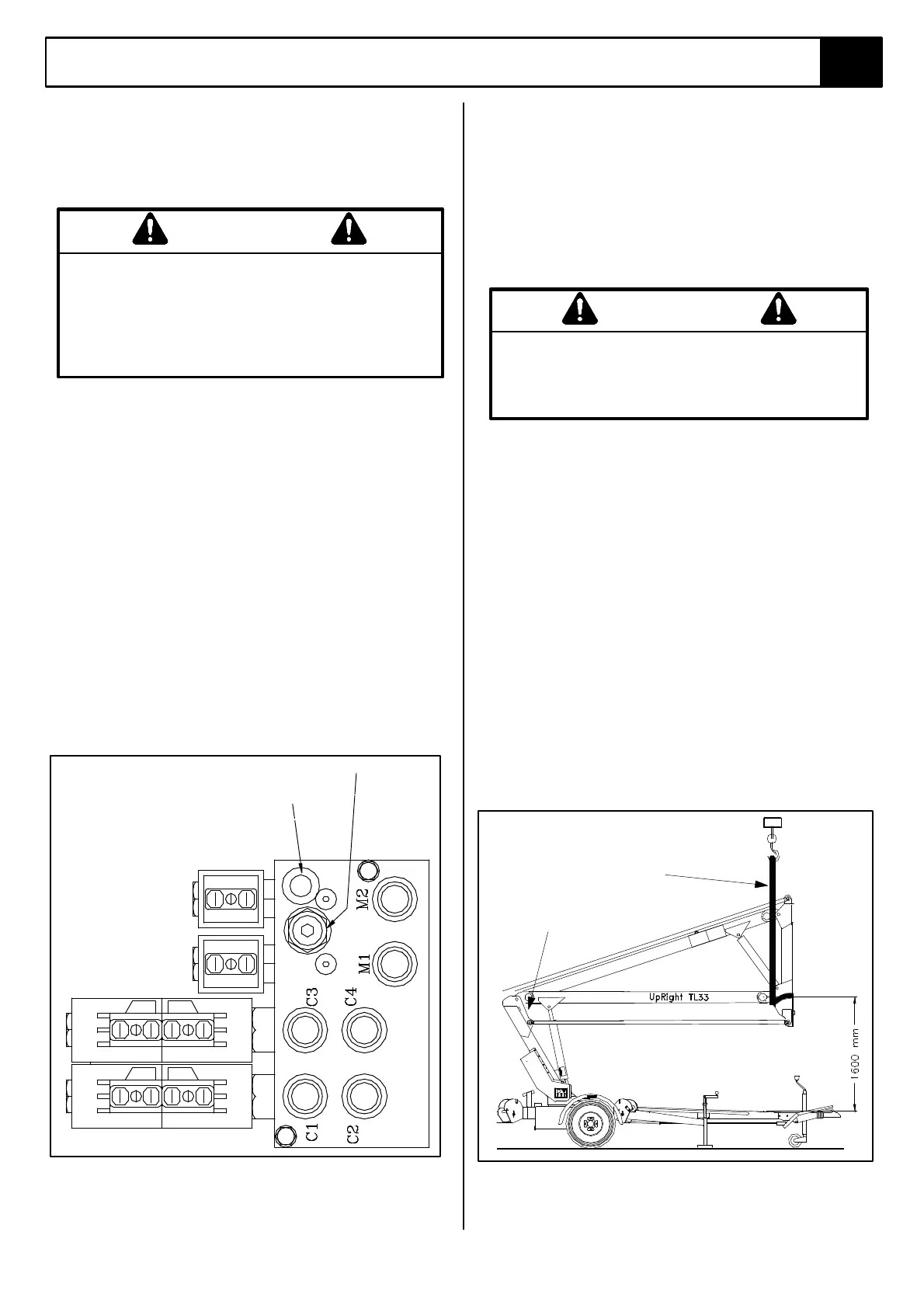

(Figure 4-4)

The only time the Elevating Assembly needs to be elevated to

allow service work to be carried out is when working on the Slew

Limit Switch.

All other work (Bearings, Cylinders, Booms & Tension Bars) can

and must be performed with the Elevating Assembly in the

stowed position.

When working on the Slew Limit Switch follow the procedure

detailed below.

BEFORE entering Elevating Assembly while performing

maintenance on work platform while elevated, ensure that

Elevating Assembly properly

supported by suitable cranage of adequate capacity.

(Recommended 1 tonne capacity crane and sling.)

INSTALLATION

1. Park the work platform on firm level ground.

2. Verify Platform Emergency Stop Switch is ON.

3. Turn Key Switch to"'Ground Control" position.

4. Position Lower Control Boom 1 Switch to "UP" and

elevate until the lower boom is 1600mm (63inches)

above the tow bar.

5. Place a sling of 1000kg load capacity at the end of the

lower boom and first post. Ensure sling is secured so

that it will not slip up along the boom.

6. Push Lower Control Boom 1 Switch to "DOWN" and

gradually lower the platform until Lower Boom is supported

by the sling.

REMOVAL

1. Push Lower Control Boom 1 Switch to "UP" position

and gradually raise the platform until the sling can be

removed.

2. Remove the sling.

3. Push Lower Control Boom 1 Switch to "DOWN" and

completely lower platform.

4. Turn Key Switch to "OFF"

Figure 4-4: Supporting the Elevating Assembly

WARNING

WARNING

MAIN RELIEF

VALVE

GAUGE PORT

SLEW LIMIT SWITCH

SLING

1 TONNE CAPACITY

CRANE / WINCH

Loading...

Loading...