VENTO MOTORCYCLES

Rev no.01/ page 46of 84

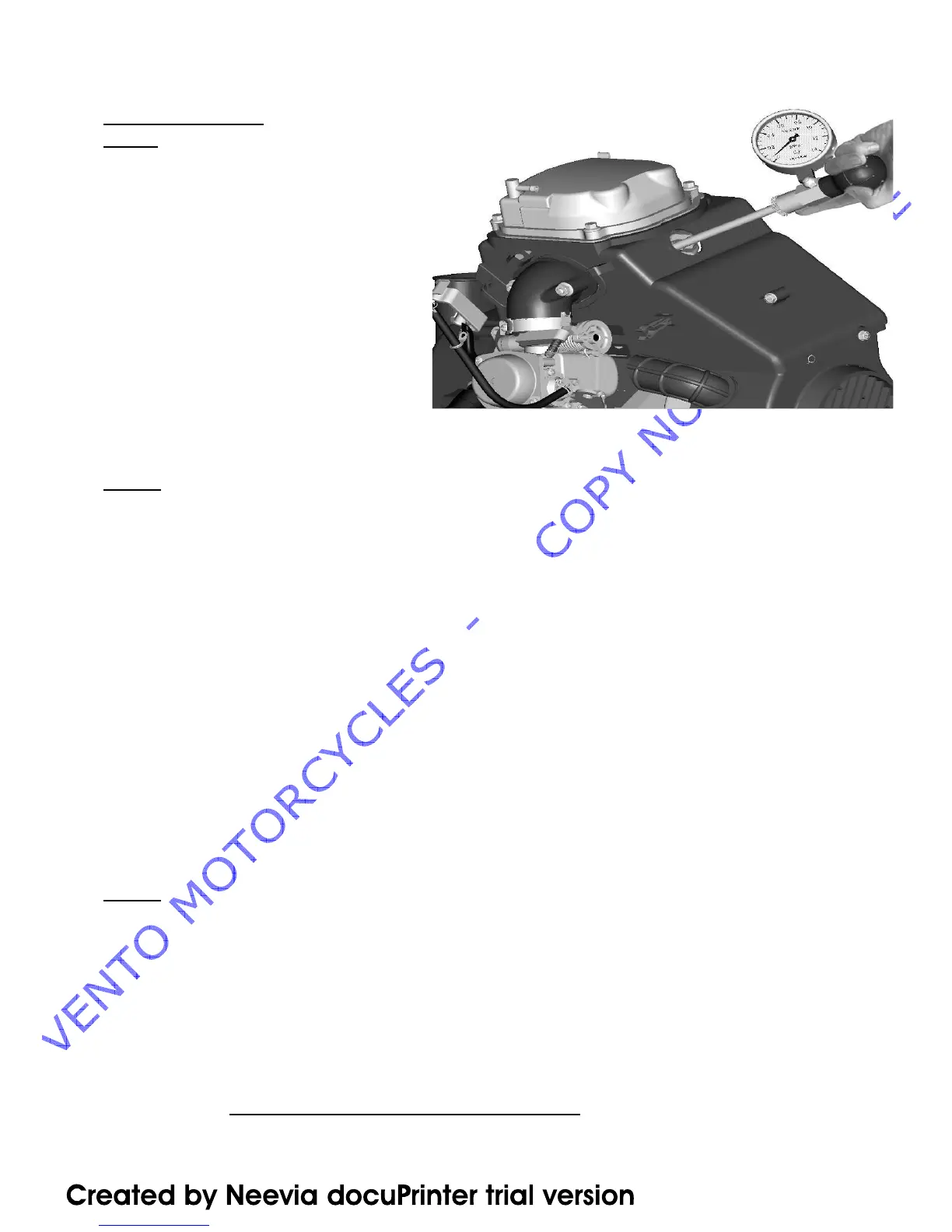

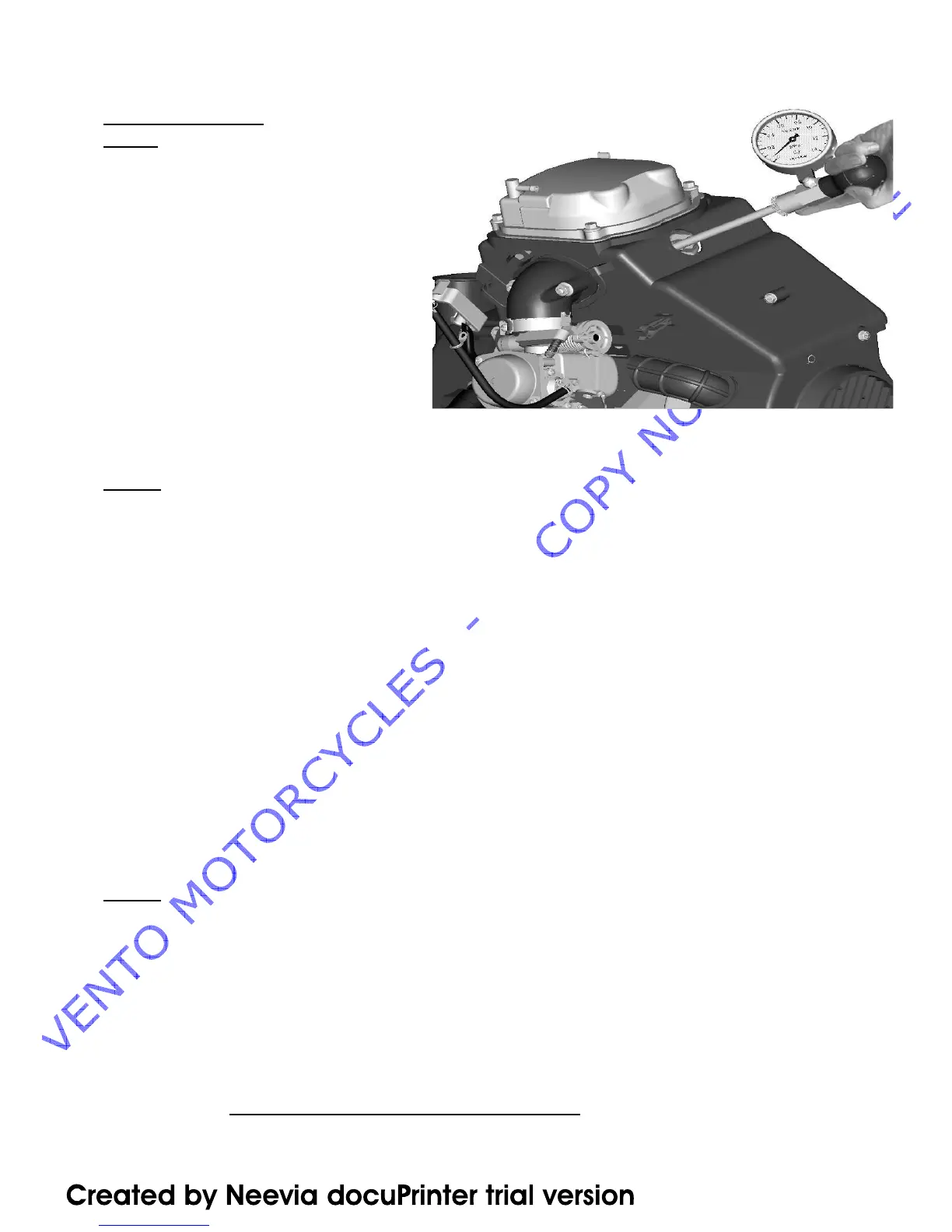

TESTING PROCEDURE

STEP -1

1 Warming up the engine to normal running

temperature (hot condition).

2 Remove spark plug and connect

compression pressure gauge.

3 Ensure that

(a) Fuel switch/cock is in “OFF”

position.

(b) Ignition switch is in “OFF”position.

4 Accelerate throttle to “FULL” condition &

then kick several times (6 to 8 times).

5 Note down reading, and repeat the above

process three times and calculate their

average value as actual compression pressure.

6 The specified Compression pressure of engine is 10±2Kg/cm

2

.

STEP- 2

When the compression pressure is below 10Kg/cm

2

then refit the spark plug & start and warm up the

Engine again.

@ Remove spark plug and put few drops of engine oil inside the combustion chamber.

@ Connect Compression gauge & repeat above said procedure as explained in STEP-1.

● If the Compression pressure reading increases, then check for following.

a Worn out cylinder.

b Worn out piston / piston rings.

c Scoring / Seizure of cylinder / piston.

d Piston ring jammed in groove.

● If the Compression pressure does not increase then check for following.

a Incorrect Valve / Tappet clearance.

b Improper torque of cam holder nuts or cylinder head bolts.

c Valve seat damage or Valve leakage.

d Valve is bend.

e Improper Valve Timing.

f Cylinder head warp age.

g Blown out cylinder head gasket.

STEP- 3

• Incase compression pressure is more than 12 Kg/Cm2. Then engine requires Decarbonisation of cylinder

head / (combustion chamber) & piston. Also check for smoky exhaust.

STANDARD DIMENSION OF ENGINE

Loading...

Loading...