Maintenance:General

AM24480,0000349-19-06SEP21-1/1

AM24480,000034A-19-06SEP21-1/1

Usethecorrectoilandlubricant

Toreducetheriskofdamagetothefellinghead,ensure

youusethecorrectoilandlubricant,asindicatedonthe

tablebelow.

Viscosity

Supplier

BrandNamePourPointFlashPoint

220Esso

HeavyChainoil-18°C(0°F)200°C(392°F)

40Esso

HeavyChainoilArctic-48°C(-54°F)145°C(293°F)

120BP

SawchainBarLube

a

-20°C(-4°F)180°C(356°F)

a

Installedbythemanufacturer

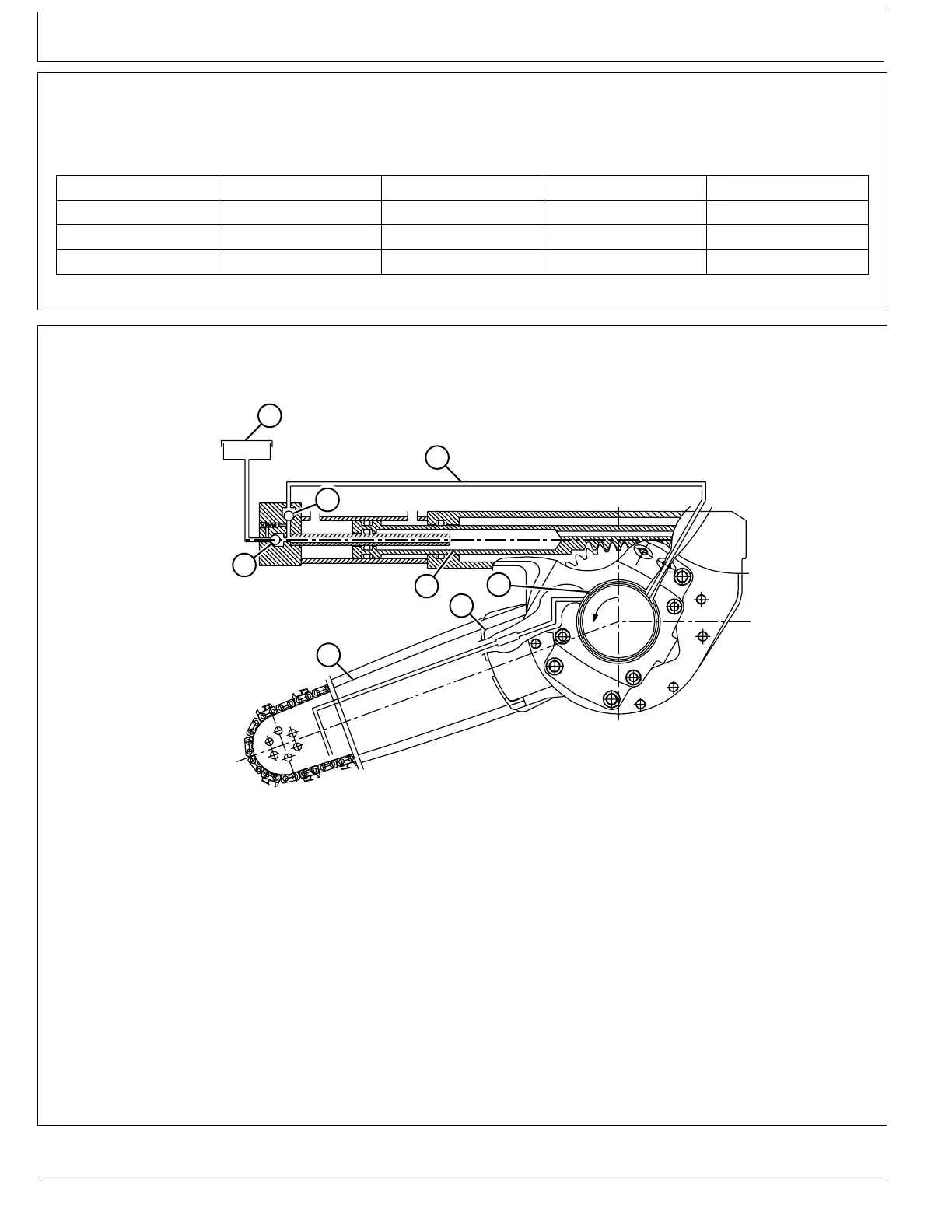

Chainlubricationsystem

TX1044734

3

2

1

7

6

5

4

8

3

2

1

7

6

5

4

8

TX1044734—UN—09JUL08

1—Lubricationoiltank

2—Inletcheck-valve

3—Pistonrod

4—Outletcheck-valve

5—Hydraulichose

6—Sawmotorswivel

7—Barholder

8—Sawbar

1.Thesawunitisequippedwithalubricationoilpump,

whichisintegratedwiththefeed-outcylinder.During

thefeed-outprocess,thelubricationoilpumpsupplies

oiltothesawchainviaapistonoperation.

2.Thelubricationoilpumpisfedwithoilfromtheoil

tank(1),throughtheinletcheck-valve(2),andtoa

reservoirinthepiston-rod(3).

3.Whenthesawbar(8)isfedout,oilgoesthroughthe

outletcheckvalve(4)totheswivelinthesawmotor

(6),viaahydraulichose(5),beforemovingthrough

thebar-holdertothesawbar(8).

4.Oilsupplyisproportional,whichmeansthevolume

ofoilsupplieddependsonhowmuchthesawbaris

fedout.

5.Dependingondifferentlubricationrequirements,the

amountofoilsuppliedtothesawbarcanbevaried,

viadifferentlubricationoilpumps.

3-1-1

090621

PN=41

Loading...

Loading...