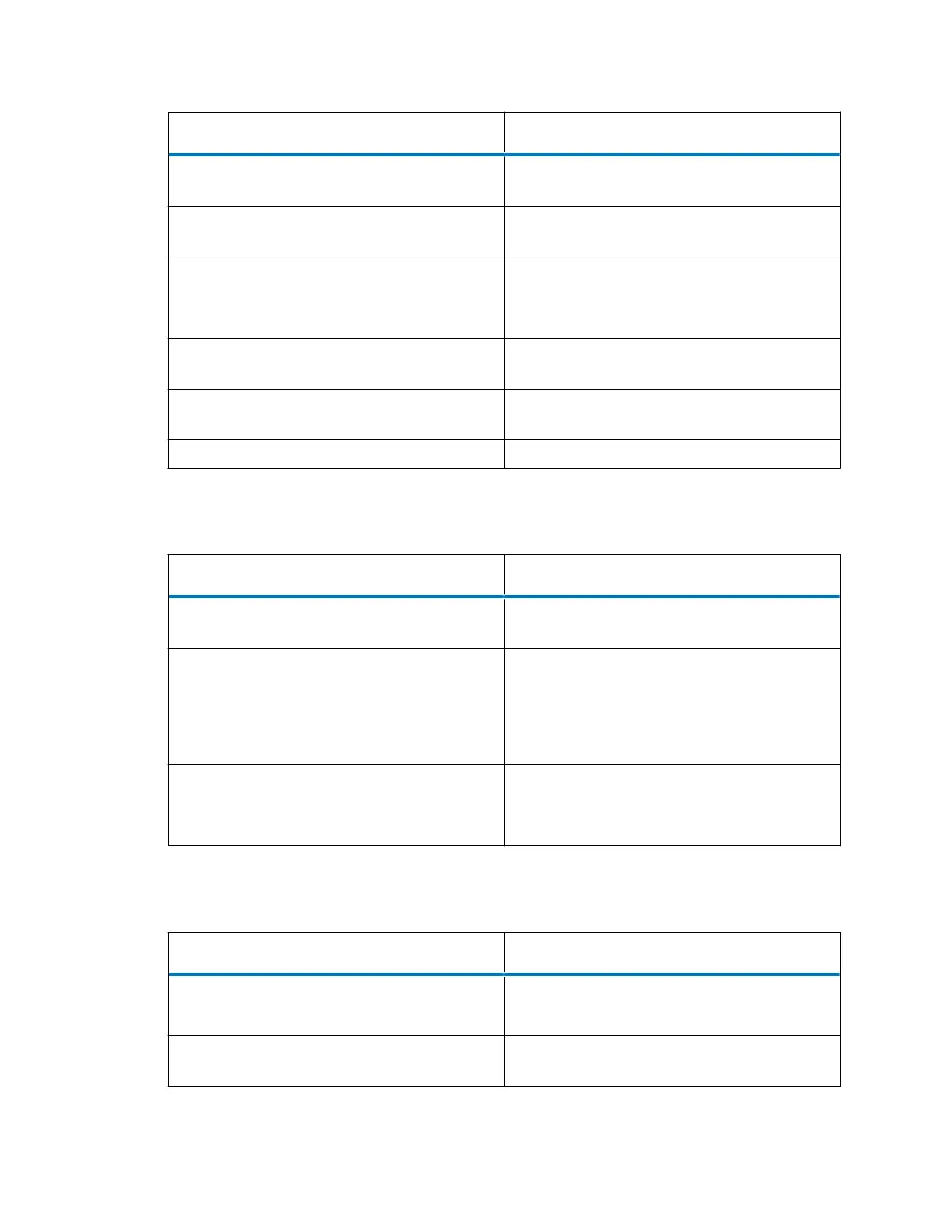

Suspected cause Possible solution

Incorrect diluent makeup Confirm the diluent used for preparing the

sample.

Column conditioning or re-equilibration

problem

Ensure that the column is adequately

conditioned or equilibrated.

Insufficient trapping • Confirm the inlet method parameters.

• Confirm that the trapping column is

trapping peptides efficiently.

Insufficient initial sample preparation Refer to the laboratory sample preparation

protocol.

Interrupted spray See also: The Universal NanoFlow Sprayer

Installation and Maintenance Guide.

Bad trap column Replace the column.

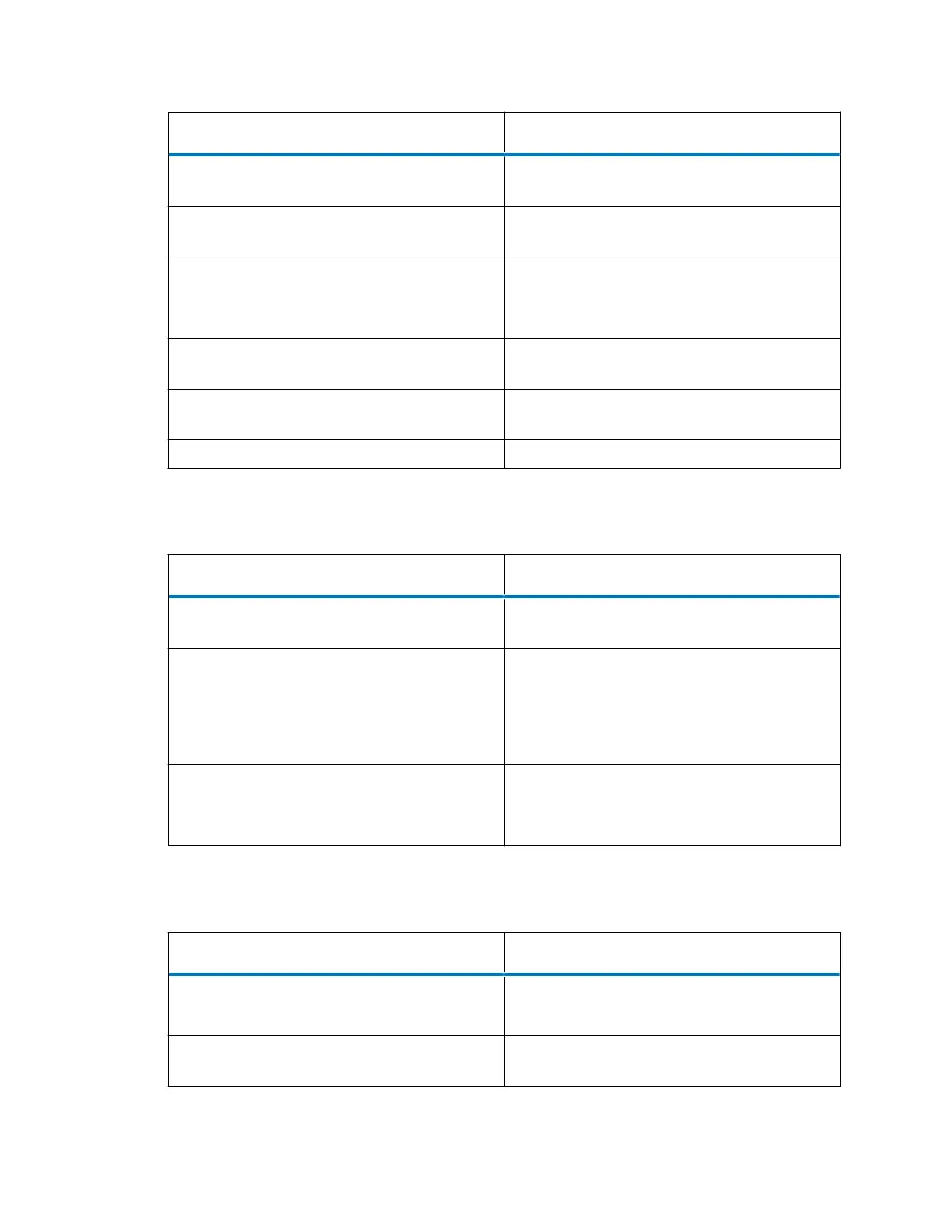

4.3.2.11 Negative peaks

Suspected cause Possible solution

Solvent front at the beginning of the

chromatogram at column void volume

Make the sample diluent similar to the initial

mobile phase.

Signal cables connected improperly (analog

only)

Reset signal polarity, ensuring that you match

positive and negative connections. Refer to the

component overview and maintenance guides

on the documentation CD for specific signal

connection information.

Loss of spray Troubleshoot the loss of spray.

See also: The Universal NanoFlow Sprayer

Installation and Maintenance Guide.

4.3.2.12 Split or double peaks

Suspected cause Possible solution

Injection volume or sample concentration is too

high; disrupting column equilibration.

• Reduce the injection volume.

• Dilute the sample.

Sample diluent is too high in organic for the

initial mobile phase.

Reduce the injection volume or reduce the

percentage of organic in the diluent.

November 26, 2019, 715003588 Revision C

Page 71

Loading...

Loading...