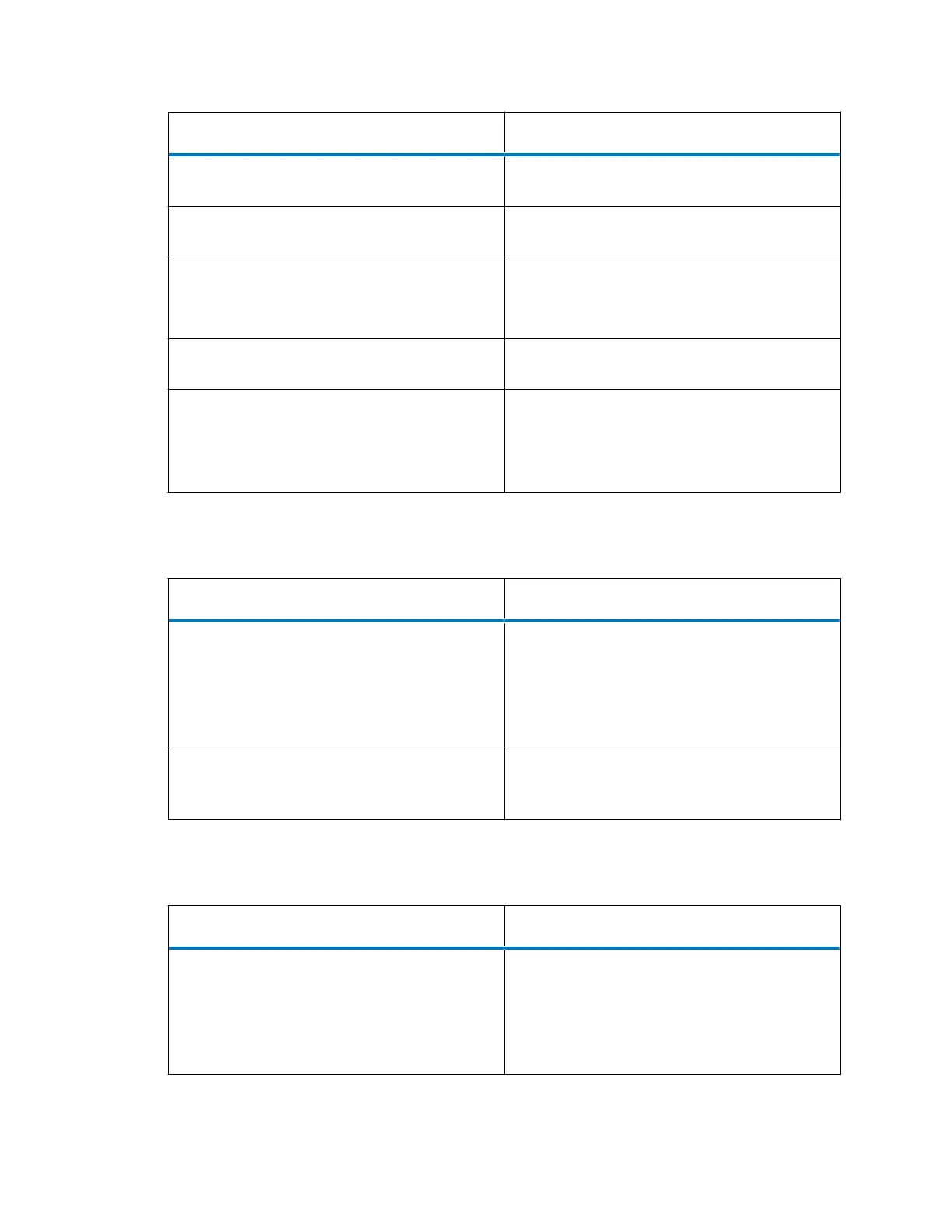

Suspected cause Possible solution

Needle weak wash solvent is too high in

organic.

Ensure that the weak needle wash solution is

similar to the initial mobile phase.

In-line filter, column inlet, or connecting tubing

is partially blocked.

Inspect these components for particle build-up.

Clean or replace.

Column or columns are contaminated. Replace columns.

See also: The appropriate column care and

use guide on the documentation CD.

Column or columns are degraded, forming a

void.

Verify column performance. If efficiency is low,

replace it.

Trap column is degraded. • Remove trap column and perform a direct

injection.

• If results are normal, replace the column

and perform a set pressure diagnostic.

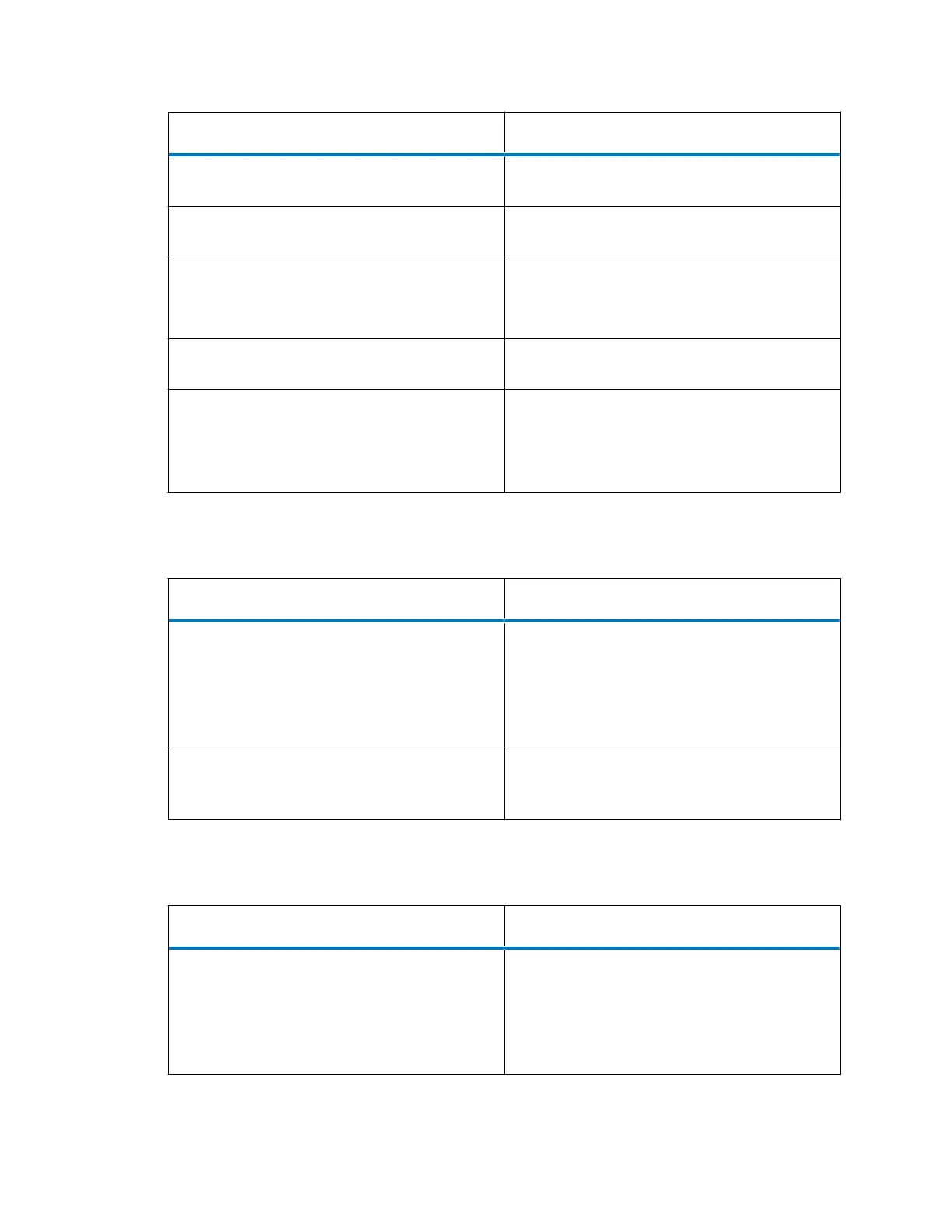

4.3.2.13 Tailing peaks with a normal retention time

Suspected cause Possible solution

Fitting or interconnection problem Inspect sprayer and emitter plumbing

connections.

See also: The Universal NanoFlow Sprayer

Installation and Maintenance Guide on the

documentation CD.

Bad consumables Perform a systematic replacement of

consumables beginning with the analytical

column.

4.3.2.14 Tailing peaks with increased retention time

Suspected cause Possible solution

Leak in the system If the problem persists, perform the set-

pressure diagnostic test to inspect for system

leaks.

See also: The online Help for more

information.

November 26, 2019, 715003588 Revision C

Page 72

Loading...

Loading...