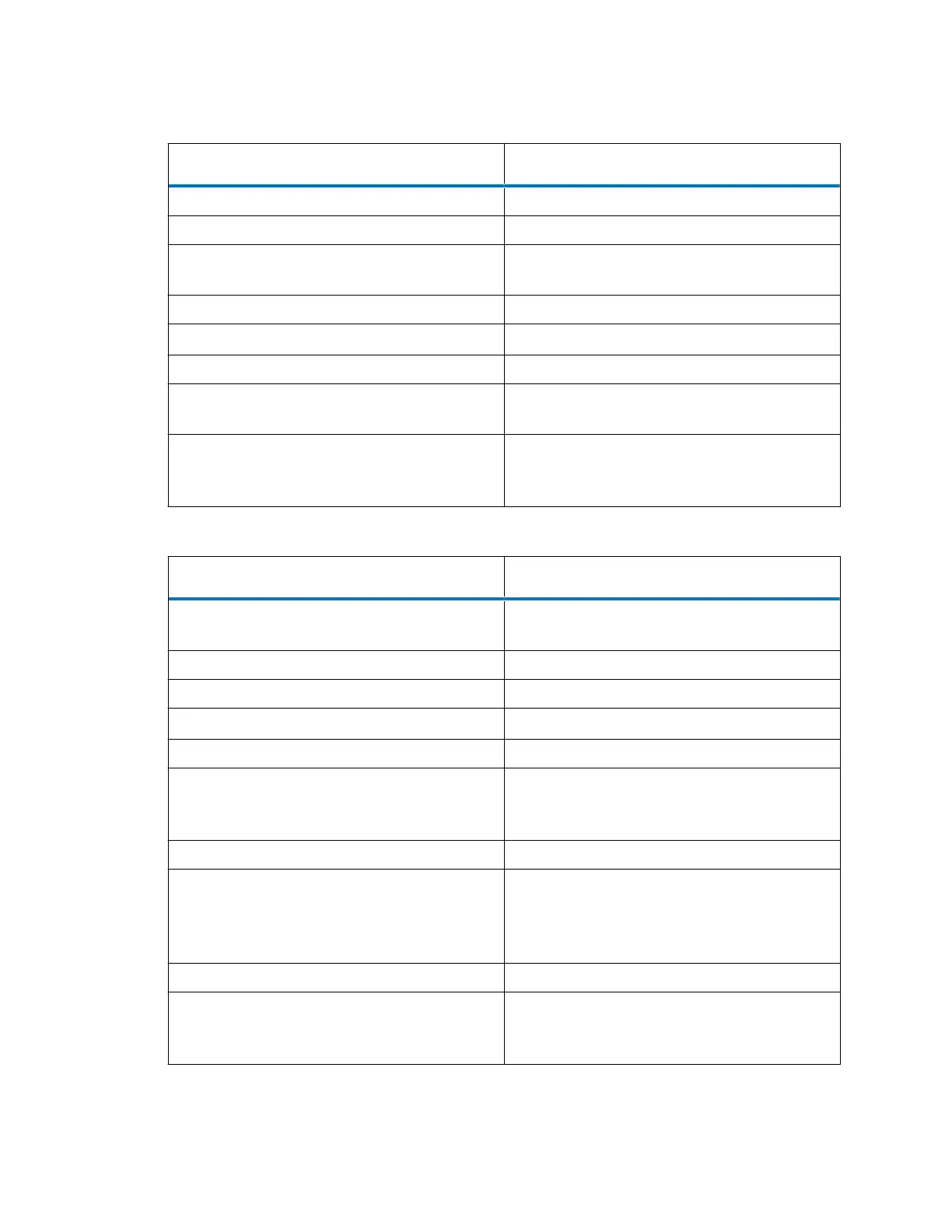

Table B–2: ASM performance specifications

Feature Specification

Column trapping pump (A side) Choice of two eluents

NanoLockSpray addition (B side) Choice of two lockmass solutions

Flow rate range A side: 0.0 mL/min to 1.0 mL/min

B side: 0.0 µL/min to 100.0 µL/min

Solvent conditioning Integrated vacuum degassing, six lines

Primary check valves

Intelligent Intake Valves (i

2

Valve)

Compressibility compensation Automatic, no user intervention required

Priming Automatic, user programmable; wet priming

runs at a flow rate of 4 mL/min

Primary wetted materials UHMWPE blend, MP35N, titanium alloy, gold,

sapphire, ruby, zirconia, DLC, fluoropolymer,

fluoroelastomer, PEEK, PEEK blend, and PPS

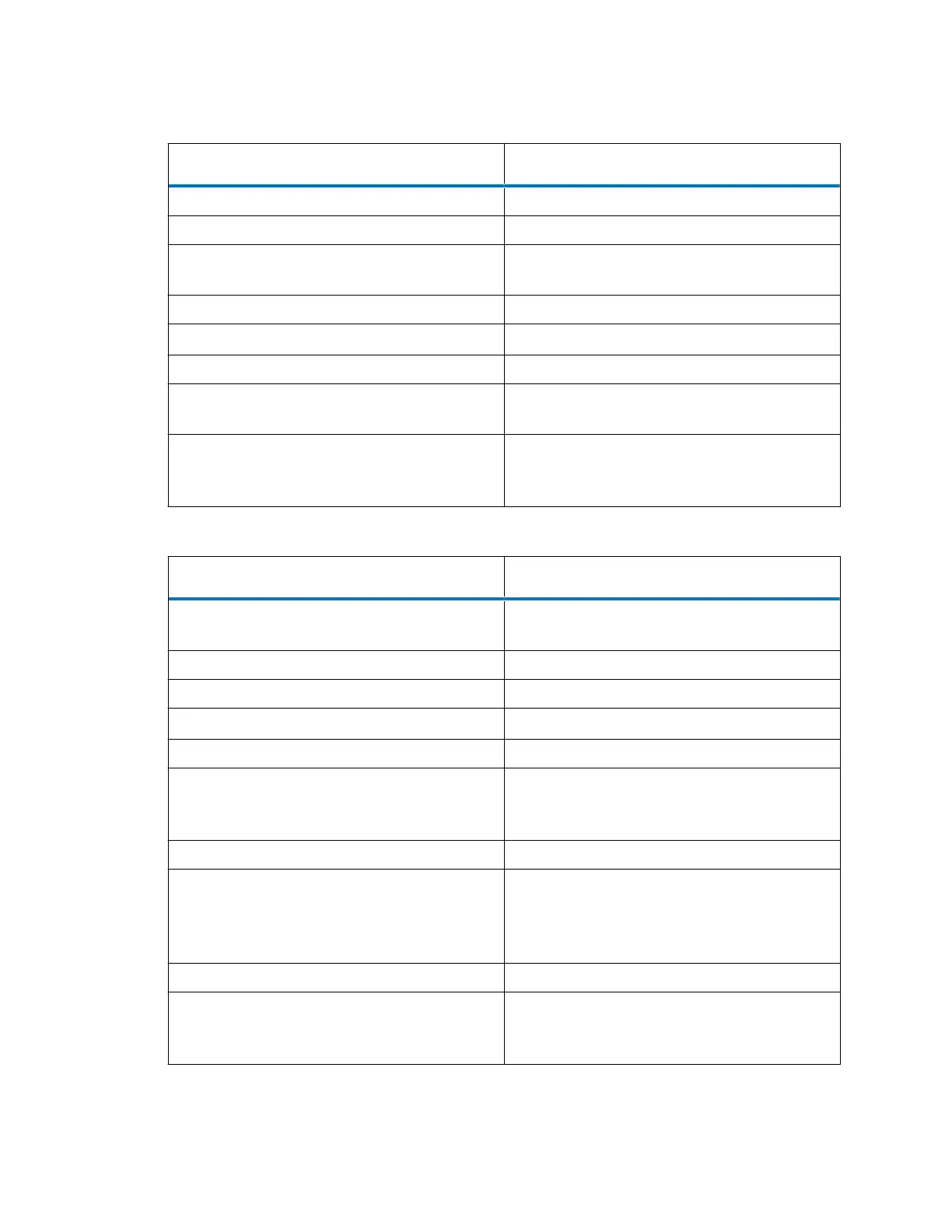

Table B–3: µBSM performance specifications

Feature Specification

Number of solvents Up to four, in combination of two: A1 or A2,

and B1 or B2

Gradient formation High-pressure mixing, binary gradient

Pump compositional precision <0.25 min SD based on six repeat injections

Primary check valves

Intelligent Intake Valves (i

2

Valve)

Compressibility compensation Automatic

Pump seal wash Equipped with an integrated, programmable

active wash system to flush the rear of the

high-pressure seals and the plungers

Flow ramping User selectable from the method editor

Primary wetted materials UHMWPE blend, MP35N, titanium alloy, gold,

sapphire, ruby, zirconia, DLC, fluoropolymer,

fluoroelastomer, PEEK, PEEK blend, PPS, and

fused silica

Mixing options Optional mixer for microscale

Priming Automatic, user programmable; the wet

priming process impels solvent through the

system at a flow rate of 4 mL/min

November 26, 2019, 715003588 Revision C

Page 88

Loading...

Loading...