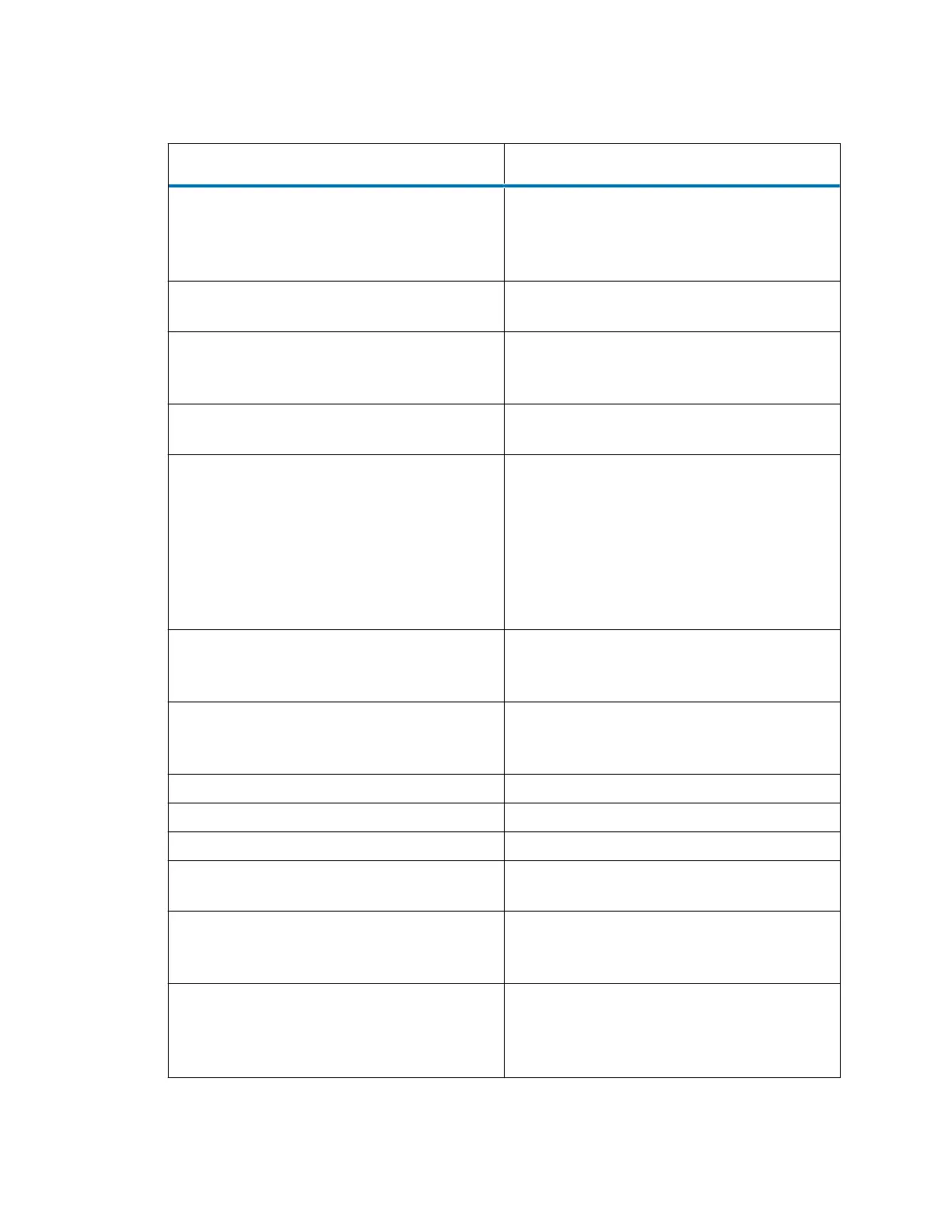

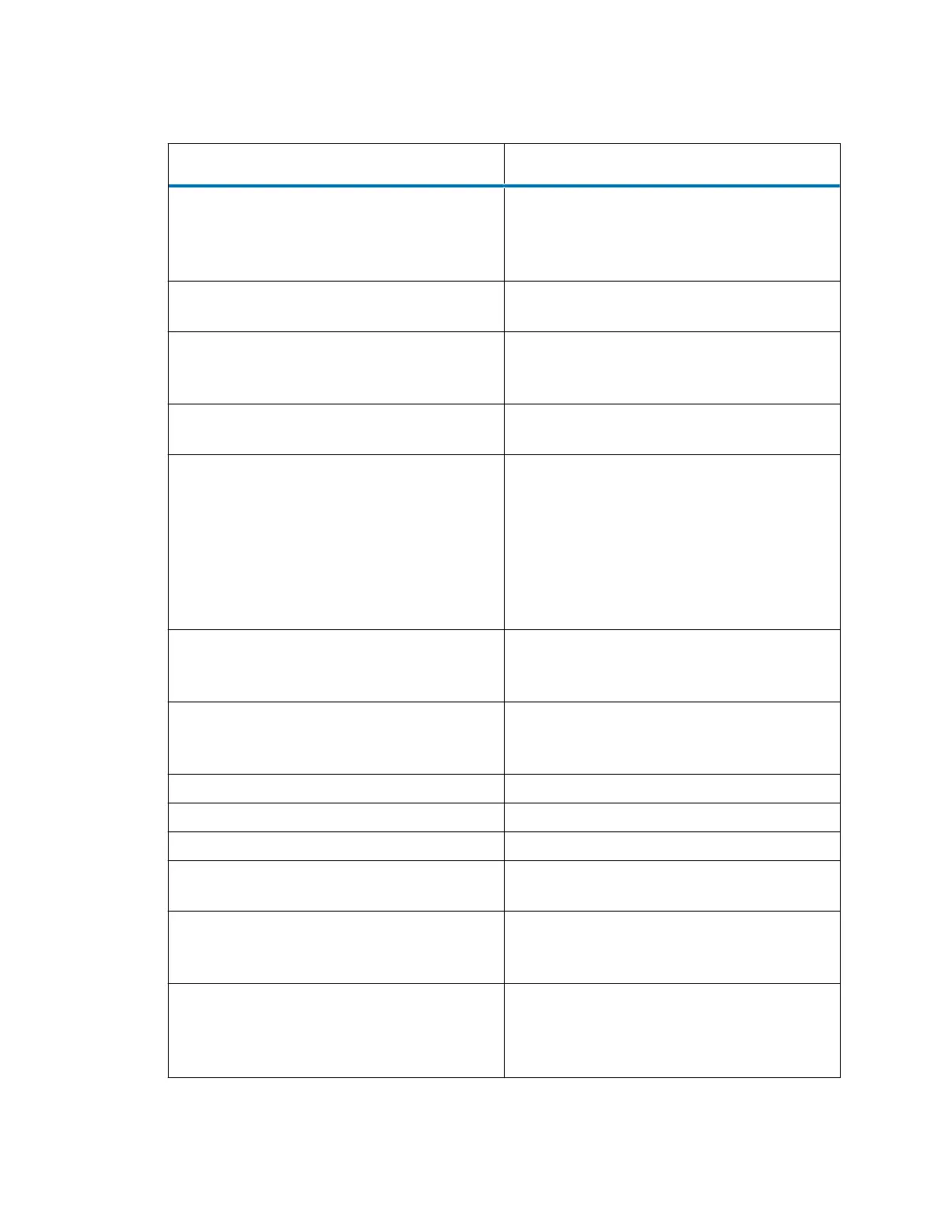

Table B–4: µSM-FL performance specifications

Feature Specification

Injection volume range 0.1 µL to 100.0 µL in 0.1-µL increments; 5-µL

loop standard with 1, 2, 5, 10, 20, 50, and 100-

µL optional loops; unlimited injection volume

during trapping

Injection linearity >0.999 (default needle) from 20% to 80%

volume for the 5-µL loop

Injection modes Full loop mode for optimal quantitation and

dispersion; partial loop mode for fastest cycle

time and sample volume flexibility

Sample manager precision <1% area RSD 0.2 to 1.9-µL injection; <0.5%

area RSD 2.0 to 10.0-µL-injection

Number of sample plates Any two of the following:

• 96- and 384-well microtiter plates

• 48-position 2.00-mL vial plates

• 48-position 0.65-mL micro-centrifuge tube

plates

• 24-position 1.50-mL centrifuge tube plates

Maximum sample capacity 768 in two 384-well plates, or 96 in 2-mL vial

holders, plus four additional positions for

dilution functions or standards

Sample compartment temperature range 4.0 to 40.0 °C, settable in 0.1 °C increments;

maintains 19.0 °C below ambient with a

tolerance range between -2.0 and +4.0 °C

Temperature accuracy ±0.5 °C at sensor

Temperature stability ±1.0 °C at sensor

Injection needle wash Integrated, active, programmable, dual wash

Minimum sample required 3 µL residual, using Waters total recovery vials

(zero offset)

Advanced sample manager capabilities Load Ahead and Loop Offline mode, valve

cycling timed event, multi-load with trapping

independent of sample loop volume

Primary wetted materials Fused silica, DLC, PEEK blend, PEEK,

fluoropolymer, PPS, fluoroelastomer,

borosilicate glass, PPS Blend, 316 stainless

steel

November 26, 2019, 715003588 Revision C

Page 89

Loading...

Loading...