Index-3

I

Flat-topped peaks 3-22

Flow path

1-6

large scale

1-12

small scale

1-12

Flow splitter option

1-14, 2-49

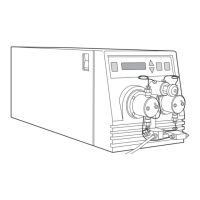

Fluid handling unit

1-5–1-7

Delta-Prep system

1-4

maintenance

3-48–3-67

plunger wash

1-6

Fluid metering

1-6

Fluidic system troubleshooting

3-24

pump leaks

3-25

pump not running

3-24

pump squeak

3-26

Fraction collectors, Waters

1-13

Front panel

1-16–1-19

controller keys

1-18–1-19

display screen

1-16

Fuses

+5 A

3-70–3-71

auxiliary power

3-69

operating voltage

3-67

pump power

3-70

replacing

3-67–3-71

G

Gradient controller 2-15

description

1-22

screen layout

1-23

Gradient table

1-21, 3-44

H

handling symbols A-13

Hardware troubleshooting

3-23

detectors

3-30

fluidic system

3-24

injector

3-26

system

3-23–3-24

Head support, removing

3-57

Help

3-2

online

1-19

High system pressure

3-5

considerations

3-6

Hold Output test

3-41

Hold signal

1-10

HOME key

1-16

I

IEEE-488 address test 3-42

IEEE-488 interface

1-20

cable length

2-17

communication

2-15, 2-17

data system powerup sequence

2-19

Empower cabling

2-15

IEEE-488 address, setting

2-18

PowerLine controller cabling

2-17

shut down sequence

2-19

Waters 845/860 cabling

2-15

Illegal Vial Number message

3-33

Incorrect retention times

3-10

Inject start terminal

1-9

Injector panel

1-12–1-13

connection ports

1-13

purge valve

1-13

Injector troubleshooting

3-26

Rheodyne injector

3-27

needle seal leakage

3-27

plugged valve passages

3-27

Waters autoinjectors

3-27

reproducibility errors

3-28

seal pack leak

3-27

Injectors

Rheodyne 3725i

1-12

Rheodyne 7725i

1-11

Inlet and outlet ports

1-5

Delta-Prep system

1-5

Inlet check valves

disassembly

3-51

Loading...

Loading...