Benchmark with Edge [I]: Operation-Maintenance Manual

SECTION 4 – INITIAL START-UP

OMM-0145_D • GF-218 • 11/2/2020 Technical Support • (800) 526-0288 • Mon-Fri, 8 am - 5 pm EST Page 62 of 213

NATURAL GAS Manual Combustion Calibration Instructions

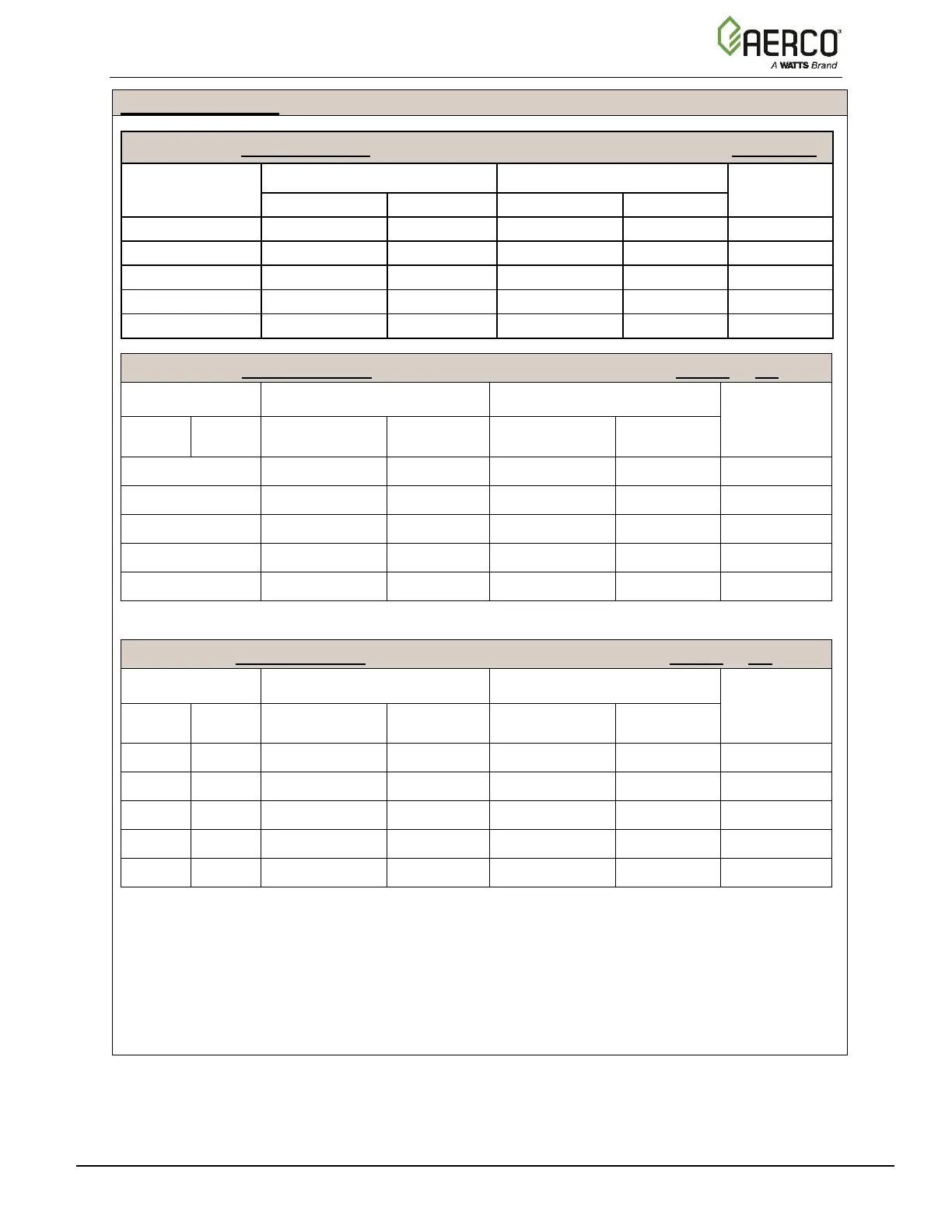

TABLE 4-3g: NATURAL GAS Final Valve Positions: BMK4000/5000N Dual Fuel

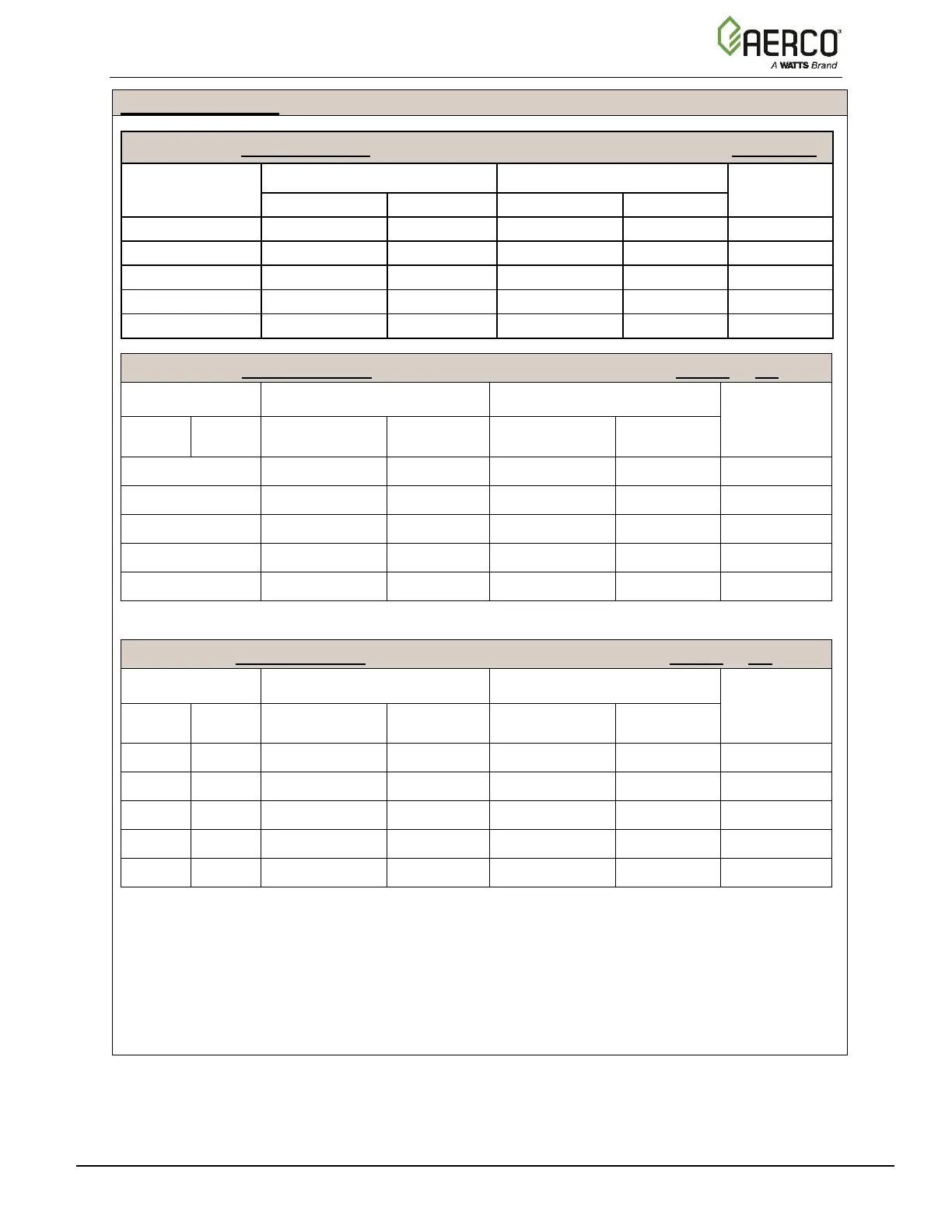

TABLE 4-3h: NATURAL GAS Final Valve Positions: BMK5000, Single & DF

NOTE: BMK5000 Low Gas Pressure (LGP) Model does not offer Ultra Low NOx settings.

TABLE 4-3i: NATURAL GAS Final Valve Positions: BMK6000, Single & DF

Note: BMK6000 Low Gas Pressure (LGP) Model does not offer Ultra Low NOx settings.

26. If the oxygen level at the lowest valve position is too high, and the Blower voltage is at the

minimum value, you can adjust the TAC screw, which is recessed in the top of the Air/Fuel

Valve (see Figure 4-3). Rotate the screw 1/2 turn clockwise (CW) to add fuel and reduce

the O

2

to the specified level. Recalibration MUST be performed again from 60% or 50%

down to the lowest valve position after making a change to the TAC screw.

This completes the NATURAL GAS combustion calibration procedure.

Loading...

Loading...