Operation0820−1/A1

Winterthur Gas & Diesel Ltd.

2/ 7

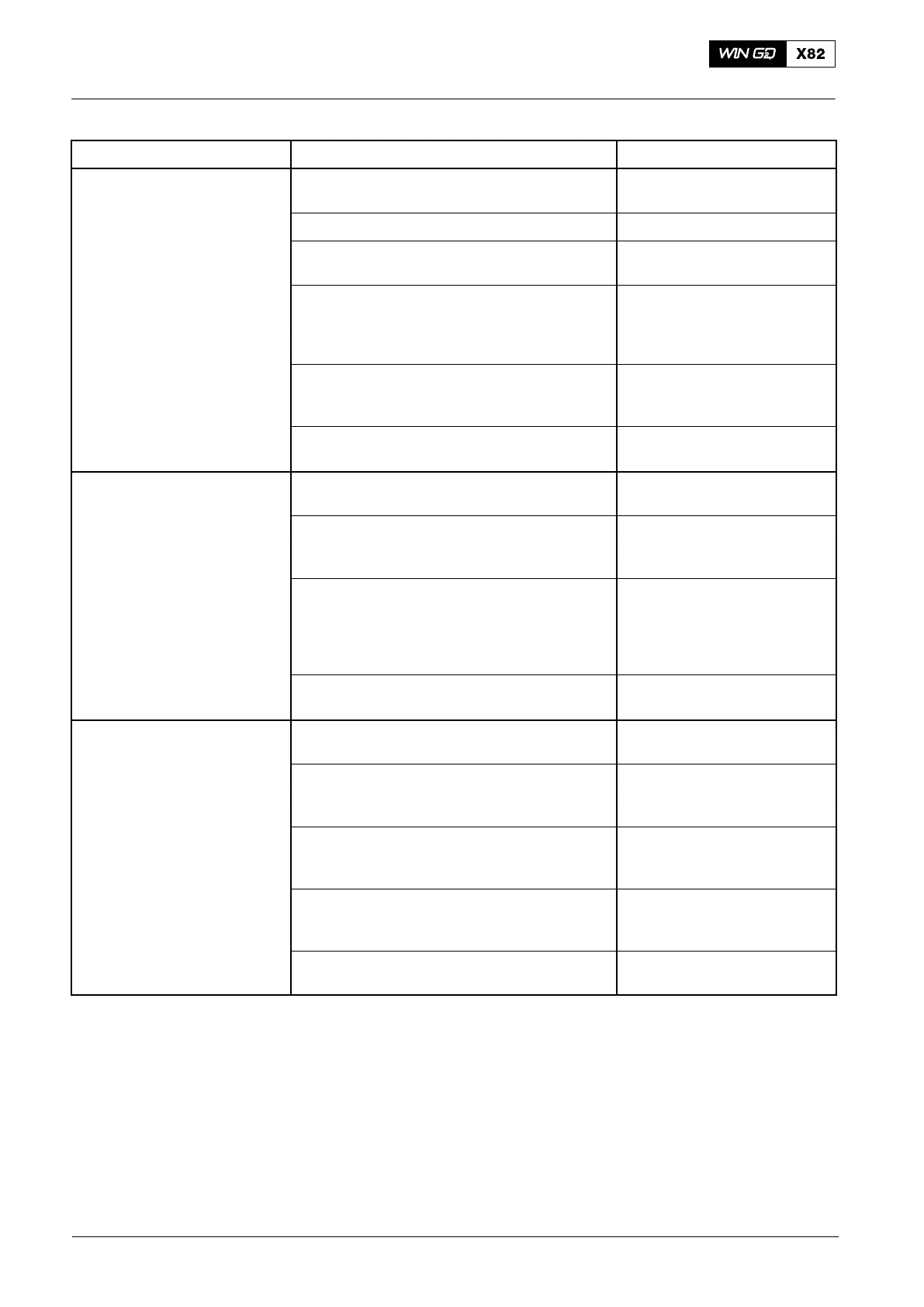

Problem Possible Causes Procedure

The exhaust temperature of a

cylinder increases

The air flaps in the scavenge air receiver are

dirty or defective.

Clean, overhaul or replace

the air flaps.

The injection nozzles are worn. Replace with the spare kit.

The scavenge ports in the cylinder liner are

dirty.

Clean the scavenge ports.

There is a fire in the piston underside space. See 0450−1 Procedures to

Prevent Contamination and

Fire in the Scavenge Air

Spaces.

The exhaust valve has a leak. Grind the valve seat and head

(see the Maintenance

Manual).

The exhaust thermometer of a related

cylinder is defective.

Replace the exhaust

thermometer.

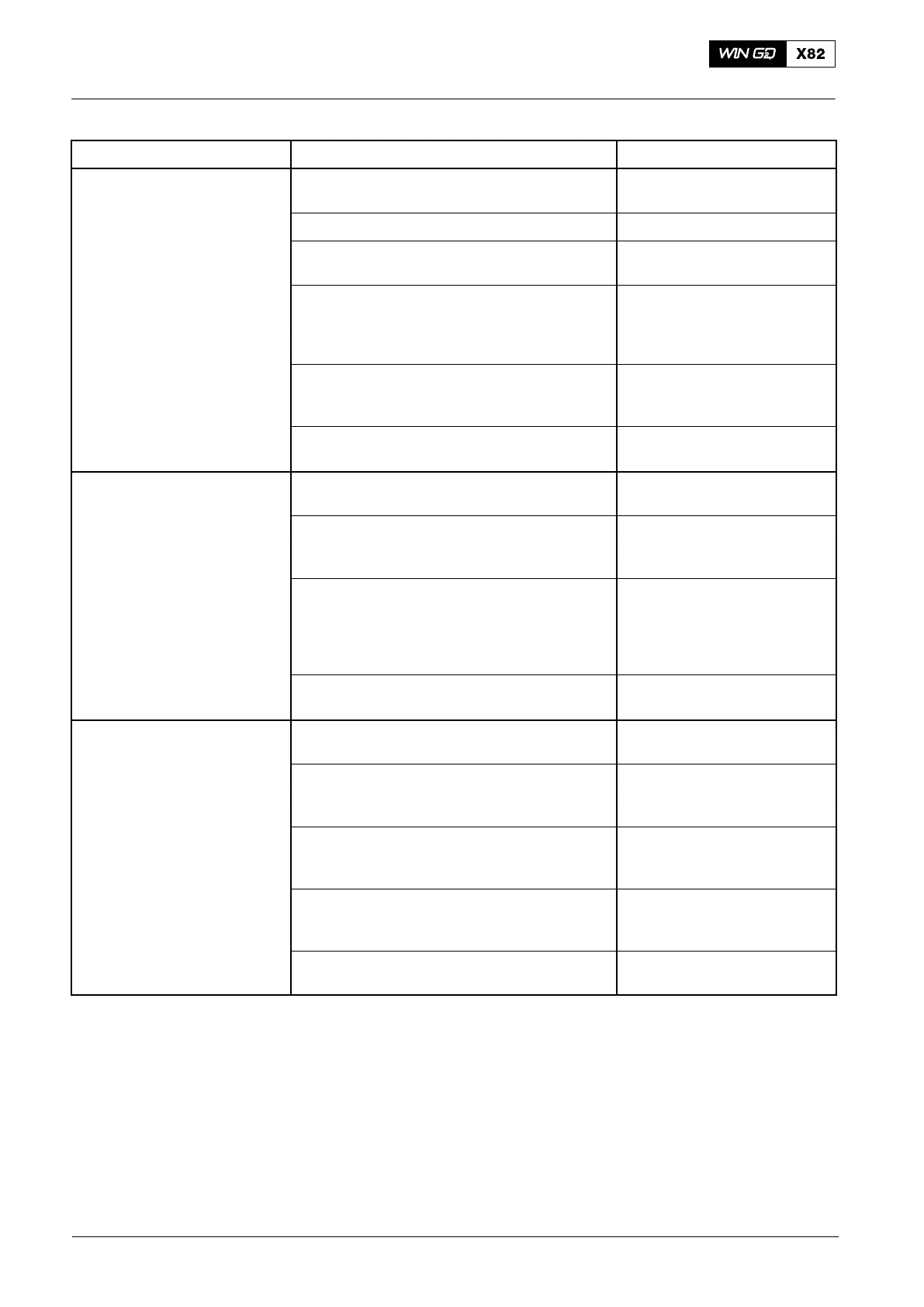

Exhaust temperature of a

cylinder decreases

Injection nozzles are in an unsatisfactory

condition. A nozzle tip is broken.

Replace the nozzle tip.

The related cylinder receives less fuel

because of a leakage in the high pressure

pipes or injection valves.

Grind the sealing faces or

replace defective parts (see

the Maintenance Manual).

The exhaust valve does not open. The

exhaust valve control unit or its hydraulic pipe

is defective.

Cut out the injection and

exhaust valve control unit of

the related cylinder (see

0510−1 paragraph 1 and

0520−1 paragraph 2).

The exhaust thermometer of the related

cylinder is defective.

Replace the exhaust

thermometer.

The engine speed decreases The speed setting from the speed control

system is decreased or not in the limits.

Do a check of the speed

control system.

The fuel injection quantity from the speed

control system decreased to prevent too

much load in heavy sea.

A procedure is not necessary.

Usual operation.

Hull resistance increased because of growth,

age of hull, propeller damage.

See 0070−1 The Relation

between Engine and

Propeller.

An injection valve is defective , an injection

pipe is defective.

Cut out or replace the related

part (see 0510−1 paragraph 1

and 0515−1 paragraph 3.3.2).

The air and exhaust gas pipes are clogged. See Scavenge air pressure

decreases.

2014

Irregular Operation

Loading...

Loading...