Maintenance and disposal TPM

+

en-22 4022-D018396 Revision: 07

Remounting the screw

Loosen the screw.

Remove the glue residue from the threaded bore and the screw.

De-grease the screw.

Coat the screw with a threadlocker (e.g. Loctite

®

243).

Screw in the screw and tighten it with the prescribed tightening torque.

7.1.4 Cleaning

Clean the servo actuator using a clean, lint-free cloth.

If necessary, use a suitable fat dissolving but non-aggressive cleaning agent.

7.2 Startup after maintenance work

Clean the outside of the servo actuator.

Attach all safety devices.

Do a trial run before releasing the servo actuator again for operation.

7.3 Maintenance schedule

7.4 Information on the lubricant used

Make sure that it is possible to remount the screw on the gearhead

without damaging the entire machine.

Pressurized air can damage the servo actuator seals.

Do not use pressurized air to clean the servo actuator.

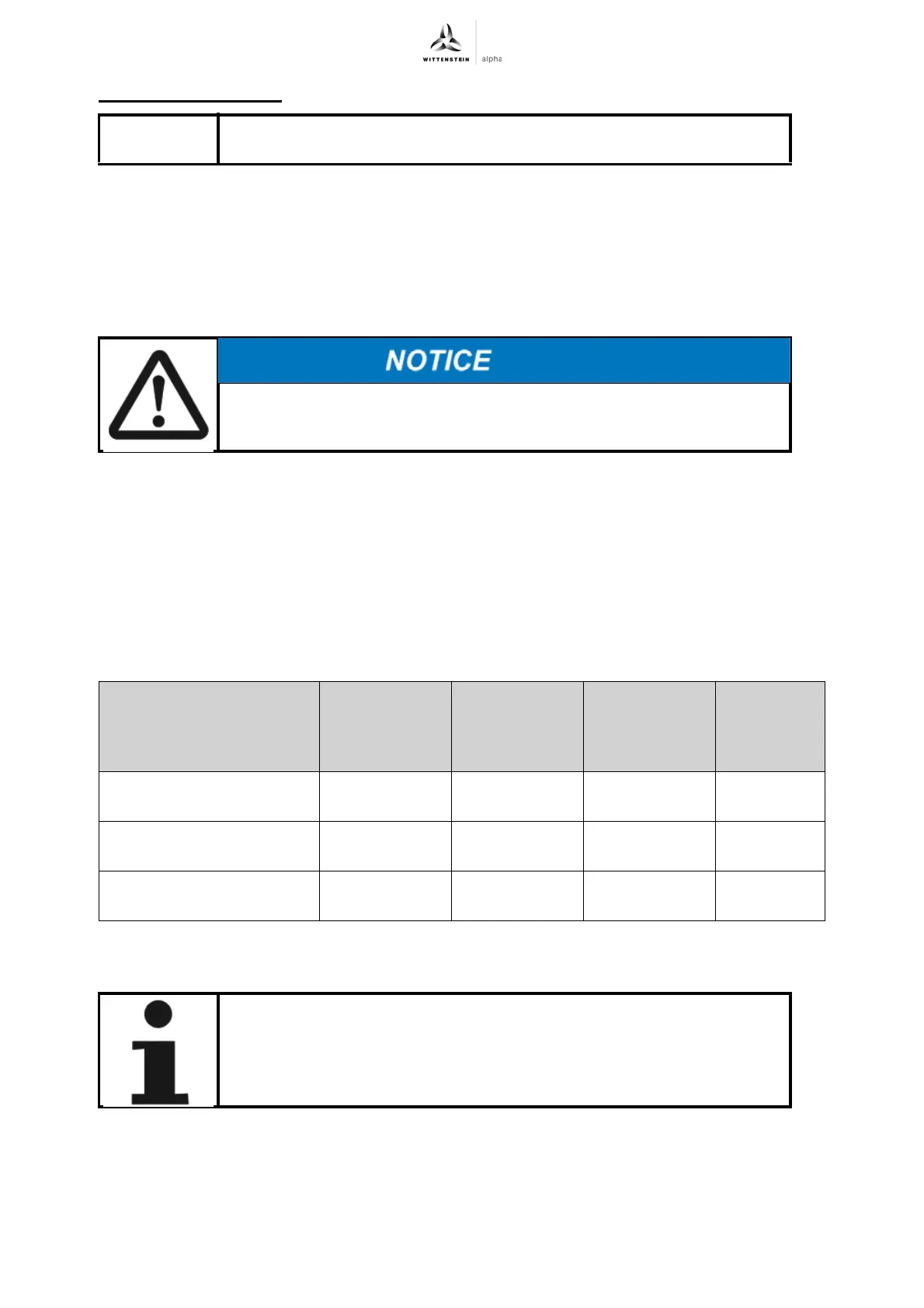

Maintenance work At startup After 500

operating

hours or 3

months

Every 4 weeks Yearly

Refreshment of holding

brake

X

Visual inspection and

cleaning

XX X

Checking the tightening

torques

XX X

Tbl-8: Maintenance schedule

All servo actuators are permanently lubricated by the manufacturer with

synthetic gear oil (polyglycols) of viscosity class ISO VG100, ISO VG220 or

with a high-performance lubricant (see type plate). All bearings are

lubricated for life at the factory.

Loading...

Loading...