Malfunctions TPM

+

en-24 4022-D018396 Revision: 07

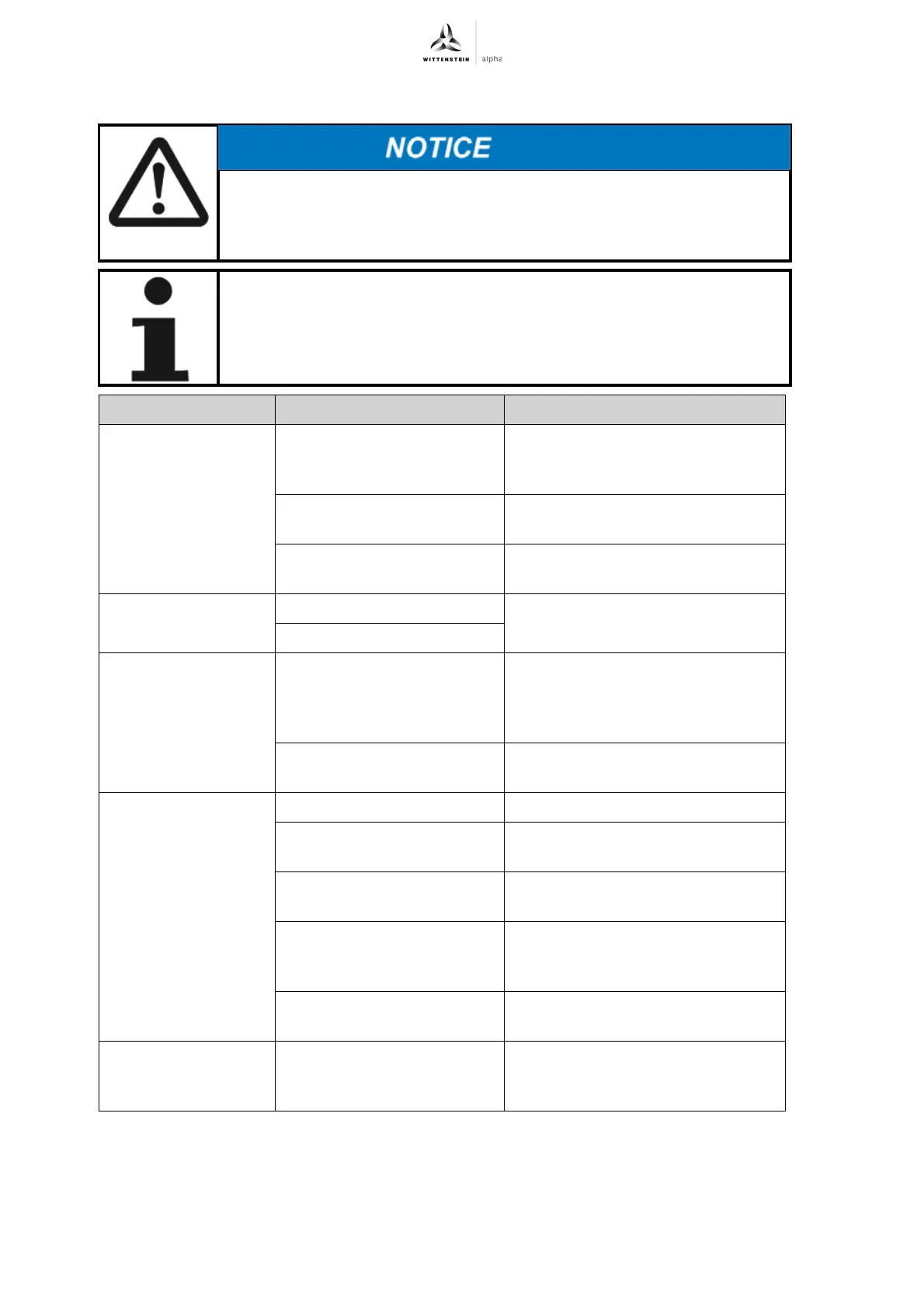

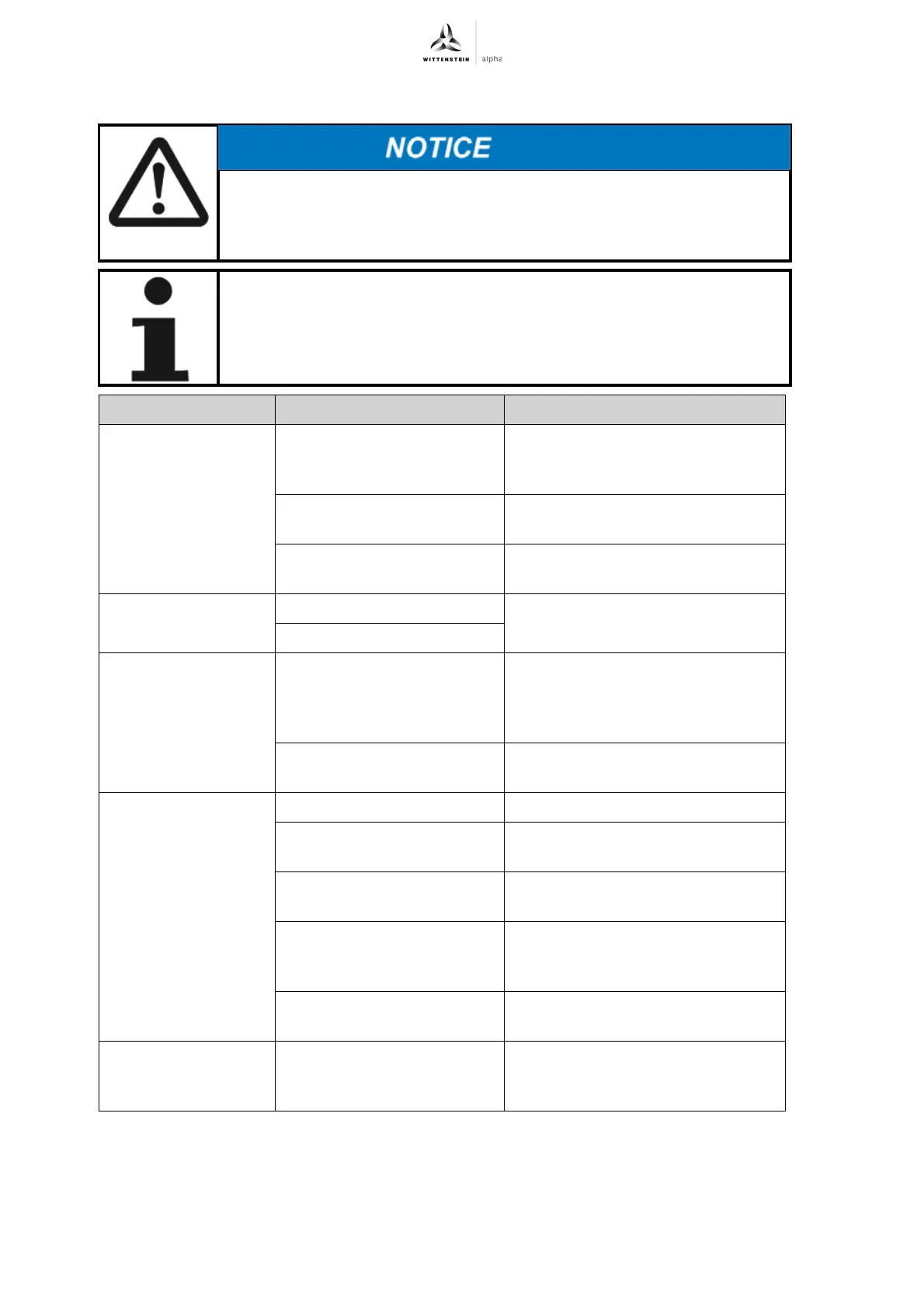

8 Malfunctions

Changed operational behavior can be an indication of existing damage

to the servo actuator, or cause damage to the servo actuator.

Do not put the servo actuator back into operation until the cause of the

malfunction has been rectified.

Rectifying of malfunctions may only be done by specially trained

technicians.

To facilitate troubleshooting and the optimization of controller settings, it is

useful to record the current over a full cycle (a servo controller function) and

make it available as a file.

Fault Possible cause Solution

Increased operating

temperature

Selected construction too

weak for task, nominal

operating exceeded.

Check the technical specifications.

Motor is heating the

gearhead.

Check the controller's settings.

Ambient temperature too

high.

Ensure adequate cooling.

Increased operating

noises

Damaged bearings Consult our Customer Service

department.

Damaged gear teeth

Loss of lubricant Lubricant quantity too high Wipe off discharged lubricant and

continue to watch the gearhead.

Lubricant discharge should stop

after a short time.

Seals not tight Consult our Customer Service

department.

Motor does not start Power supply interrupted Check the connections

Wiring of motor and / or

encoder not correct

Check the wiring of the motor

phases and the motor encoder

Blown fuse Check for errors and replace the

fuse

Incorrect controller

parameters

Check that the motor parameters

are suitable for the implemented

servo actuator

Motor protection has been

triggered

Check for errors. Check whether the

motor protection setting is correct.

Wrong direction of

rotation

Wrong set value

specification for the servo

controller

Check servo controller/converter.

Check the set value specifications

and the polarities

Loading...

Loading...