Align the Head When Motors are Disengaged

Align the Head

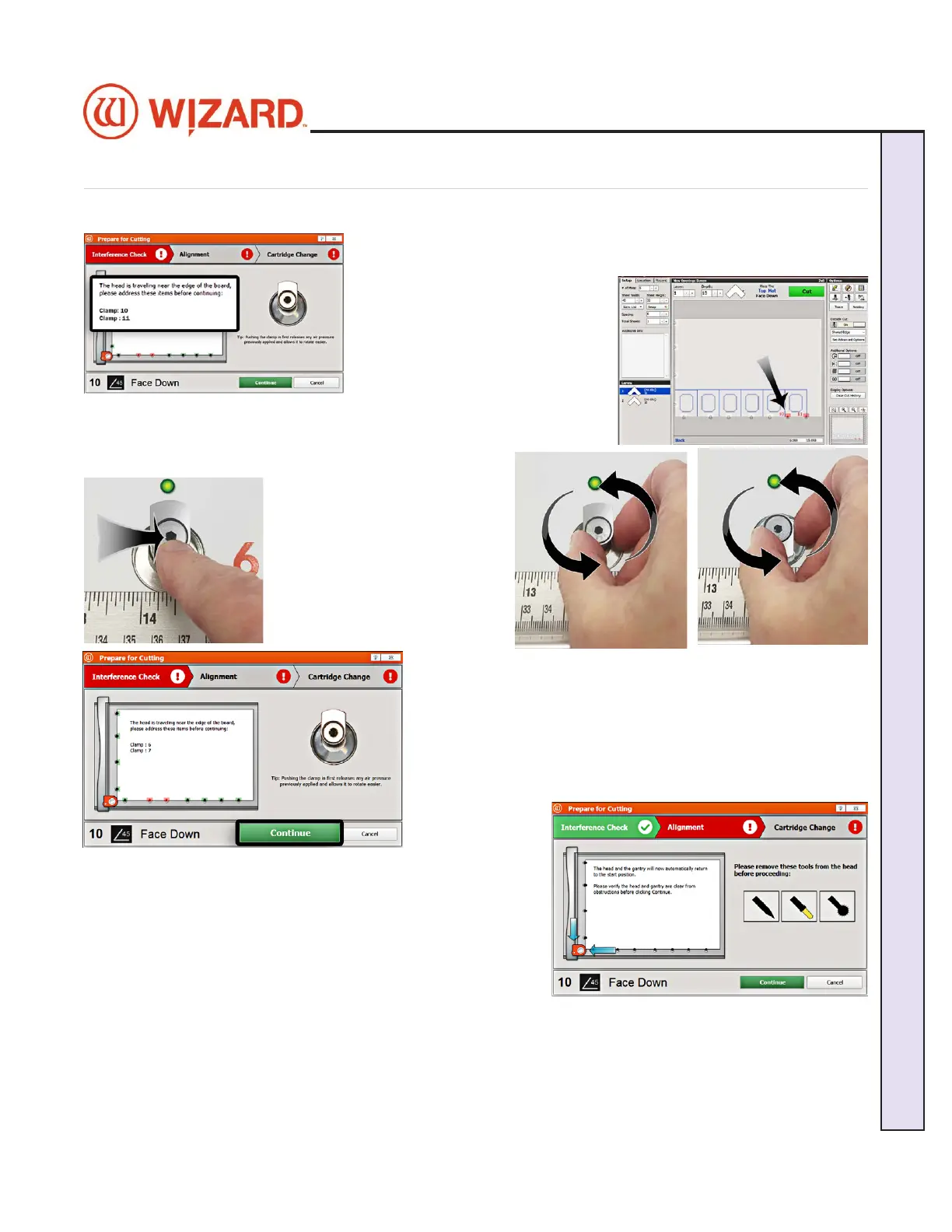

1. The CMC will do an interference check to see if any of the nger-

clamps are in the way of the current cut sequence.

2. If any of the nger-clamps are in

the way, the light above the specic

nger-clamp on the board will ash

red and the Cut Preview screen will

highlight in red which nger-clamp

number needs to be rotated out of

the way before you cut the mat. See

“Head LED Behavior” page 29 and “LED Clamp Behavior” page

30 for information on the LED head and clamp indicators.

3. To rotate the nger clamp out of the way, push the

indicated clamp toward the board

to release the pressure.

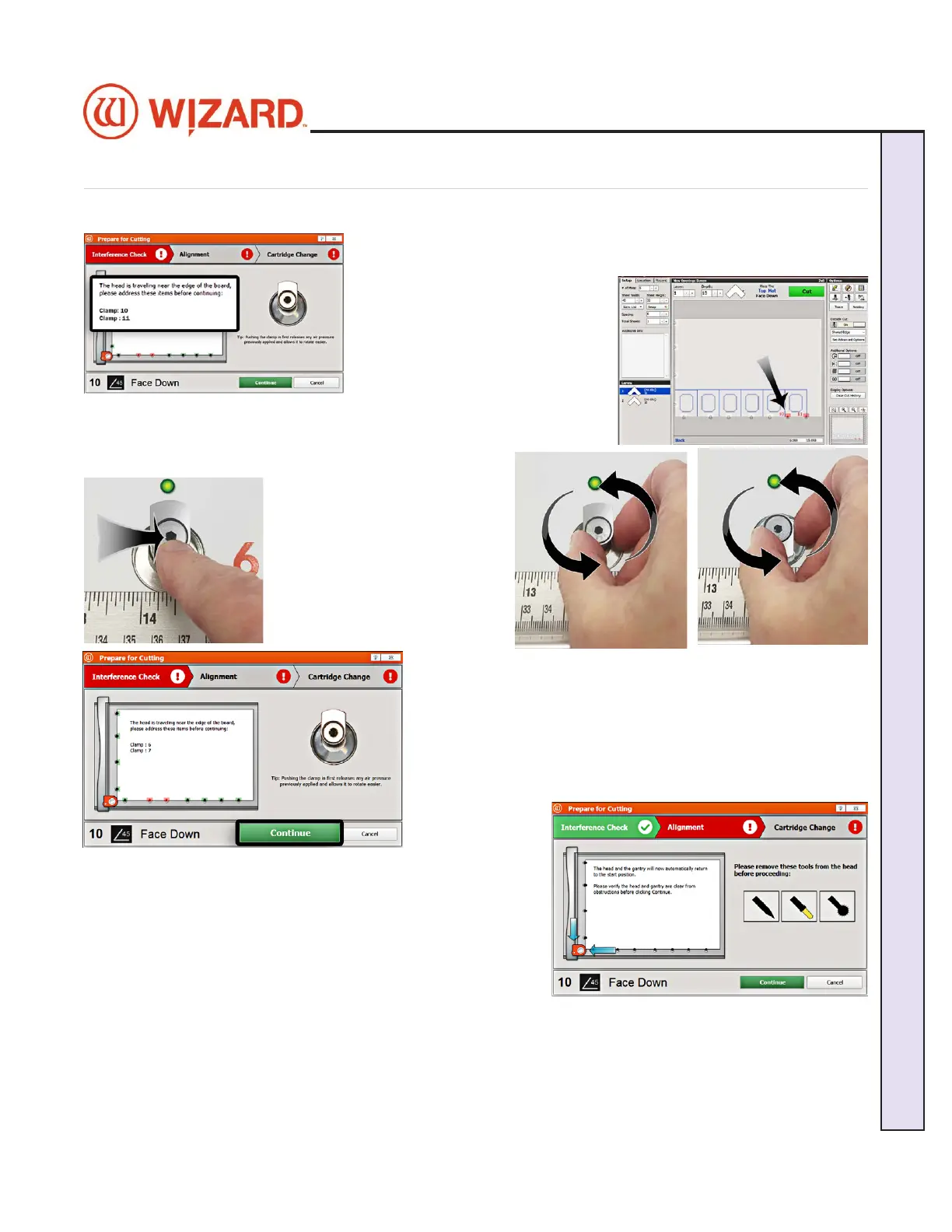

4. Rotate the indicated clamps

so that they are facing away from

the center of the board.

5. When the clamps are

engaged, they will be retracted

ush with the board.

6. For the

next cutting job, the clamps should be rotated back toward the

center of the board to hold down the next mat.

7. Click Continue on the Interference screen. It will perform

the interference check again to make sure that all of the nger-

clamps have been correctly rotated.

8. If it passes the interference check, it will continue to the

Alignment

screen.

9. Make sure that the Pen, Vinyl and Crease tools are not in

the foot block. It will then align the head as described below.

10. After aligning the head, it will immediately proceed to the

Cartridge Change screen.

20-36070-1 GettingStartedManualZ1FrameShop

04/07/21

21

Wizard CMC Model Z1 Hardware and Software Getting Started Manual

Wizard™ CMC Model Z1 Hardware and Software Getting Started Guide

Loading...

Loading...