Maintenance

Steel Guide Blocks

5

5-3 60HDdoc081208 Maintenance

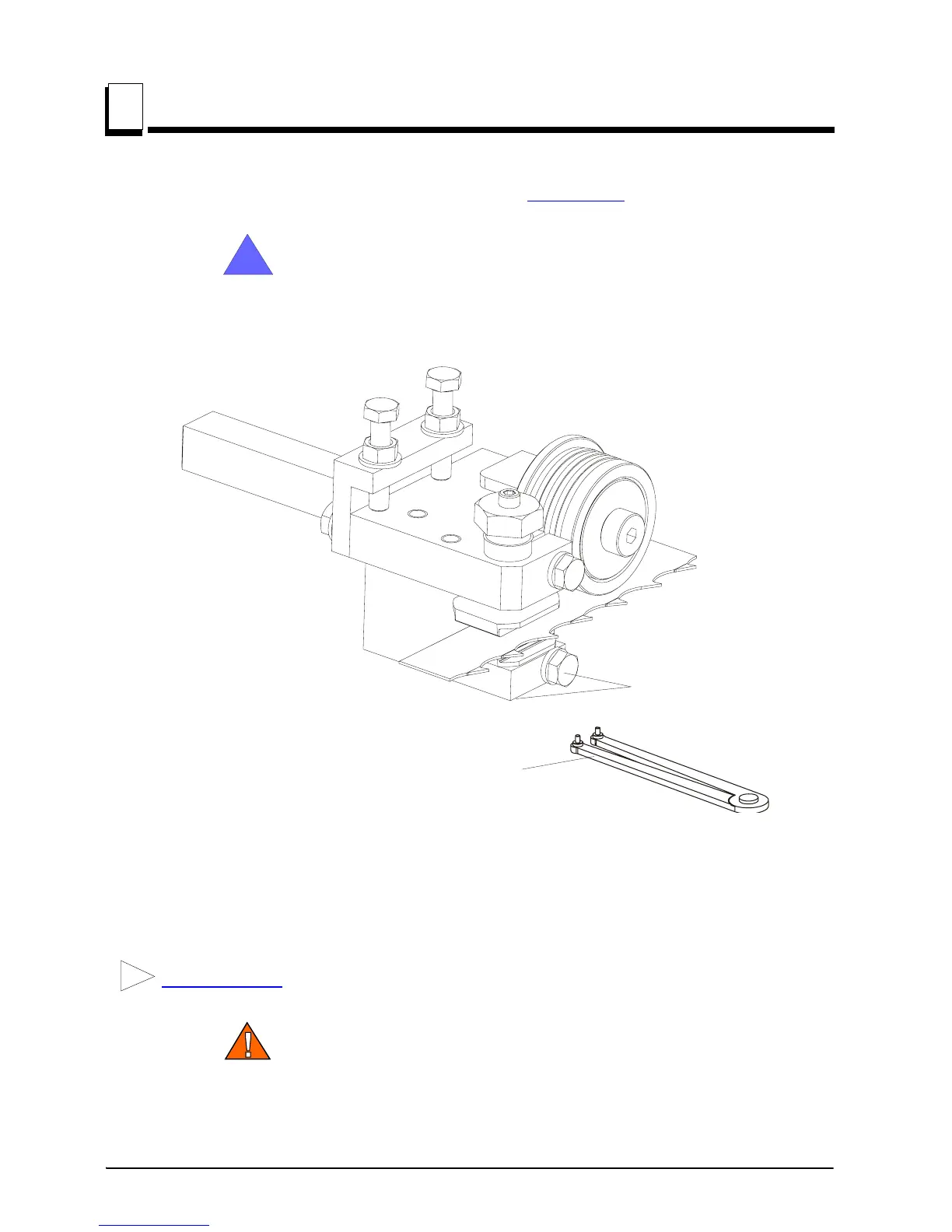

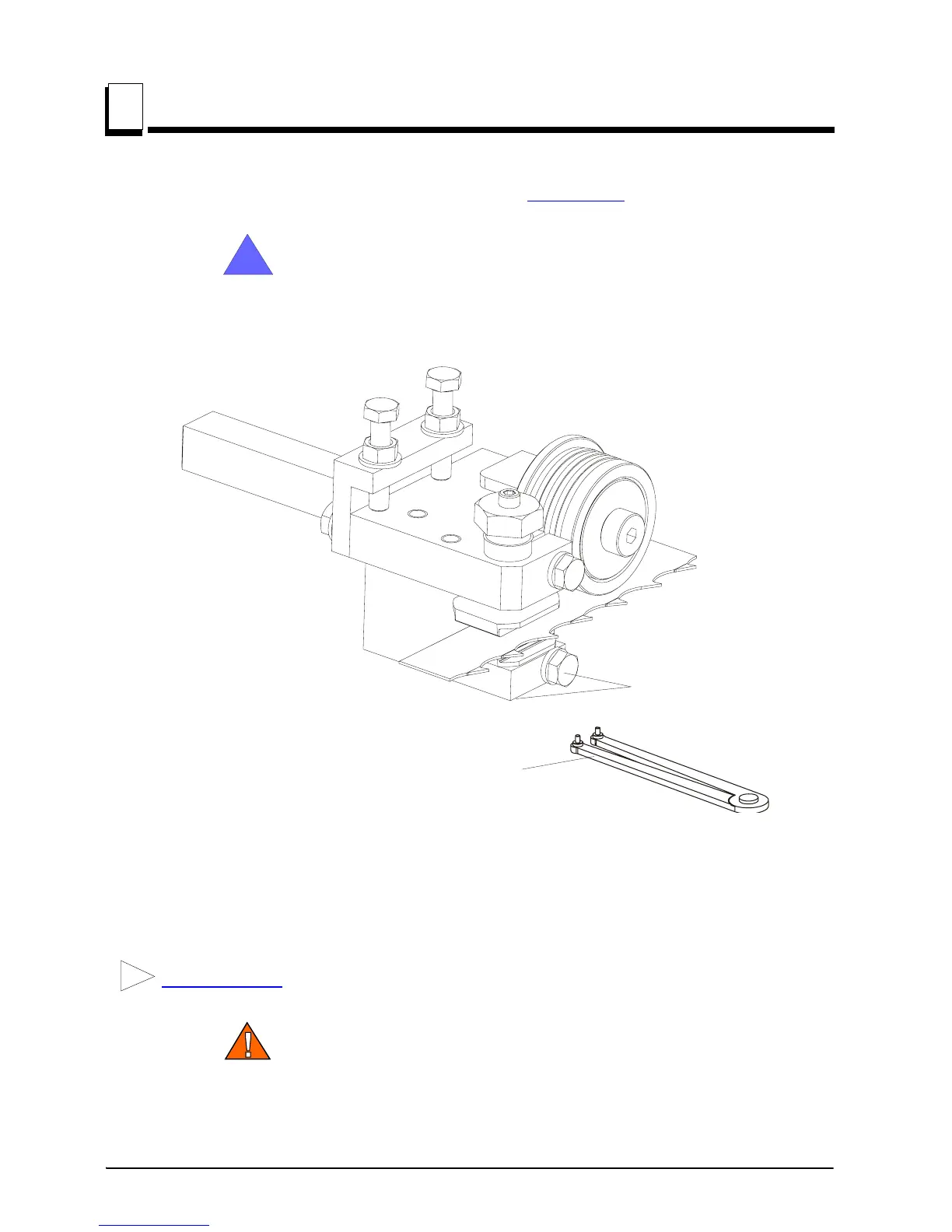

clamp bolt. Use the provided adjustment tool. to raise bottom disk Retighten the bottom

disk mounting bolt and clamp bolt.See Section: “See Section

”

IMPORTANT! The ceramic inserts should be parallel to the

blade. Check the space between the insert and the blade at

each side of the insert to insure it is parallel. Use the appro-

priate outer adjustment bolt to tilt the insert mounting plate

so the insert is parallel to the blade.

After adjusting the drive side blade guide block insert up, check the deflector. If neces-

sary, loosen the two deflector mounting screws and adjust the deflector so it does not

touch the blade.

Inspect the blade guide assemblies for proper alignment everytime you change the blade.

See Section 8.1

for blade guide adjustment instructions.

WARNING! Blade guide alignment is essential for optimal

cutting performance, blade life and safety. Failure to check

and maintain proper blade guide alignment will result in

stress cracks forming in the blade. These cracks will lead

to premature blade breakage. If the blade breaks during

operation and the blade has multiple stress cracks, the

FIG. 5-1

!

Loosen

mounting

bolt and

clamp bolt

Use bottom disk

adjustment tool to

raise bottom disk

A/R

Loading...

Loading...