Maintenance

Blade Guides

Maintenance 60HDdoc081208 5-2

5

5.2 Blade Guides

1. Check the rollers for performance and wear every blade change. Make sure the rollers

are clean and spinning freely. If not, rebuild them. Replace any rollers which have worn

smooth or have become cone shaped.

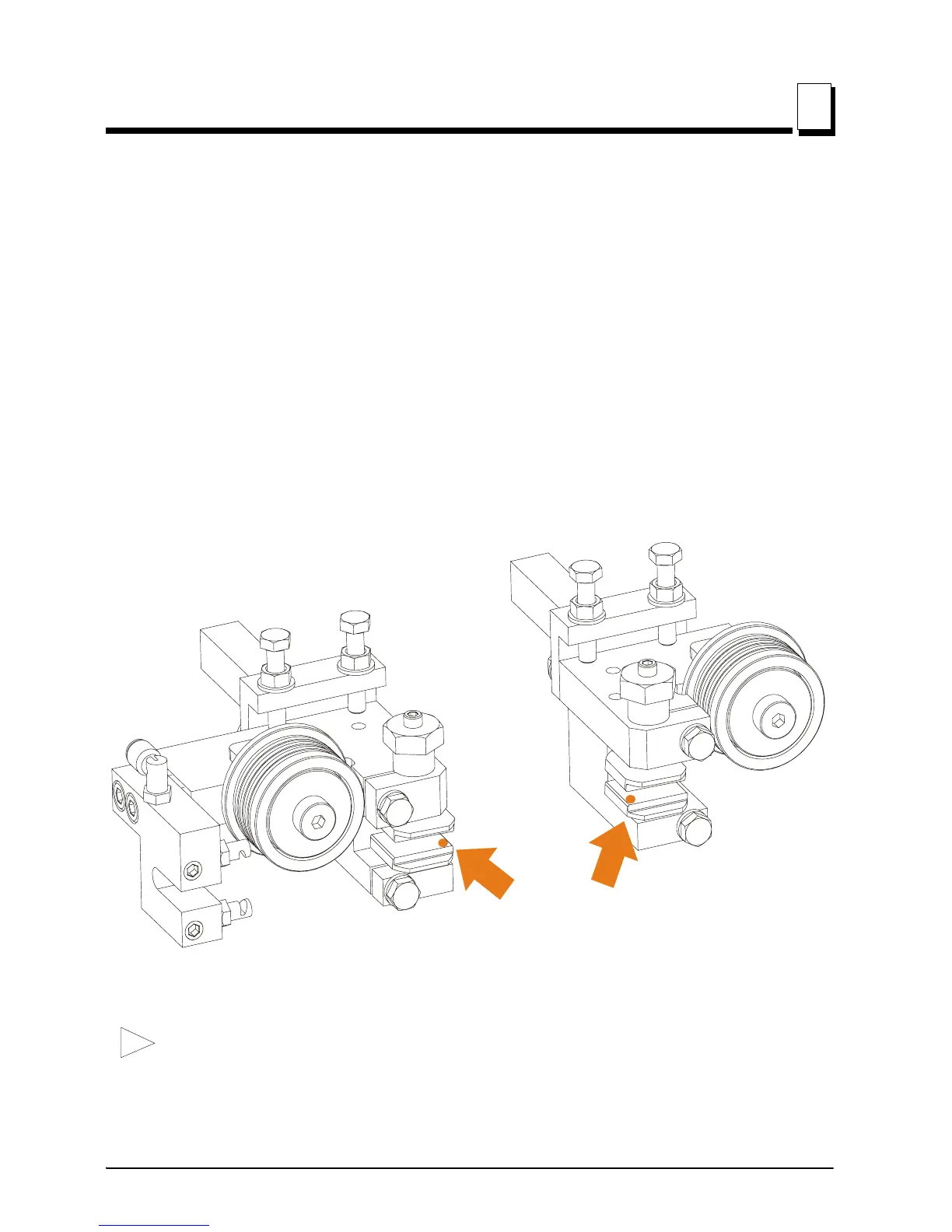

Steel Guide Blocks

2. Inspect the blocks at every blade change for damage or wear.

As the blocks wear, the front inside corner will wear more than the body of the block.

When the corner wears far enough, sawing performance will be affected even if the body

of the block is adjusted properly to the blade. At this point, the block should be replaced.

If you have access to the appropriate equipment, you can grind or mill the blocks to a new

flat surface and reuse them. It is recommended you develop a routine schedule for

replacing the blade guide blocks based on your sawing conditions and experience.

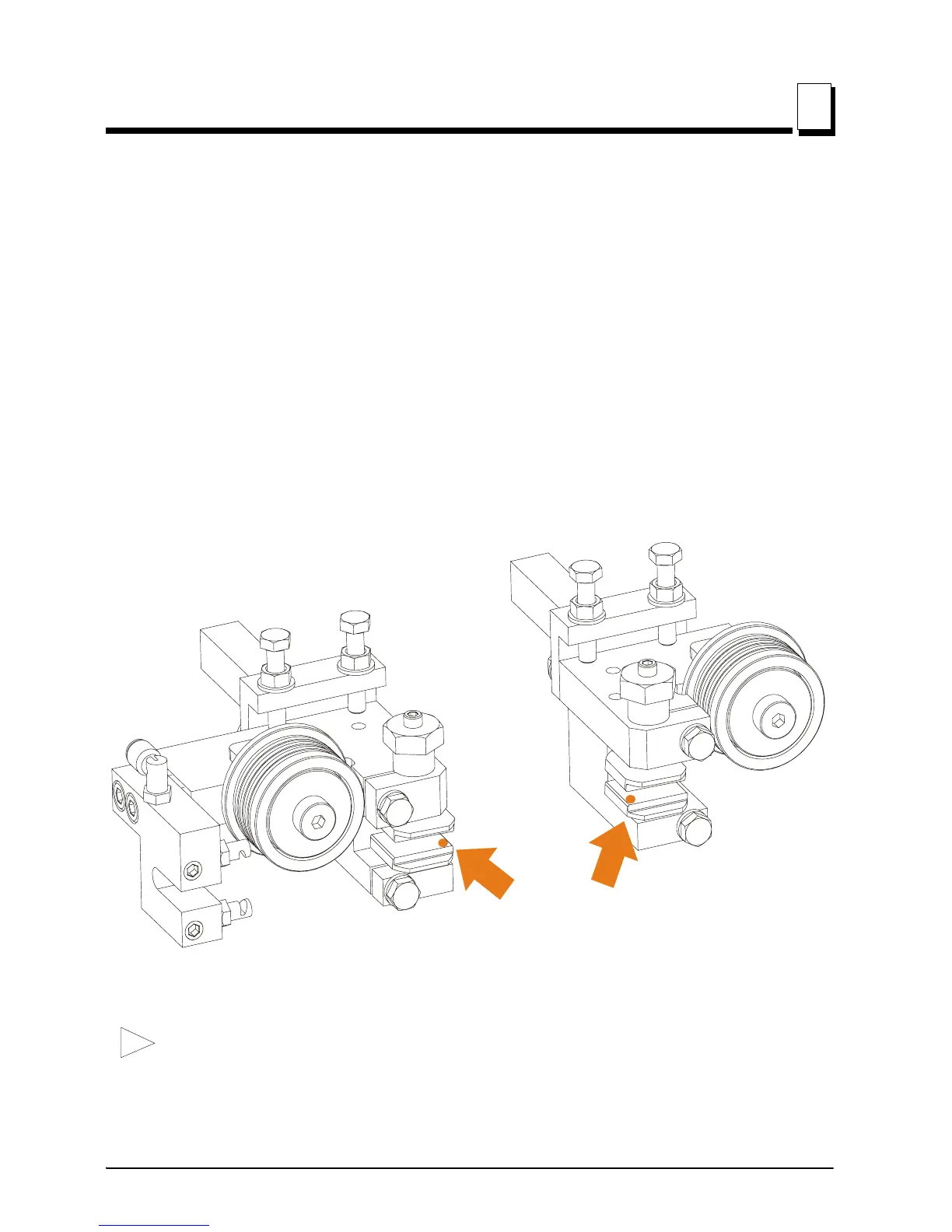

3. Check the ceramic inserts are properly spaced from the bottom of the blade every 25

hours of operation. As the rollers wear, the gap between the blade and inserts will

become larger. Use the provided shim or a feeler gauge to check the inserts are adjusted

0,2 - 0,25 mm from the blade.

See Figure 5-1. To adjust the disks up, loosen the bottom guide disk mounting bolt and

RYS. 5-0

25

Loading...

Loading...