Page | 25

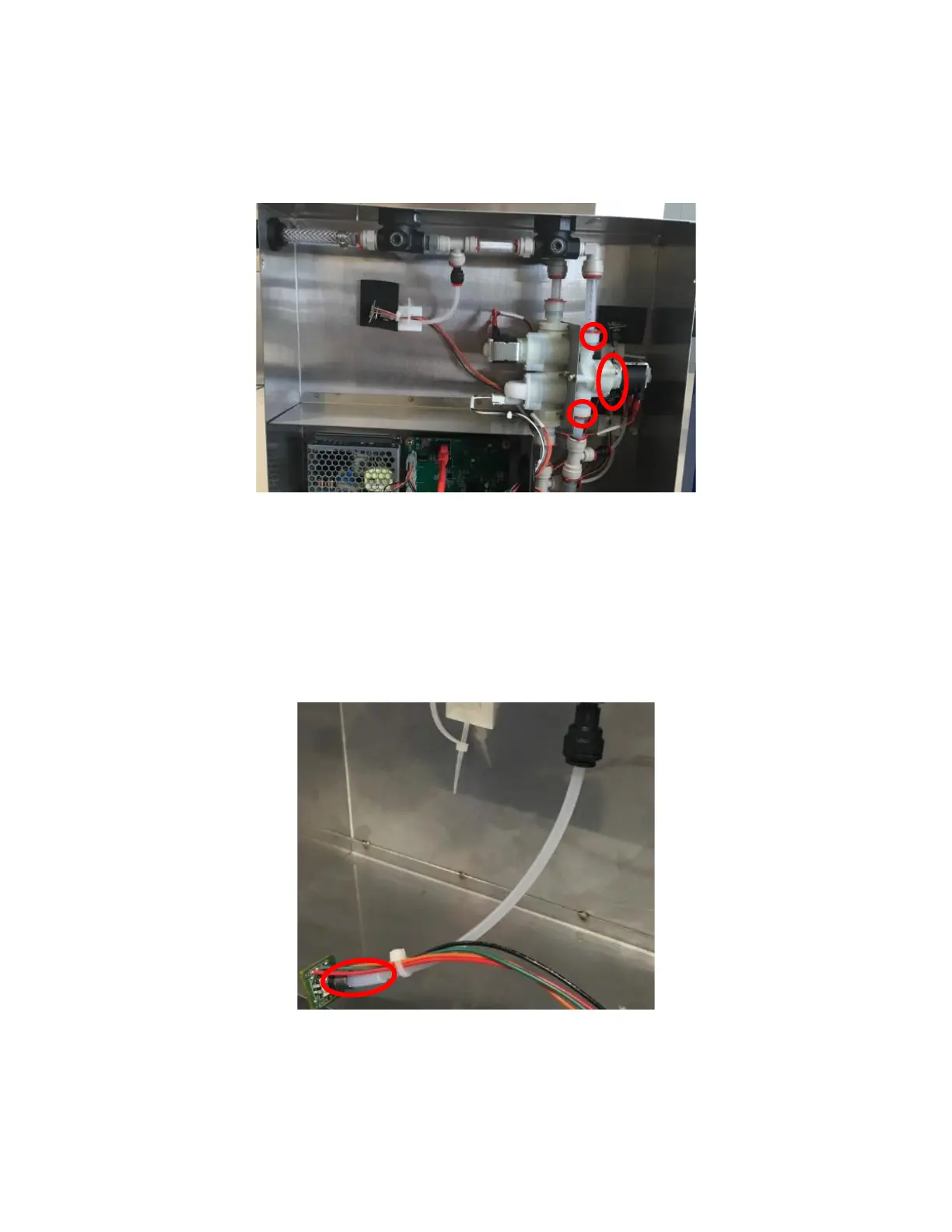

ii. If leak is suspected from Solenoid (Nitrogen Line), apply Soap Water Solution to the Solenoid in locations

circled in Figure 49. Open both regulators fully and inspect for bubble formation to detect leak. If leak is

coming from push to fit locations, first attempt to push the tubes further into the joint; if pushing the

tubing in further is unsuccessful in stopping the leak, replace the Solenoid. Refer to Appendix H: Nitrogen

Line Solenoid Replacement for procedure. Wipe all connections checked with Soap Water once test is

complete.

iii. Check all push to connect fittings with soap solution. If leak is found, try pushing the tube connected to the

push to connect fitting further in. If the tubing is pushed in all the way and there is still a leak, replace the

push to connect fitting. Wipe all connections checked with Soap Water once test is complete.

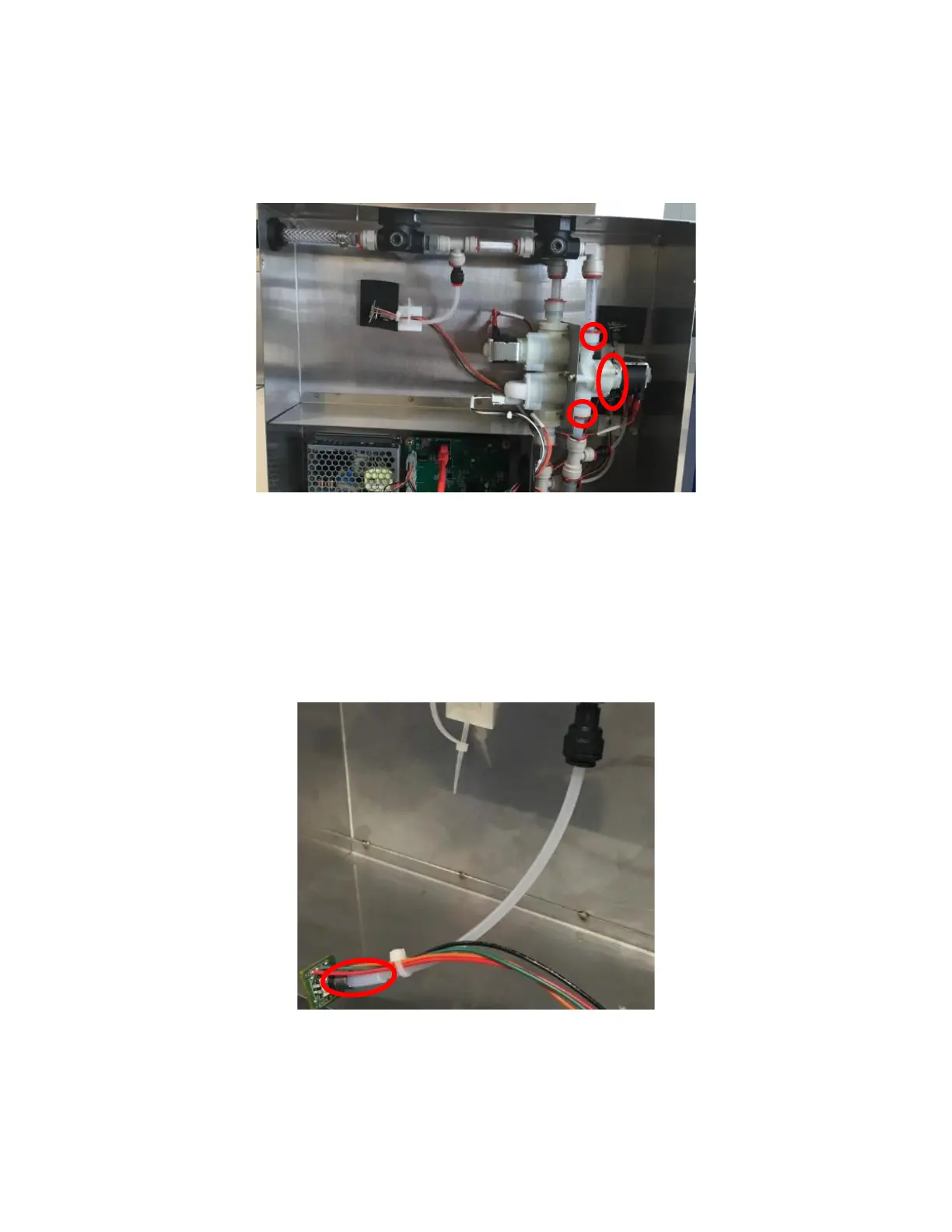

iv. Check the Pressure Transducer itself for leak. Cut the cable tie holding the Pressure Transducer against the

foam so soap water can be applied around the barb connection on the Pressure Transducer Board. Check

one pressure transducer at a time and immediately wipe all the Soap Water once test is complete. See

Figure 50. If leak is found on the Pressure Transducer, replace the entire Pressure Transducer Assembly.

v. Check the Pressure Regulator itself for leaks by applying soap solution to the body of the Pressure

Regulator. If the leak is coming from the Pressure Regulator itself, replace the Pressure Regulator and all

fittings. Apply 3-layers of Teflon tape in clockwise direction and tighten the fitting to proper torque setting.

Refer to Appendix B: John Guest Torque Settings for proper Torque Setting. See Figure 51a and 51b.

Loading...

Loading...