Insulation Blowing Machine M99

X-Floc Dämmtechnik-Maschinen GmbH Page 13 of 51

Rosine-Starz-Straße 12 · 71272 Renningen · Germany

Phone +49-7159-80470-30 · Fax -40 | info@x-floc.com · www.x-floc.com

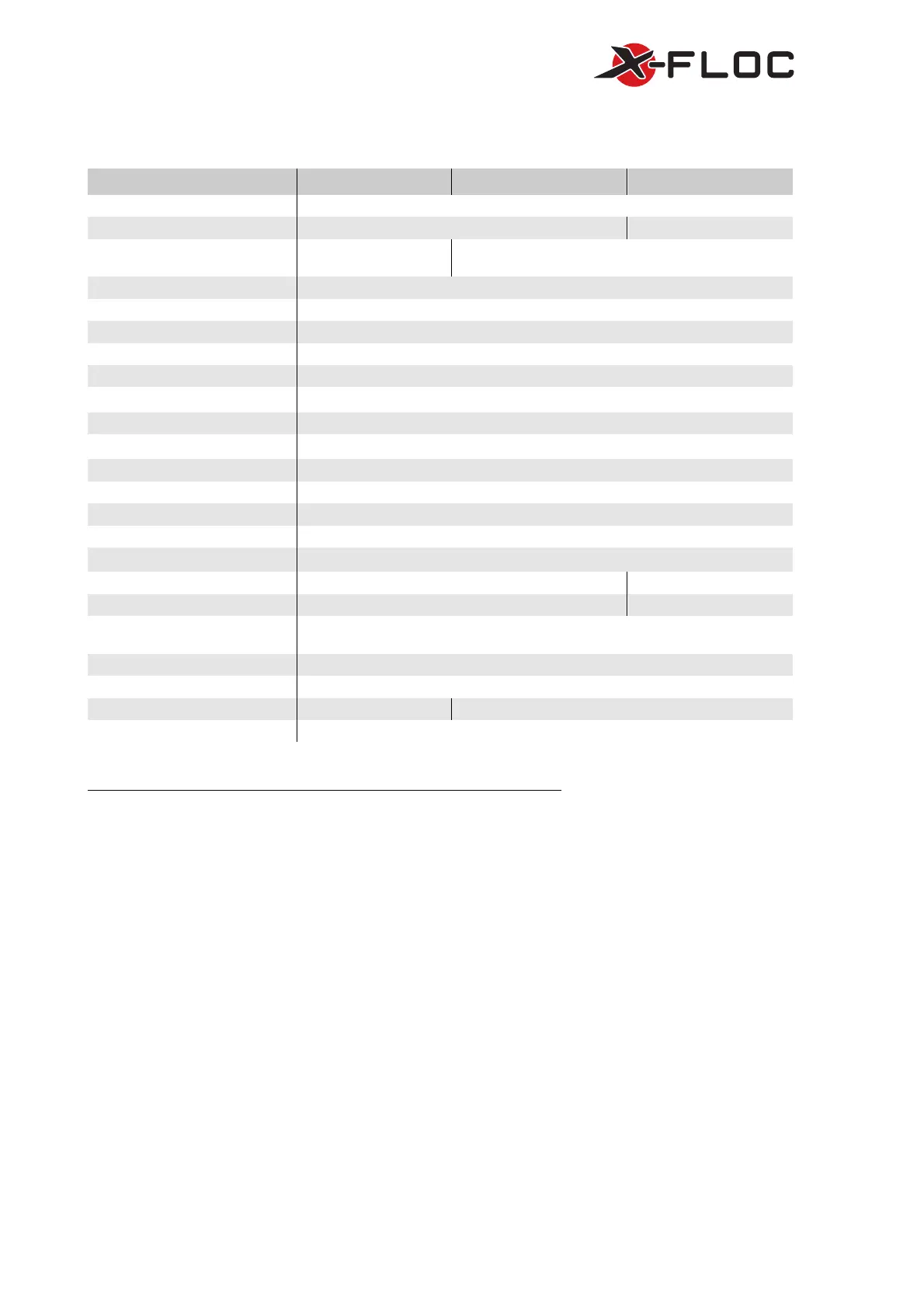

3.4.2 Technical Details

Specifications M99 M99-DS M99-DS-Pro

Dimensions (Ø×H) 640×1400

mm

Empty weight 110

kg 111

kg

Power supply

230

V / 50

Hz / 16

A

(230

V / 50

Hz / 10

A)*¹

230

V / 50-60

Hz / 16

A

(230

V / 50-60

Hz / 10

A)*¹

Rated power 3,6

kW

Engine power 0,75

kW

Adjustable fan power 2× 1,45

kW

Adjustable delivery pressure max. 325

mbar

Minimum blowing pressure 245

mbar

Air volume (nominal/gauged)

440/350

m³/h

Material flow rate*¹ max. 600

kg/h

Packaging density*²

max. 145

kg/m³

Shredding Conditioning unit [9]

Filling hopper 200

L

Filling height 1400

mm

Intake socket [11] NW75 (3‘‘)

Outlet [7]*³

NW63 (2

½

‘‘)

Machine control KFB

3 and FFB

400 FFB

2000-Pro

Automatic blowing ×

Conveying height without/with

an amplifier

max. 20

m / 40

m

Air supply unit, connectible 2× High performance-radial ventilators

Airlock feed gate Manually adjustable in 17 levels (1…1,5…2…8,5…9)

Airlock rotational speed control ×

Temperature during operation -10°C bis +30°C

All figures are approximate values and may differ.

*1) Maximum values depend on the types of insulation materials used and blowing process.

*1) Figures based on average cellulose insulation material.

*2) Based on loose insulation material. Maximum free-flowing bulk density 100

kg/m³.

*3) Direct reduction to NW

63>50 (2½‘‘ >2‘‘) possible.

*4) If necessary, a high performance-radial ventilator can be switched off. The back-up fuse

*4) must contribute 10A at this connection, see chapter 4.1.2.

Loading...

Loading...