Insulation Blowing Machine M99

X-Floc Dämmtechnik-Maschinen GmbH Page 15 of 51

Rosine-Starz-Straße 12 · 71272 Renningen · Germany

Phone +49-7159-80470-30 · Fax -40 | info@x-floc.com · www.x-floc.com

4.1.2 Power Connection

The base for the electric connection is shown on the provided electrical diagram. Pay attention to the

relevant VDE-guidelines (Association for Electric, Electronic and Information Technologies), the accident

prevention regulations and operating the insulation blowing machine outside the Federal Republic of

Germany according to national regulations.

WARNING!

Warning against dangerous electrical voltage!

Damaged cable connections and touching the electric cables can lead to electrocutions and sever

injury or death.

Before starting the connection work, ensure that the machine has been assembled

correctly and the hopper [3] is fixed to the bottom of the machine [10].

Before operating the electric switchboard [6], move the net adaptor.

Operating the electric switch board may only be done by qualified personnel.

Before starting the connection work, the electrical installation requirements must be checked over.

The machine is not protected against long periods of continuous overvoltage. In order to avoid damaging

the machine, the existing power network’s connection value must be sufficient for the whole system. The

machine’s connection may only be made over a particular supply point, in the worksite power distribution

point. If the mains voltage is too low and the supply cables are inadequately dimensioned, the machine’s

overall power can be reduced.

When using the cable reel, care must be taken to ensure that these are fully laid out. There is a risk of

overheating and fire! Take local conditions into account and prevent the supply cable from being damaged

when laying them out. The operating personnel must not be obstructed.

The insulation blowing machine M99 requires a power supply of 230

V / 50

Hz (M99), 230

V / 50-60

Hz (M99-

DS/M99-DS-Pro). The connection is made via the three-phase supply. The supply cable must be compatible

with the H07

RNF (3× 2,5

mm) version. The protective contact must be earthed correctly, the backup fuse

must amount to 16

A. Voltage or frequency deviations of up to 5% are permissible. Connect the supply

cable to a separately secured power circuit.

Connect the net adaptor to the electrical switchboard’s [6] main connection X10 [27]. Set the blower selector

switch Q2 [20] to position “2“(M2, M3). If there is a lack of power or the performance requirements are lower

than is normally required, the machine can be put into operation using only one high performance-radial

ventilator. At this connection, the backup fuse only has to be 10

A. Set the blower selector switch to position

“1” (M2).

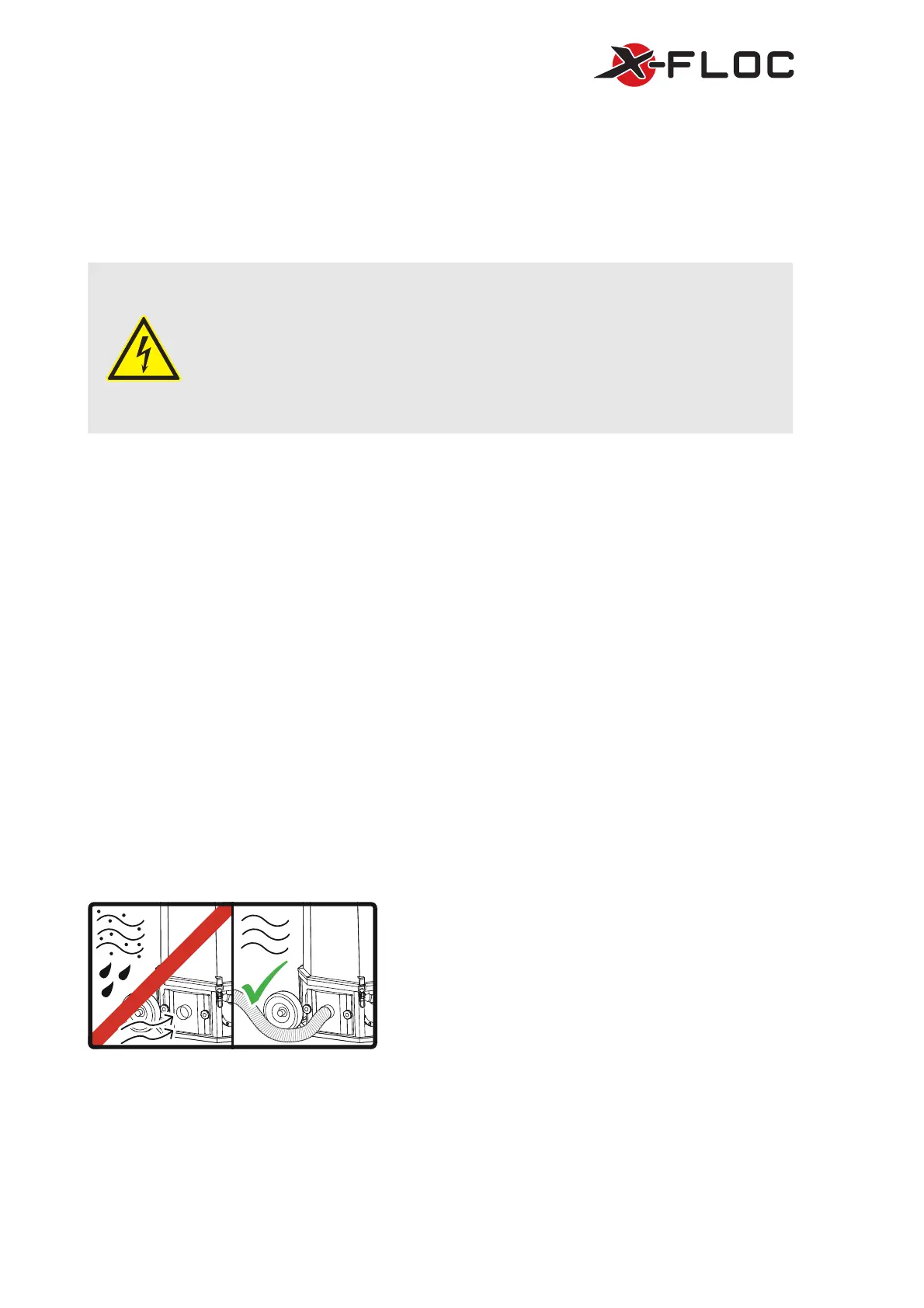

4.1.3 Suction Hood

Figure 9: Incoming air through hose connection

The fresh air is vacuumed via the suction hood’s [12] intake

socket NW75 [11] and must be clean every time. If the

surrounding air’s particle load is too heavy, fresh air must

be blown into the area using the hose (up to 5m long)

provided in the delivery contents from an area with clean

air. The hose connection should be chosen so that no

material and dirt can be sucked in and hose opening can

always be seen. The hose connection should regularly be

checked for dirt and blockages and be cleaned if necessary.

The suction hose, with a nominal diameter NW75, must be

put over the intake socket and hermetically sealed with a

hose clamp NW75.

Loading...

Loading...