Insulation Blowing Machine M99

X-Floc Dämmtechnik-Maschinen GmbH Page 29 of 51

Rosine-Starz-Straße 12 · 71272 Renningen · Germany

Phone +49-7159-80470-30 · Fax -40 | info@x-floc.com · www.x-floc.com

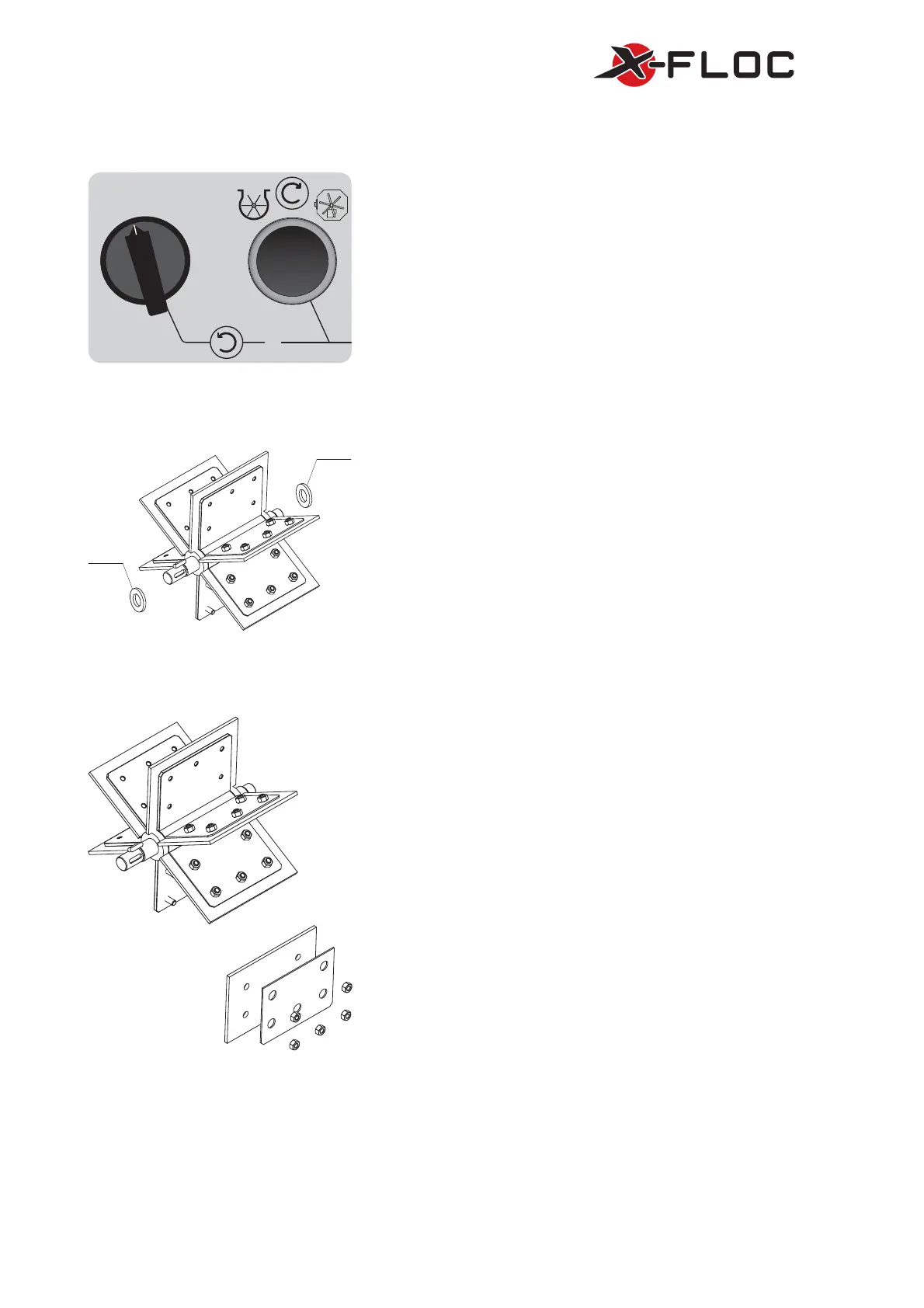

6.1.2 Conditioning Unit & Rotary Airlock Maintenance Function

Figure 24: Control elements for maintenance

For maintenance purposes and to rectify any faults, the rotary

airlock [8] and the conditioning unit [9] can be run both

forwards and backwards.

For forward rotation, press the rotary airlock and conditioning

unit maintenance button S1/S2 [26] .

For reverse rotation for the rotary airlock and conditioning unit,

turn the reverse operation selector Q5/S1 [25] and the press the

rotary airlock and conditioning unit maintenance button.

6.1.3 Sealing Rings

Dichtring

Dichtring

Figure 25: Rotary airlock [8] with sealing rings

Covered between the rotary airlock [8] and the outlet console

are felt rings which protect the bearing position from

contamination.

The sealing rings should be oiled with vegetable oil regularly.

If there is any abrasion on the sealing rings, then there is a

higher amount of leaked air during operation. Damaged and

worn sealing rings must be replaced.

For further information, please contact customer service.

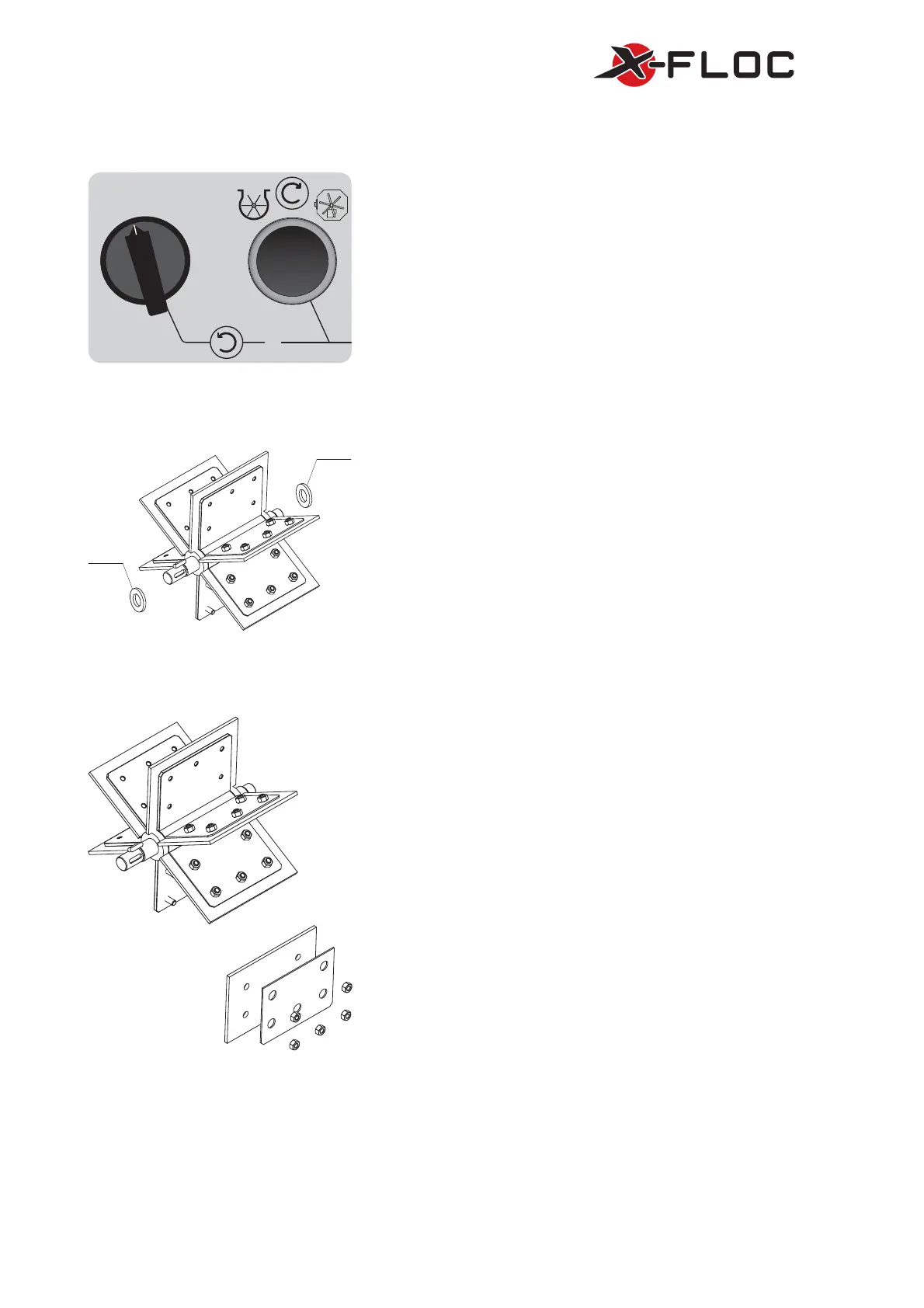

6.1.4 Rotary Airlock & Gaskets

Figure 26: Rotary airlock [8] with gaskets

The gaskets must be replaced if there are any visible entry-

holes, excessive abrasion on the gaskets and/or gauged

blowing pressure of >230 mbar (at maximum blower power).

To turn the rotary airlock [8] to the right position, press the

rotary airlock maintenance button S1/S2 [26] so that an airlock

chamber is directly accessible. If necessary, the conditioning

unit [9] must be removed by undoing the central fastening bolt

from the machine’s bottom [10].

Loosen the female screw from the clamp sheet and take off the

screw with the clamp sheet. Replace the worn gaskets with

new ones, aligning them in centrically and screw back on with

the clamp sheet and female screw. Tighten with a tightening

torque of approx. 4

Nm. Repeat this procedure for the rest of

the airlock chamber. After replacing the gaskets, lubricate the

airlock contact surfaces with silicon spray. Let the insulation

blowing machine run empty for approx. 1-4 hours.

Loading...

Loading...