Insulation Blowing Machine M99

Page 28 of 51

X-Floc Dämmtechnik-Maschinen GmbH

Rosine-Starz-Straße 12 · 71272 Renningen · Germany

Phone +49-7159-80470-30 · Fax -40 | info@x-floc.com · www.x-floc.com

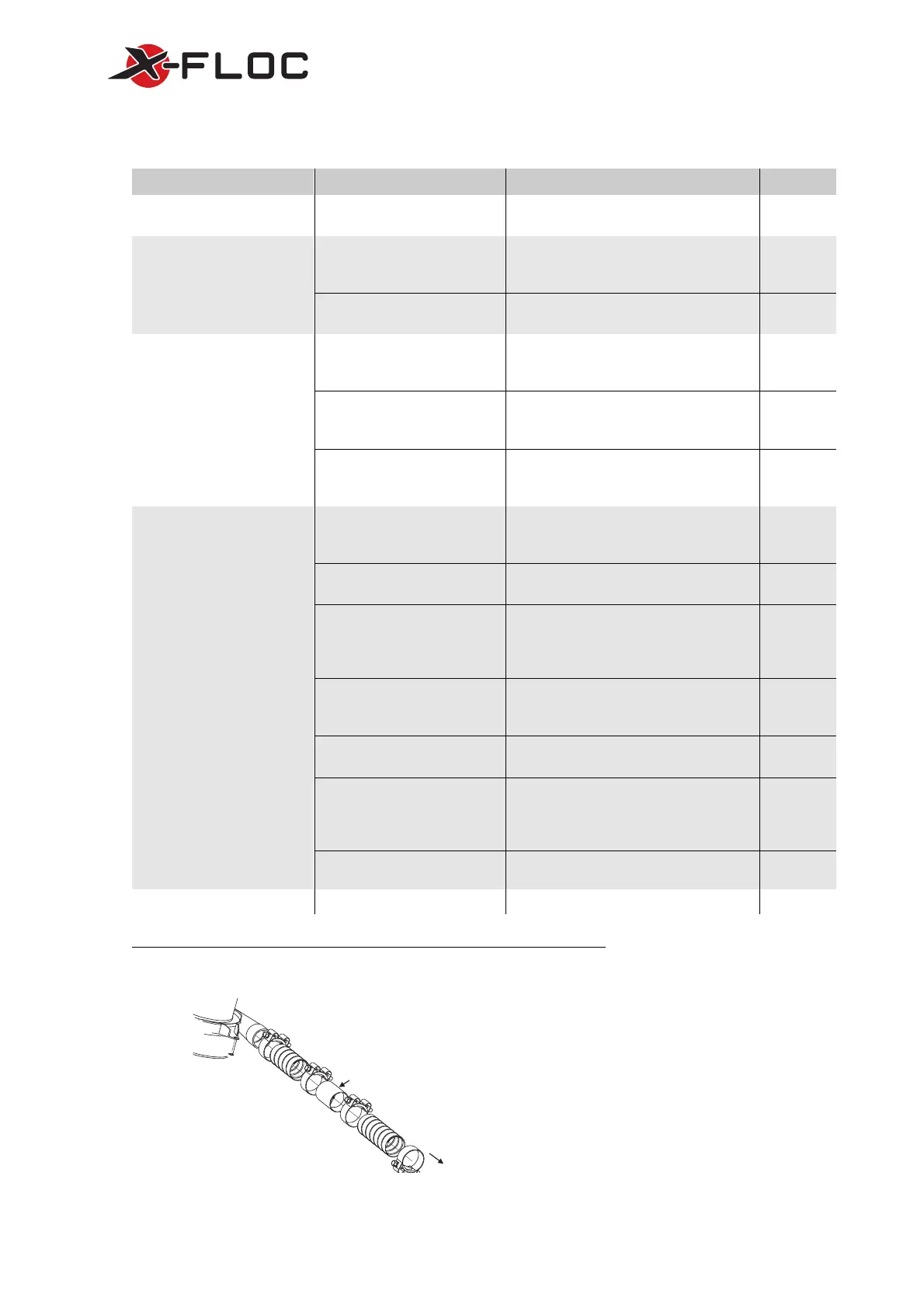

6.1.1 Maintenance Intervals

Interval Module Activity Prod. no.

One-off, after 10 operating

hours

Machine’s bottom [10]

Check the hosing for tightness and if

necessary, tighten the hose clamps.

-

Before and after every

commissioning

Air filter Check the air filter for contamination

and if necessary, clean or replace the air

filter.

3450

Outlet NW63 (2

½

‘‘) [7]

Check the blowing pressure using the

pressure gauge. Should be >245

mbar.

-

Every 20 operating hours,

or 1×/week

Airlock feed gate Check the airlock feed gate and if

necessary, scrub off any hardened

material.

-

Rotary airlock [8]

Check the gaskets in the rotary airlock

for wear and tear and if necessary,

replace the gaskets.

1504

Conditioning unit [9]

Check the conditioning unit for visible

deformations and if necessary, get rid of

any foreign objects.

-

Every 80 operating hours,

or 1×/month, for irregular

commissioning 1×/year

Angular gearbox Check the bevel gears for wear and tear,

slackness and grease. If necessary,

grease the bevel gears.

2202

Hose lines Check the hose lines for damages and if

necessary, replace the hose lines.

-

Pressure detection unit

(M99-DS-Pro)

Check the hose connections for

contamination and if necessary, clean

and blow through the hose connections

from the check valve.

-

Radial ventilators Check the carbon brushes for abrasion

and if necessary, replace the carbon

brushes.

4233

Check valves* Check the check valves for loose

movement.

-

Rotary airlock [8]

Check the felt sealing rings for abrasion

and if necessary, oil the felt rings with

vegetable oil or replace the sealing

rings.

o. r.

Cooling air filter

Check the cooling air filters for function

and if necessary, clean or replace them.

-

Every 400 operating hours Radial ventilators Replace the carbon brushes. 4233

*

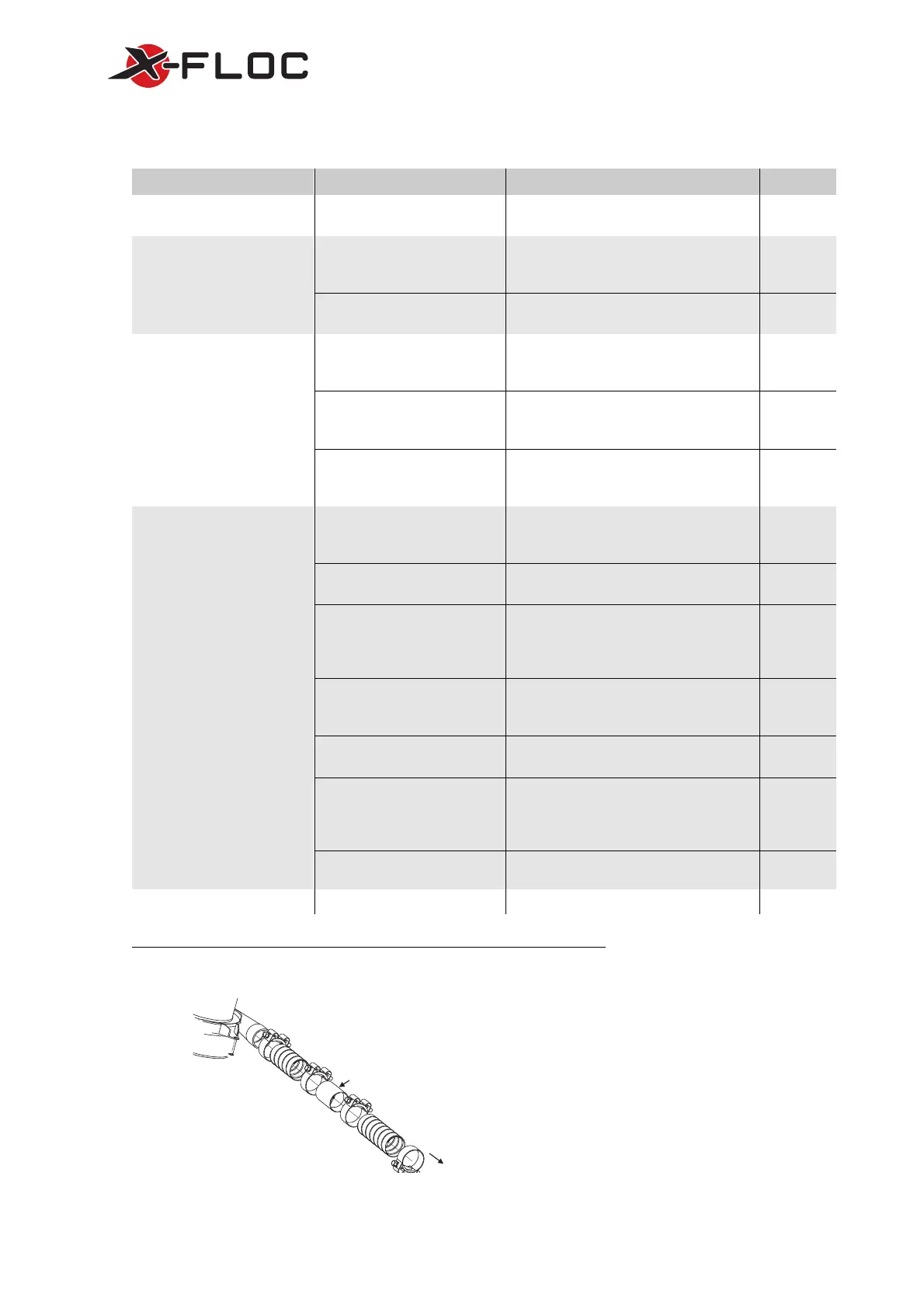

The check valves are located in the machine’s bottom [10] between the air

supply unit and the rotary airlock [8].

Air supply

Rotary airloc

Check valve

Figure 23: Check valve position

Loading...

Loading...