Insulation Blowing Machine M99

Page 26 of 51

X-Floc Dämmtechnik-Maschinen GmbH

Rosine-Starz-Straße 12 · 71272 Renningen · Germany

Phone +49-7159-80470-30 · Fax -40 | info@x-floc.com · www.x-floc.com

WARNING!

Warning of danger of injury!

There is a greater risk of injury when gripping the machine’s hopper extension [1] and the

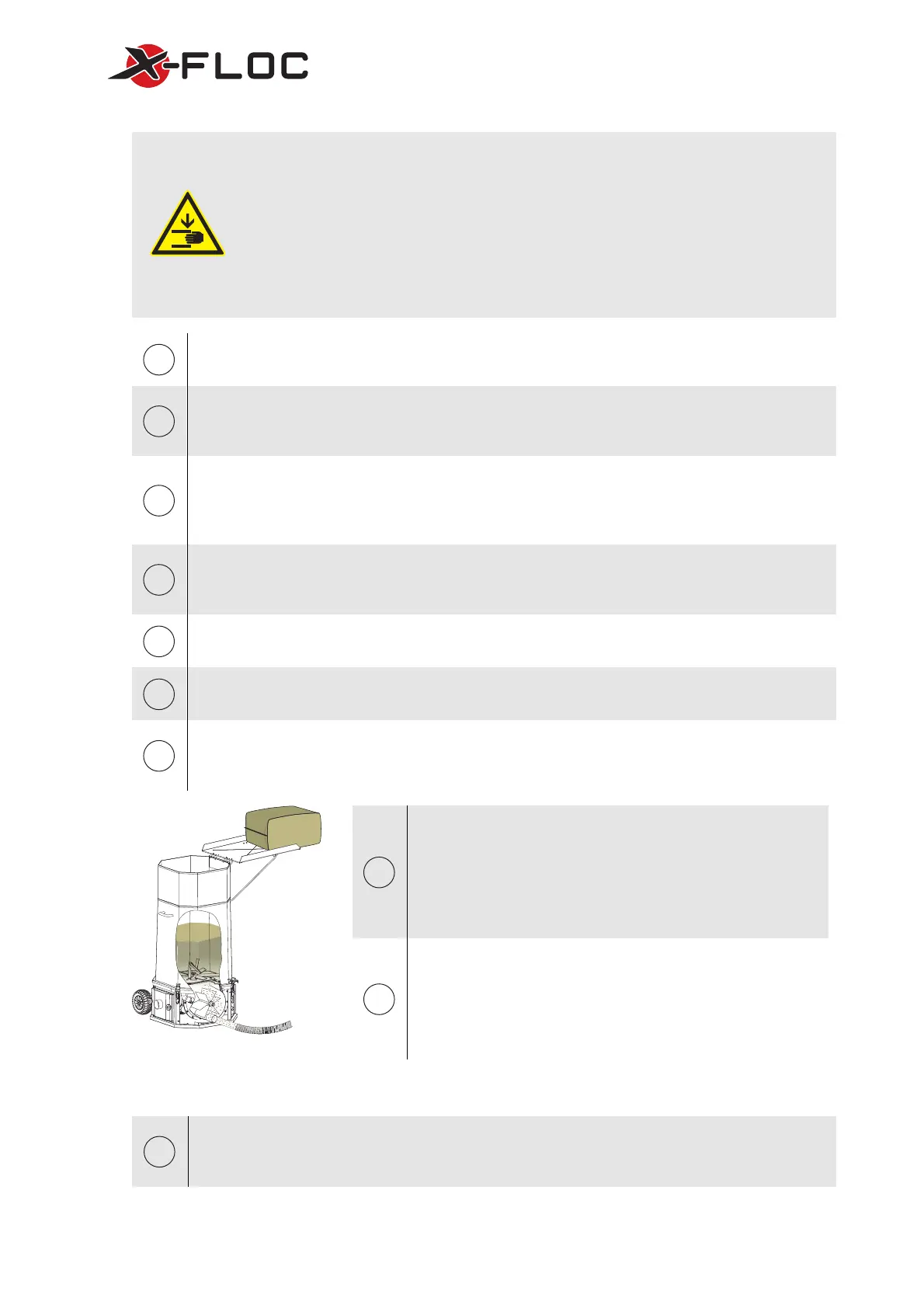

hopper [3] and when the insulation material is contaminated with foreign objects. Foreign

objects can damage machine parts and may be ejected out of the machine uncontrollably.

When filling the machine, during initial operation and all other operations, never grip the

hopper extension or the hopper!

Never grip in the conditioning unit [9]!

Make sure that no foreign objects reach the machine!

1

When using a sack support [16] (see chapter 7.1.1), place it on top of the hopper extension [1] as

seen in figure 2, chapter 3.1.

2

Connect the control and conveyor line as seen in chapter 4.1. Keep the conveyor line ready.

KFB

3: Set the toggle switch [32] to position Material [33] and activate the air and material flow.

FFB

400: Activate air and material flow by pressing the Material [38] button.

3

Open the insulation bales, get rid of the packaging material and put the insulation material into

the hopper extension. When using the sack support, place the insulation bales on top of the sack

support, get rid of the packaging material and push the insulation material into the hopper

extension.

4

When operating the insulation blowing machine M99, we recommend the first insulation bales be

put into the machine in small pieces and loosened using the conditioning unit maintenance button

S1/S2 [26]..

5

Blow the transported insulation material with the conveyor line at the desired place. If required,

increase or reduce the air and material flow volume, see chapter 5.1.2. and 5.2.2.

6

Alternatively, the material flow can be adjusted manually using the airlock feed gate, see

chapter 5.4.

7

M99/M99-DS: The blower power should be set using the blower power selector R1 [23].

The additional blower can be turned on (M2, M3) or off (M2) using the blower selector switch Q2

[20]. M99-DS-Pro: Set the blower power directly using the radio remote control FFB

2000-Pro.

Figure 21: Minimum filling level

8

For processing hard and/or long-fibred unidimensional

aligned insulation material, or for increasing power, an

additional amplifier and vacuum station can be used. For

more information, please contact customer service or refer to

the Amplifier /Vacuum Station VS28/VS33 operating

instructions.

9

Put in the insulation material bales into the hopper extension in

regular intervals. Continue the blowing process. In order to

guarantee a flawless operation, the conditioning unit [9]

should always be sufficiently filled with insulation material

(minimum filling level).

5.7.4 Decommissioning

10

When decommissioning the insulation blowing machine, ensure that the remaining insulation

material from the hopper and the conveyor line is blown out. Set the main switch Q1 [19] to

position “0”. Pull out the net adaptor.

Loading...

Loading...