ENGINE

Inspecting the Cylinder Block and Components

12/05

6LY3 Service Manual

5-47

© 2007 Yanmar Marine International

Inspecting the Main Bearings

1. Check each bearing insert for flaking material,

seizure or burning of the bearing surface.

2. Replace the bearings if any discrepancies are

found.

3. Investigate the cause of any problems

discovered with the main or connecting rod

bearings.

4. Install the main bearing inserts.

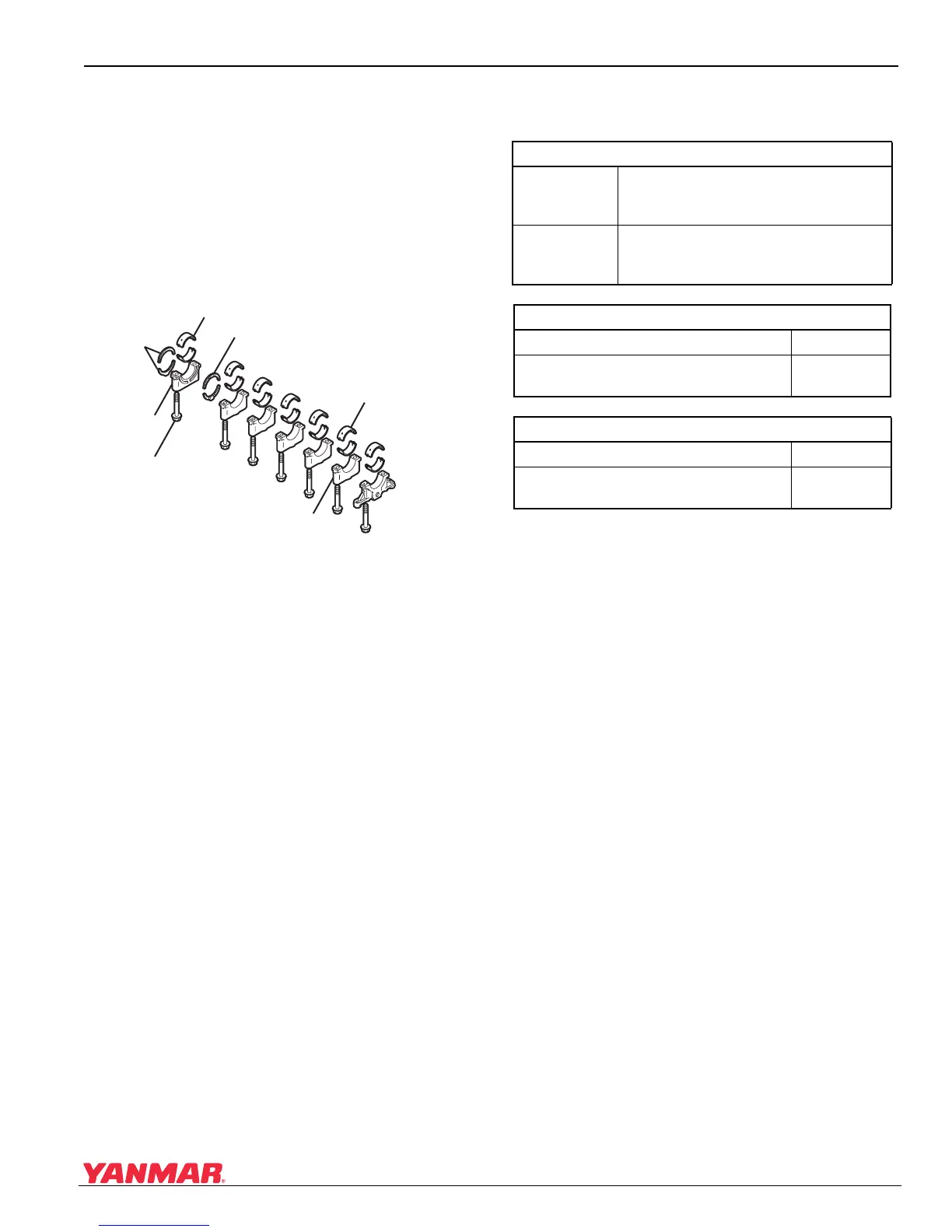

Figure 5-63

Figure 5-63

1 – Thrust Bearing (Flywheel End)

2 – Main Bearing (Basic)

3 – Thrust Bearing (Inboard)

4 – Main Bearing (Intermediate)

5 – Main Bearing Cap (Intermediate)

6 – Main Bearing Cap Bolt

7 – Main Bearing Cap

5. Tighten the cap to the specified torque.

6. Measure the inner diameter of the main bearing

inserts.

NOTICE: When assembling the bearing cap, keep

the following in mind:

1. The lower bearing insert (cap side) has no oil

groove.

2. The upper bearing insert (block side) has an oil

groove.

3. Check the cylinder block alignment number.

4. The “FW” on the cap must face the flywheel end

of the engine.

0005648

(4)

(2)

(3)

(1)

(7)

(6)

(5)

Main Bearing Bolt Torque

New Bolt

245-265 N·m

(25.0-27.0 kgf·m)

(180-195 lb-ft)

Used Bolt

225-245 N·m

(23.0-25.0 kgf·m)

(166-180 lb-ft)

Bearing Inside Diameter

Standard Limit

75.000-75.045 mm

(2.9527-2.9545 in.)

—

Bearing Thickness

Standard Limit

2.487-2.500 mm

(0.0979-0.0984 in.)

—

Loading...

Loading...