ENGINE

Inspecting the Cylinder Block and Components

5-46 6LY3 Service Manual

© 2007 Yanmar Marine International

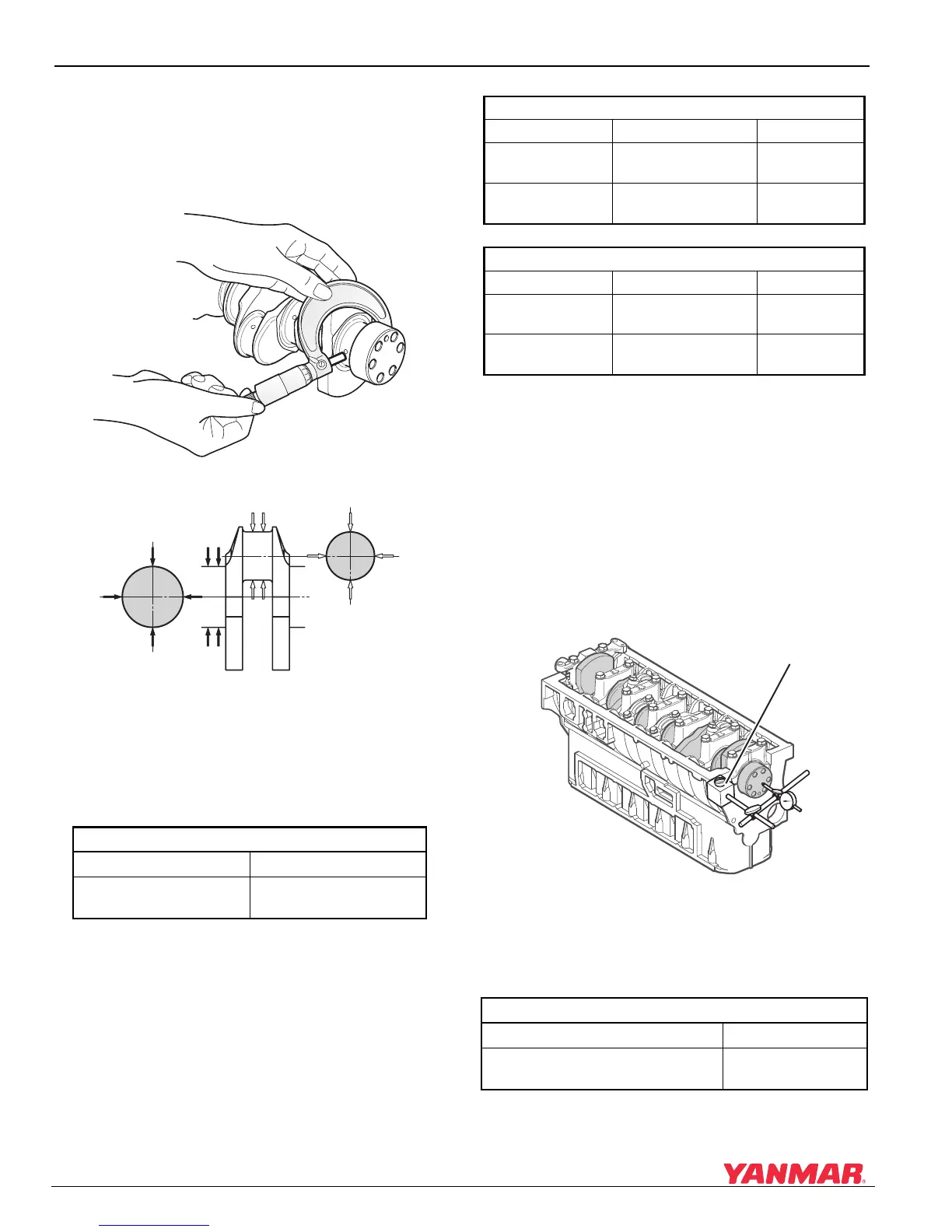

Measuring the Crank Pins and the Main

Bearing Journals

• Measure the outside diameter, roundness and

taper at each crank pin and journal as shown in

Figure 5-60 and Figure 5-61.

Figure 5-60

Figure 5-60

Figure 5-61

Figure 5-61

• Resurface the crankshaft pins and main bearing

journals if measurements exceed the listed

specifications.

• Replace if the defect is excessive.

NOTICE: To determine the oil clearance of the

crank pin, measure the inside diameter of the

connecting rod crank pin bearing.

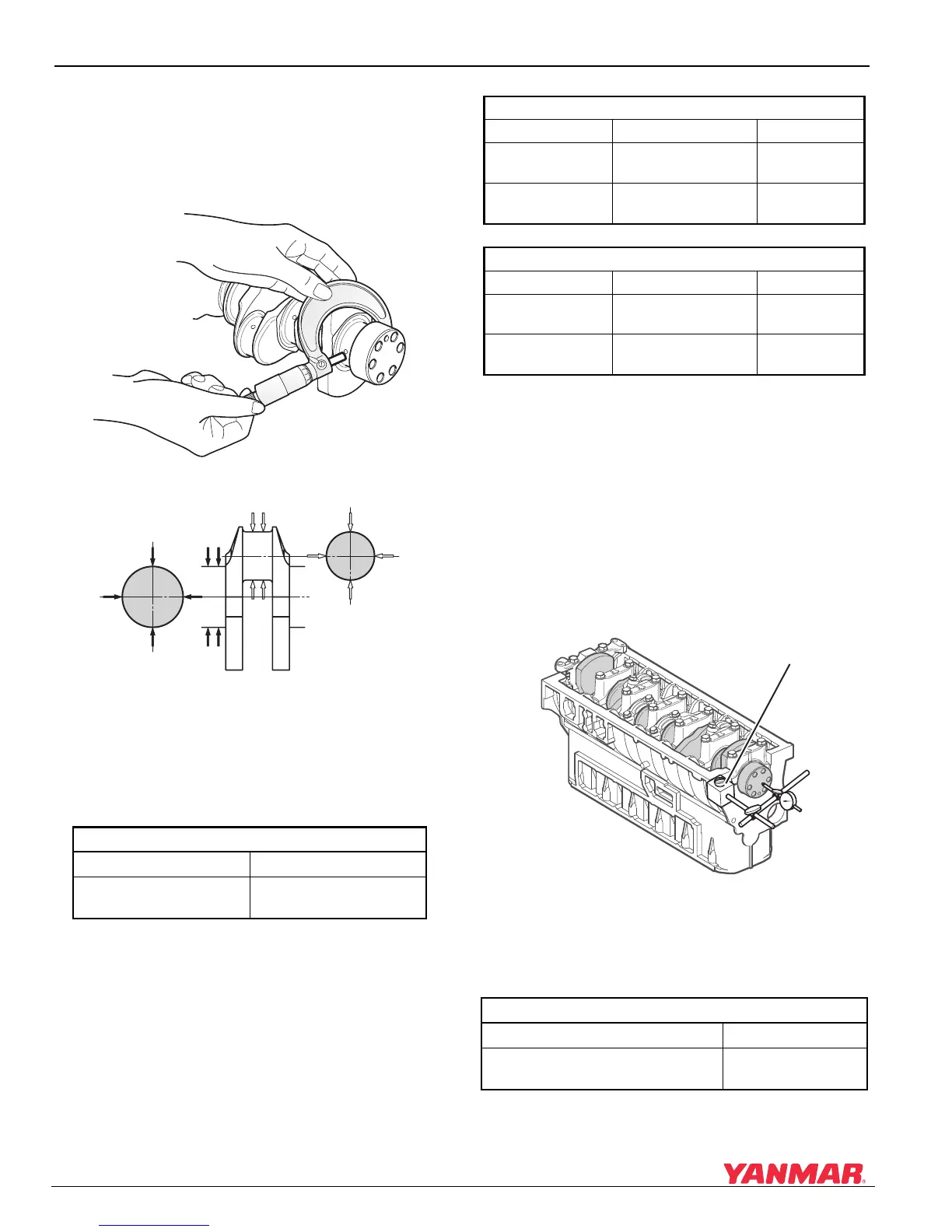

Inspecting the End Play of the Crankshaft

• Assemble the crankshaft to the engine block.

• Tighten the main bearing caps to the specified

torque.

• Move the crankshaft along its horizontal axis from

end to end.

• Install a dial indicator (Figure 5-62, (1)) on one

end of the crankshaft to measure crankshaft end

play.

Figure 5-62

Figure 5-62

1 – Dial Indicator

• Replace the thrust bearing if it is worn beyond the

stated limit.

Crankshaft Pin and Main Bearing Journals

Item Limit (Diameter)

Roundness / Taper

0.01 mm

(0.0003 in.)

0005645

0005646

Crank Pin

Standard Limit

Outside Diameter

64.952-64.964 mm

(2.5571-2.5576 in.)

64.90 mm

(2.5551 in.)

Oil Clearance

0.036-0.093 mm

(0.0014-0.0036 in.)

0.160 mm

(0.0062 in.)

Crank Journal

Standard Limit

Outside Diameter

74.952-74.964 mm

(2.9508-2.9513 in.)

74.90 mm

(0.0062 in.)

Oil Clearance

0.036-0.093 mm

(0.0014-0.0036 in.))

0.15 mm

(0.0059 in.)

Crankshaft Side Clearance

Standard Limit

0.132-0.223 mm

(0.0051-0.0087 in.)

0.29 mm

(0.0114 in.)

0005647

(1)

Loading...

Loading...