19 Troubleshooting

122 YASKAWA TOEPC71061737B GA800 Drive Installation & Primary Operation

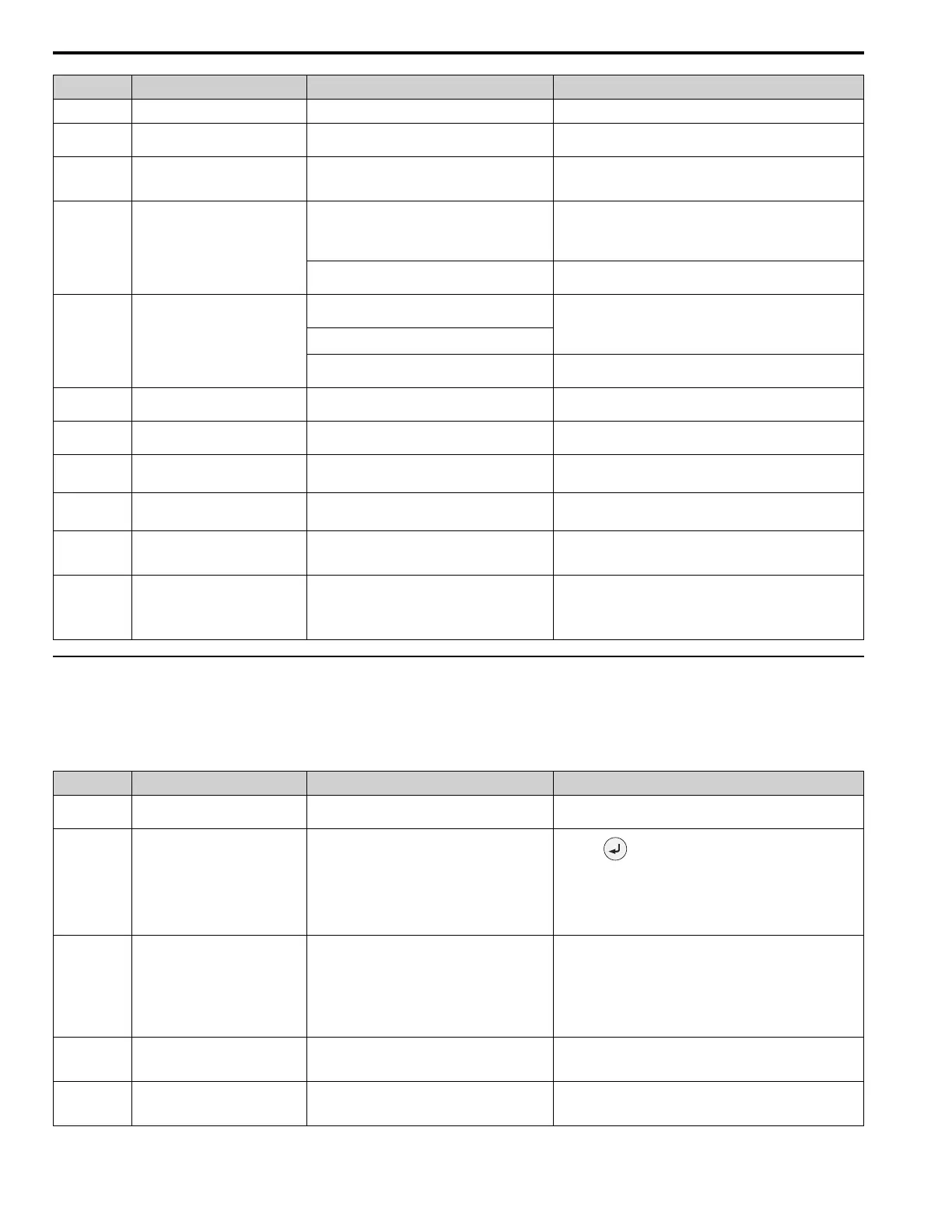

Code Name Causes Possible Solutions

PGoH Encoder (PG) Hardware Fault

The encoder cable is disconnected. Correct any disconnected wires in the encoder cable.

rUn Motor Switch during Run

The drive received a Motor 2 Selection [H1-xx = 16]

during run.

Make sure that the drive receives the Motor 2 Selection while the

drive is stopped.

SE Modbus Test Mode Error

MEMOBUS/Modbus communications self-

diagnostics [H1-xx = 67] was done while the drive

was running.

Stop the drive and do MEMOBUS/Modbus communications self-

diagnostics.

STo Safe Torque OFF

Safe Disable inputs H1-HC and H2-HC are open. • Make sure that the Safe Disable signal is input from an external

source to terminal H1-HC and H2-HC.

• When the Safe Disable function is not in use, use a jumper to

connect terminals H1-HC and H2-HC.

There is internal damage to the two Safe Disable

channels.

Replace the board or the drive. Contact Yaskawa or your nearest

sales representative to replace the board.

SToF Safe Torque OFF Hardware

One of the two terminals H1-HC or H2-HC received

the Safe Disable input signal.

The Safe Disable input signal is wired incorrectly.

• Make sure that the Safe Disable signal is input from an external

source to terminals H1-HC or H2-HC.

• When the Safe Disable function is not in use, use a jumper to

connect terminals H1-HC and H2-HC.

There is internal damage to one Safe Disable channel. Replace the board or the drive. Contact Yaskawa or your nearest

sales representative to replace the board.

TiM Keypad Time Not Set

There is a battery in the keypad, but you have not set

the date and time.

Use the keypad to set the date and time.

TrPC IGBT Maintenance Time (90%)

The IGBT is at 90% of its expected performance life. Replace the IGBT or the drive. For more information, contact

Yaskawa or your nearest sales representative.

UL3 Undertorque Detection 1

A fault occurred on the machine.

Example: There is a broken pulley belt.

Examine the machine and remove the cause of the fault.

UL4 Undertorque Detection 2

A fault occurred on the machine.

Example: There is a broken pulley belt.

Examine the machine and remove the cause of the fault.

UL5 Mechanical Weakening Detection 2

The drive detected undertorque as specified by the

conditions for mechanical weakening detection set in

L6-08 [Mechanical Fatigue Detect Select].

Examine the machine for deterioration.

Uv Undervoltage

The drive input power voltage is changing too much. • Examine the input power for problems.

• Make the drive input power stable.

• If the input power supply is good, examine the magnetic

contactor on the main circuit side for problems.

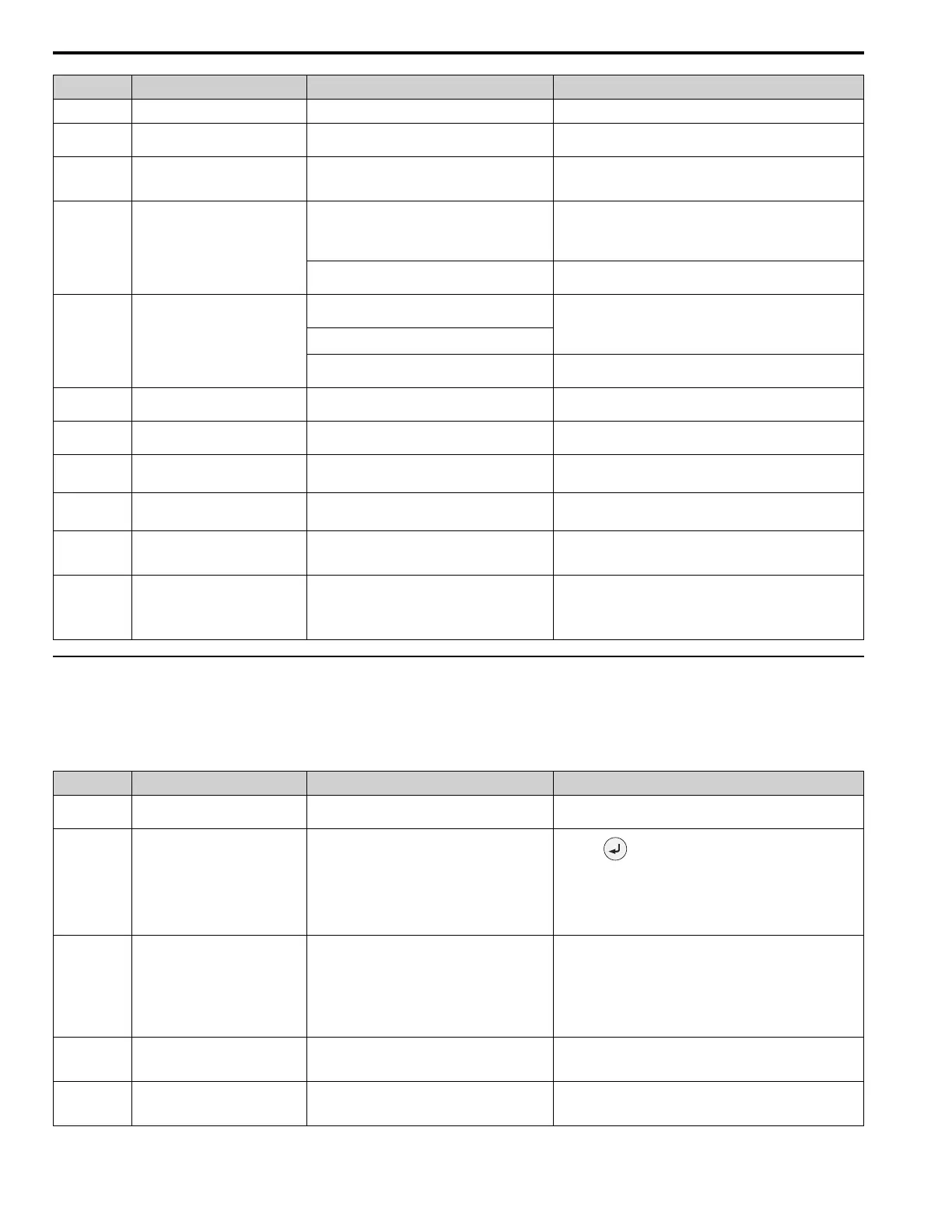

◆ Parameter Setting Errors

Parameter setting errors occur when multiple parameter settings do not agree, or when parameter setting values are

not correct. Refer to the table in this section, examine the parameter setting that caused the error, and remove the

cause of the error. You must first correct the parameter setting errors before you can operate the drive. The drive will

not send notification signals for the faults and alarms when these parameter setting errors occur.

Code Name Causes Possible Solutions

oPE01 Drive Capacity Setting Error

The value set in o2-04 [Drive Model (KVA) Selection]

does not agree with the drive model.

Set o2-04 to the correct value.

oPE02 Parameter Range Setting Error

Parameters settings are not in the applicable setting

range.

1. Push to show U1-18 [oPE Fault Parameter], and find

parameters that are not in the applicable setting range.

2. Correct the parameter settings.

Note:

If more than one error occurs at the same time, other oPExx

errors have priority over oPE02.

oPE03 Multi-Function Input Setting Err

The settings for these parameters do not agree:

• F3-10 to F3-25 [Terminal D1 to DF Function

Selection]

• H1-01 to H1-08 [Terminals S1 to S8 Function

Selection]

• H7-01 to H7-04 [Virtual Multi-Function Inputs 1

to 4]

Correct the parameter settings.

oPE05 Run Cmd/Freq Ref Source Sel Err

The setting to assign the Run command or frequency

reference to an option card or the pulse train input is

incorrect.

Correct the parameter settings.

oPE06 Control Method Selection Error

A1-02 = 1, 3, or 7 [Control Method Selection = CL-

V/f, CLV, CLV/PM] is set, but there is no encoder

option card connected to the drive.

• Connect an encoder option card to the drive.

• Set A1-02 correctly.

Loading...

Loading...