10 Troubleshooting

10-24

10.3 Troubleshooting Malfunction Based on Operation and

Conditions of the Servomotor

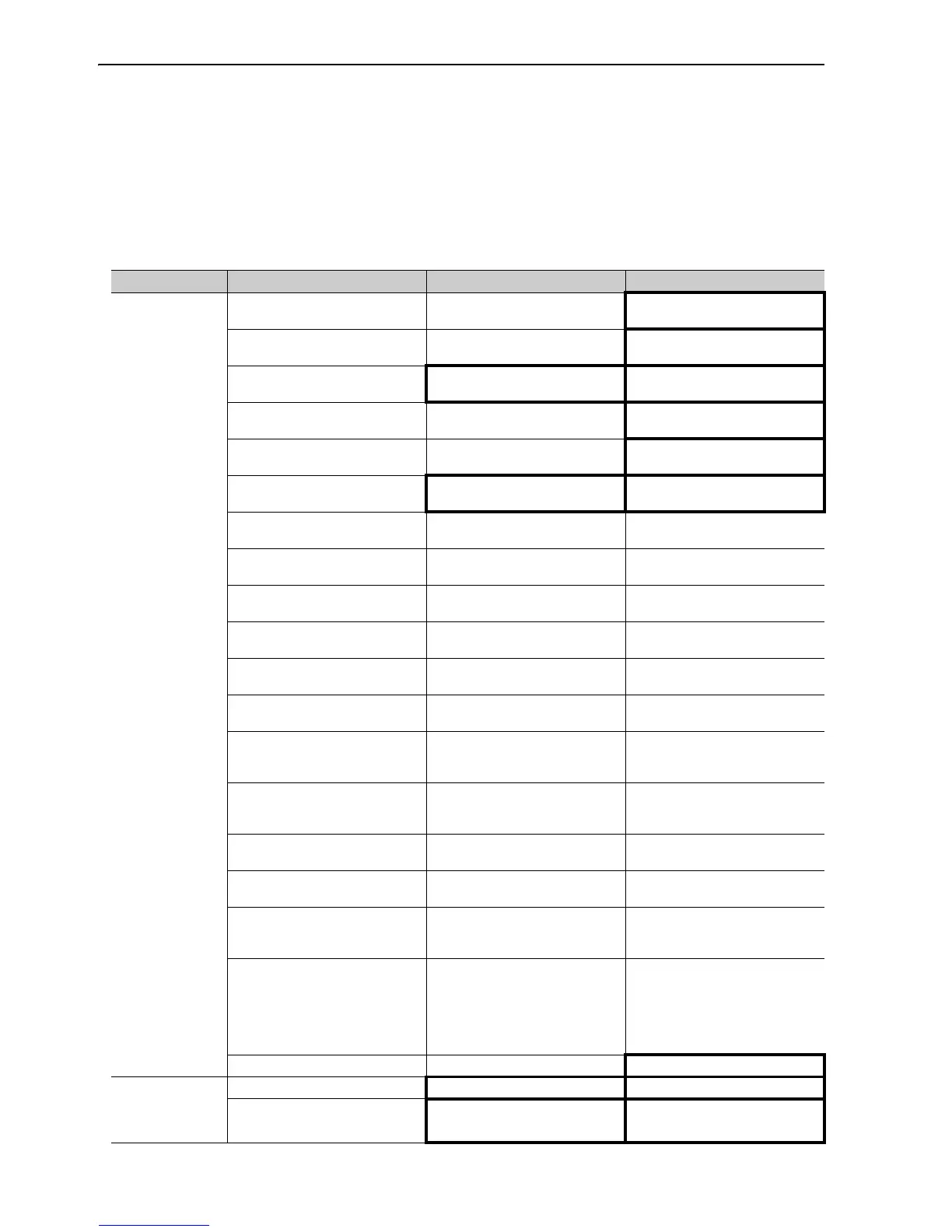

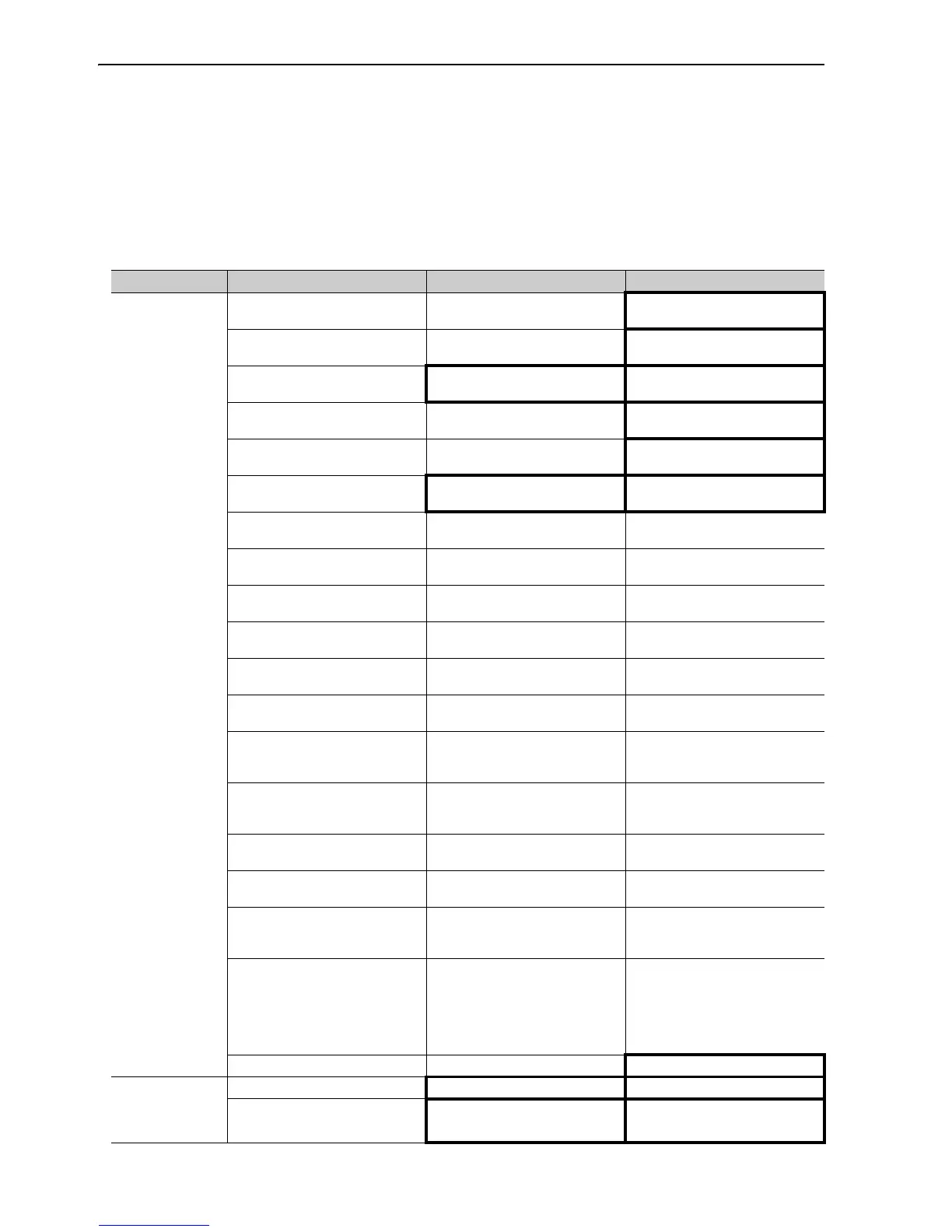

Troubleshooting for the malfunctions based on the operation and conditions of the servomotor is provided in

this section.

Be sure to turn OFF the servo system before troubleshooting items shown in bold lines in the table.

Problem Probable Cause Investigative Actions Corrective Actions

Servomotor Does

Not Start

The control power supply is not

ON.

Check voltage between power sup-

ply terminals.

Correct the power circuit.

The main circuit power supply is

not ON.

Check the voltage between power

supply terminals.

Correct the power circuit.

Wiring of I/O signal connector CN1

faulty or disconnected.

Check if the connector CN1 is prop-

erly inserted and connected.

Correct the connector CN1 connec-

tion.

Servomotor or encoder wiring dis-

connected.

Check the wiring. Correct the wiring.

Overloaded

Run under no load and check the

load status.

Reduce load or replace with larger

capacity servomotor.

Speed/position references not input Check reference input pins.

Input speed/position references cor-

rectly.

Setting for Pn50A to Pn50D "Input

Signal Selection" is incorrect.

Check settings of parameters

Pn50A to Pn50D.

Correct the settings for Pn50A to

Pn50D "Input Signal Selection."

Encoder type differs from parame-

ter setting (Pn002.2).

Check setting of parameter

Pn002.2.

Set parameter Pn002.2 to the

encoder type being used.

Servo ON (/S-ON) input signal

stays OFF.

Check settings of parameters

Pn50A.0 and Pn50A.1.

Set the parameters to turn the Servo

ON (/S-ON) input signal ON.

/P-CON input function setting is

incorrect.

Check parameter Pn000.1.

Set parameters to match the applica-

tion.

SEN input is OFF.

Check the ON/OFF status of the

SEN input.

If using an absolute encoder, turn

the SEN input signal ON.

Reference pulse mode selection is

incorrect.

Check the Pn200.0 setting and the

reference pulse status.

Match the Pn200.0 setting and the

reference pulse status.

Speed control: Speed reference

input is incorrect.

Check V-REF and SG to confirm if

the control method and the input are

agreed.

Correct the control mode selection

parameter, or the input.

Torque control: Torque reference

input is incorrect.

Check V-REF and SG to confirm if

the control method and the input are

agreed.

Correct the control mode selection

parameter, or the input.

Position control: Reference pulse

input is incorrect.

Check Pn200.0 reference pulse

form or sign + pulse signal.

Correct the control mode selection

parameter, or the input.

Position error pulse clear (/CLR)

input is turned ON.

Check /CLR input pins (CN1-14

and -15).

Turn /CLR input signal OFF.

The forward run prohibited (P-OT)

and reverse run prohibited (N-OT)

input signals are turned OFF.

Check P-OT or N-OT input signal.

Turn P-OT or N-OT input signal

ON

.

The safety input signal (/HWBB1 or

/HWBB2) remains OFF.

Check the /HWBB1 or /HWBB2

input signal.

Set the /HWBB1 or /HWBB2 input

signal to ON.

When not using the safety function,

mount the safety function jumper

connector (provided as an acces-

sory) on the CN8.

A SERVOPACK fault occurred. − Replace the SERVOPACK.

Servomotor

Moves

Instantaneously,

and then Stops

Servomotor wiring is incorrect. Check the servomotor wiring. Correct the wiring.

Encoder wiring is incorrect. Check the encoder wiring. Correct the wiring.

Loading...

Loading...