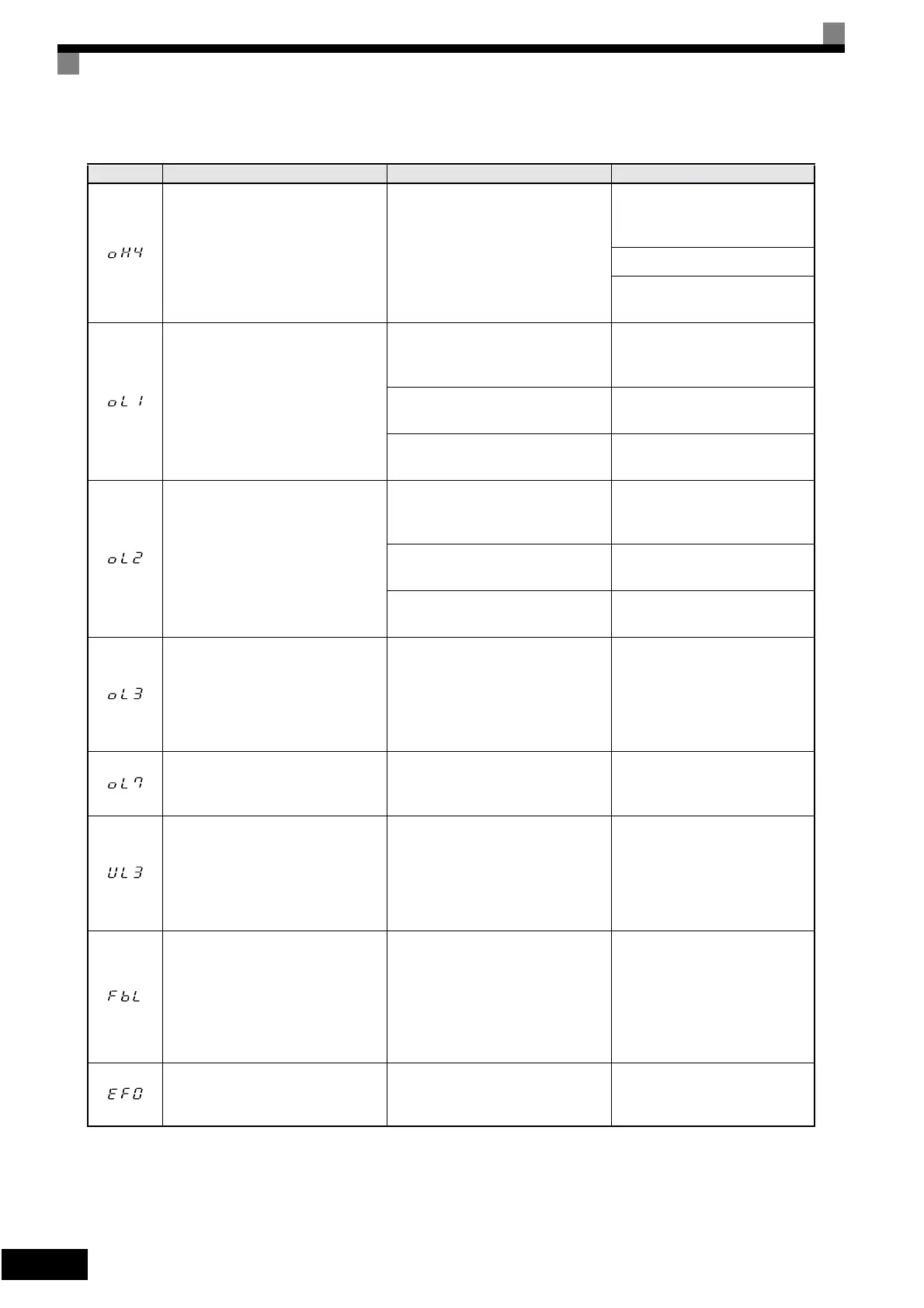

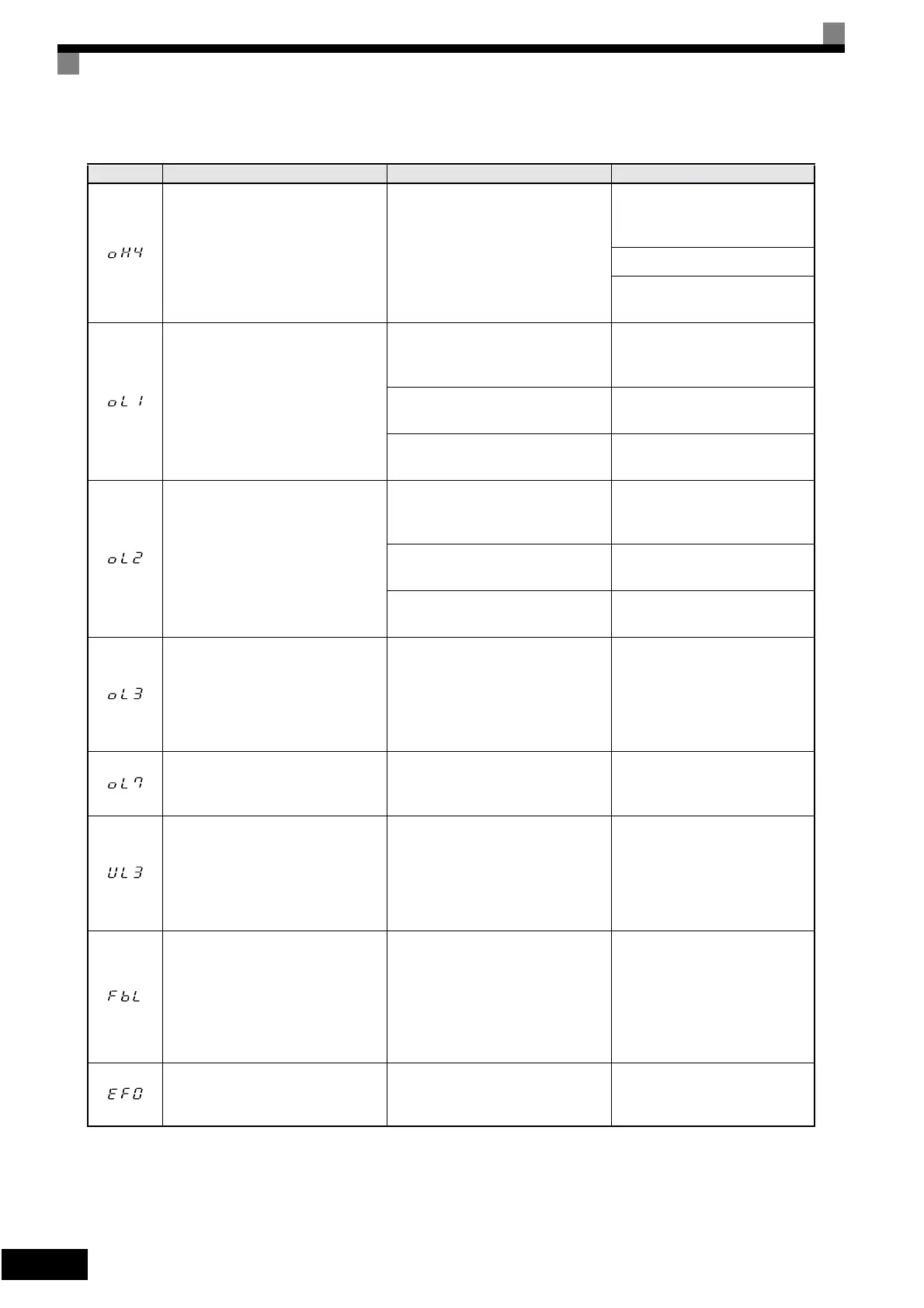

7-4

Motor Overheating Fault

The Inverter will stop according to the

setting of L1-04.

The motor has overheated.

Check the size of the load and the

length of the acceleration, deceler-

ation, and cycle times.

Check the V/f characteristics.

Check the motor temperature

input at terminal A2.

Motor Overload

The motor overload protection func-

tion has operated based on the internal

electronic thermal value.

The load is too heavy. The accelera-

tion time, deceleration time, and cycle

time are too short.

Check the size of the load and the

length of the acceleration, deceler-

ation, and cycle times.

The V/f characteristics voltage is too

high or too low.

Check the V/f characteristics.

The Motor Rated Current (E2-01) is

incorrect.

Check the Motor Rated Current

Setting (E2-01).

Inverter Overload

The Inverter overload protection func-

tion has operated based on the internal

electronic thermal value.

The load is too heavy. The accelera-

tion time, deceleration time and cycle

time are too short.

Check the size of the load and the

length of the acceleration, deceler-

ation, and cycle times.

The V/f characteristics voltage is too

high or too low.

Check the V/f characteristics.

The Inverter capacity is too low.

Replace the Inverter with one that

has a larger capacity.

Overtorque Detected 1

There has been a torque higher than

the setting in L6-02 for longer than the

time in L6-03.

–

• Make sure that the settings in

L6-02 and L6-03 are appropri-

ate.

• Check the mechanical system

and correct the cause of the

overtorque.

High-slip Braking OL

The output frequency did not change

for longer than the time set in N3-04.

The inertia of the connected machine

is too large.

Make sure the load is an inertial

load.

Undertorque Detected 1

There has been a torque lower than the

setting in L6-02 for longer than the

time in L6-03.

–

• Make sure that the settings in

L6-02 and L6-03 are appropri-

ate.

• Check the mechanical system

and correct the cause of the

undertorque.

PI Feedback Lost

A PI feedback loss detection is

enabled (b5-12 ≠ 0) and the PI feed-

back input was less than b5-13 (PI

feedback loss detection level) for

longer than the time set in b5-14 (PI

feedback loss detection time).

–

• Check the PI feedback signal

source for correct operation.

• Check the wiring.

External fault input from Communi-

cations Option Card

–

Check the Communications

Option Card and communications

signals.

Table 7.1 Fault Displays and Processing (Continued)

Display Meaning Probable Causes Corrective Actions

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Loading...

Loading...