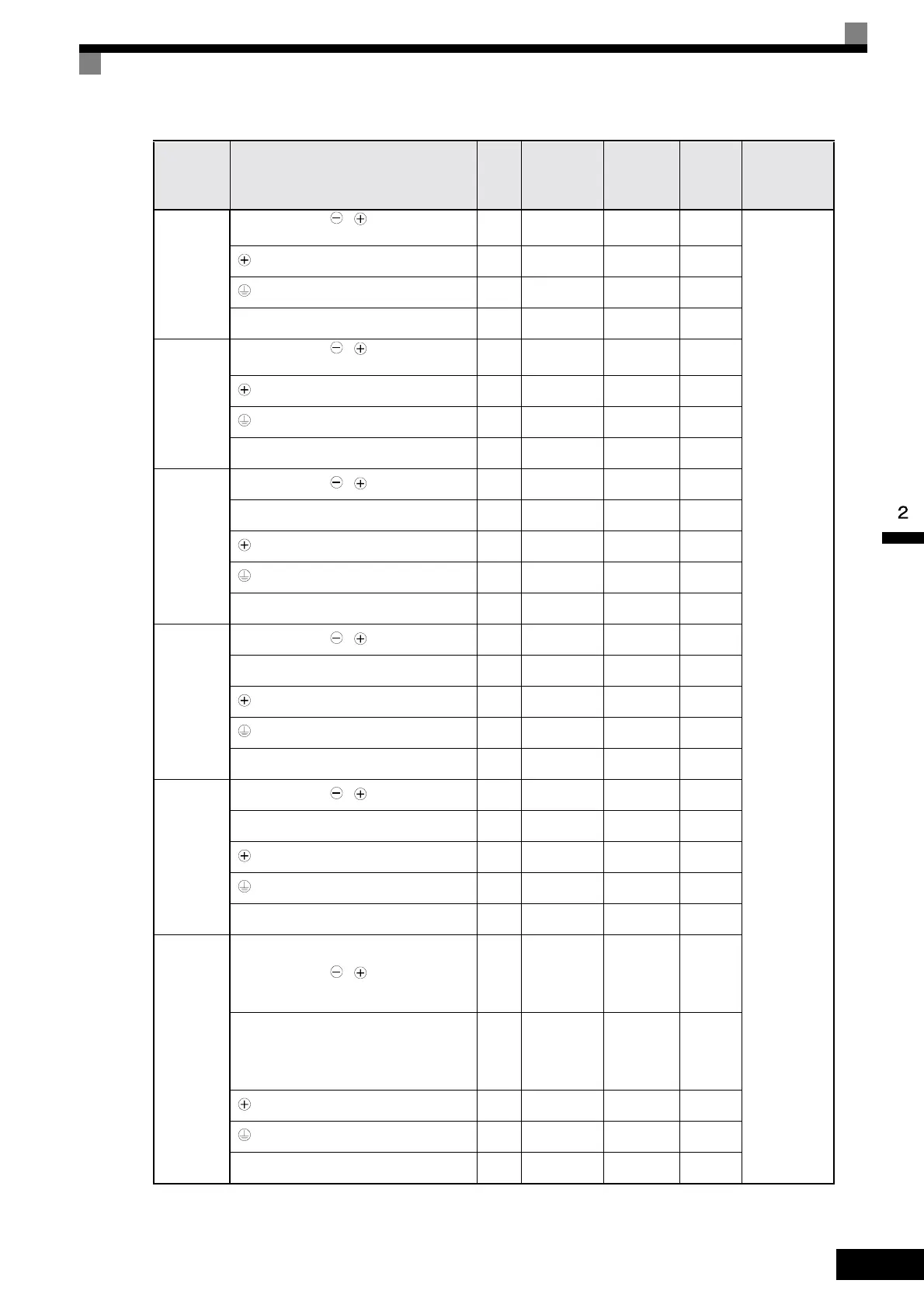

Wiring Main Circuit Terminals

2-7

* The wire thickness is set for copper wires at 75°C

E7C2037

R/L1, S/L2, T/L3, , 1 U/T1,

V/T2, W/T3, R1/L11, S1/L21, T1/L31

M10 17.6 to 22.5

60 to 100

(2/0 to 4/0)

60

(2/0)

Power cables,

e.g., 600 V vinyl

power cables

3

M8 8.8 to 10.8

5.5 to 22

(10 to 4)

–

M10 17.6 to 22.5

30 to 60

(2 to 2/0)

30

(2)

r/l1, ∆/l2 M4 1.3 to 1.4

0.5 to 5.5

(20 to 10)

1.25

(16)

E7C2045

R/L1, S/L2, T/L3, , 1 U/T1,

V/T2, W/T3, R1/L11, S1/L21, T1/L31

M10 17.6 to 22.5

80 to 100

(3/0 to 4/0)

80

(3/0)

3

M8 8.8 to 10.8

5.5 to 22

(10 to 4)

–

M10 17.6 to 22.5

38 to 60

(1 to 2/0)

38

(1)

r/l1,

∆/l2 M4 1.3 to 1.4

0.5 to 5.5

(20 to 10)

1.25

(16)

E7C2055

R/L1, S/L2, T/L3, , 1

M12 31.4 to 39.2

50 to 100

(1/0 to 4/0)

50 × 2P

(1/0 × 2P)

U/T1, V/T2, W/T3, R1/L11, S1/L21, T1/L31 M10 17.6 to 22.5

100

(4/0)

100

(4/0)

3

M8 8.8 to 10.8

5.5 to 60

(10 to 2/0)

–

M10 17.6 to 22.5

30 to 60

(3 to 4/0)

50

(1/0)

r/l1,

∆/l2 M4 1.3 to 1.4

0.5 to 5.5

(20 to 10)

1.25

(16)

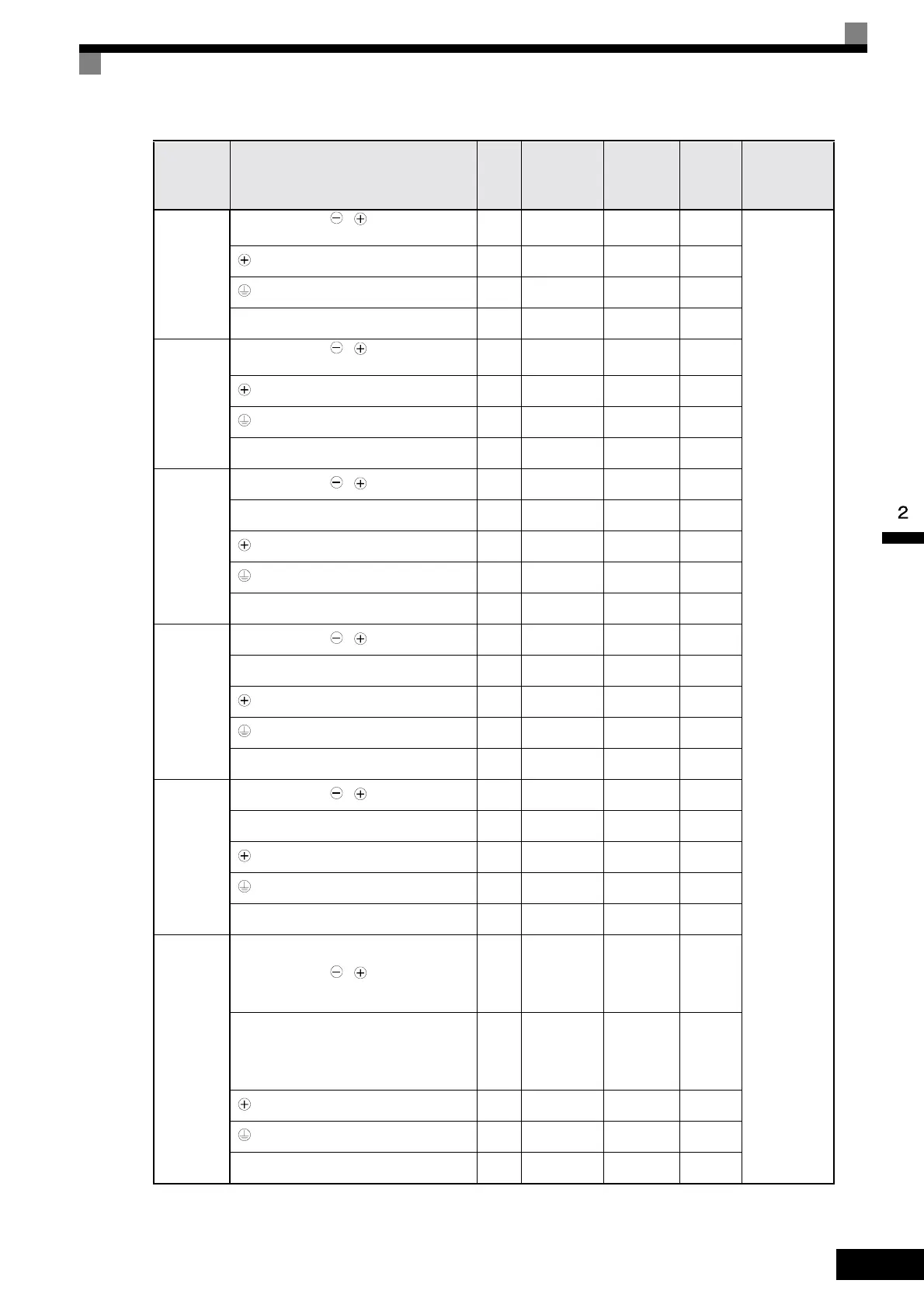

E7C2075

R/L1, S/L2, T/L3, , 1

M12 31.4 to 39.2

80 to 125

(3/0 to 250)

80 × 2P

(3/0 × 2P)

U/T1, V/T2, W/T3, R1/L11, S1/L21, T1/L31 M10 17.6 to 22.5

80 to 100

(3/0 to 4/0)

80 × 2P

(3/0 × 2P)

3

M8 8.8 to 10.8

5.5 to 60

(10 to 2/0)

–

M10 17.6 to 22.5

100 to 200

(3/0 to 400)

100

(3/0)

r/l1,

∆/l2 M4 1.3 to 1.4

0.5 to 5.5

(20 to 10)

1.25

(16)

E7C2090

R/L1, S/L2, T/L3, , 1

M12 31.4 to 39.2

150 to 200

(250 to 400)

150 × 2P

(250 × 2P)

U/T1, V/T2, W/T3, R1/L11, S1/L21, T1/L31 M12 31.4 to 39.2

100 to 150

(4/0 to 300)

100 × 2P

(4/0 × 2P)

3

M8 8.8 to 10.8

5.5 to 60

(10 to 2/0)

–

M12 31.4 to 39.2

60 to 150

(2/0 to 300)

60 × 2P

(2/0 × 2P)

r/l1,

∆/l2 M4 1.3 to 1.4

0.5 to 5.5

(20 to 10)

1.25

(16)

E7C2110

R/L1, S/L2, T/L3, , 1

M12 31.4 to 39.2

200 to 325

(350 to 600)

200 × 2P,

or 50 × 4P

(350 × 2P,

or 1/0 ×

2P)

U/T1, V/T2, W/T3, R1/L11, S1/L21, T1/L31 M12 31.4 to 39.2

150 to 325

(300 to 600)

150 × 2P,

or 50 × 4P

(300 × 2P,

or 1/0 ×

4P)

3

M8 8.8 to 10.8

5.5 to 60

(10 to 2/0)

–

M12 31.4 to 39.2

150

(300)

150 × 2P

(300 × 2P)

r/l1,

∆/l2 M4 1.3 to 1.4

0.5 to 5.5

(20 to 10)

1.25

(16)

Inverter

Model

CIMR-

Terminal Symbol

Ter mi-

nal

Screws

Tightening

Torque

(N•m)

Possible

Wire Sizes

mm

2

(AWG)

Recom-

mended

Wire Size

mm

2

(AWG)

Wire Type

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Loading...

Loading...