5

-42

* When the control method is changed, the factory setting will change. The flux vector factory setting is given.

Analog Reference Board: F2

User constants for the Analog Reference Board are shown in the following table.

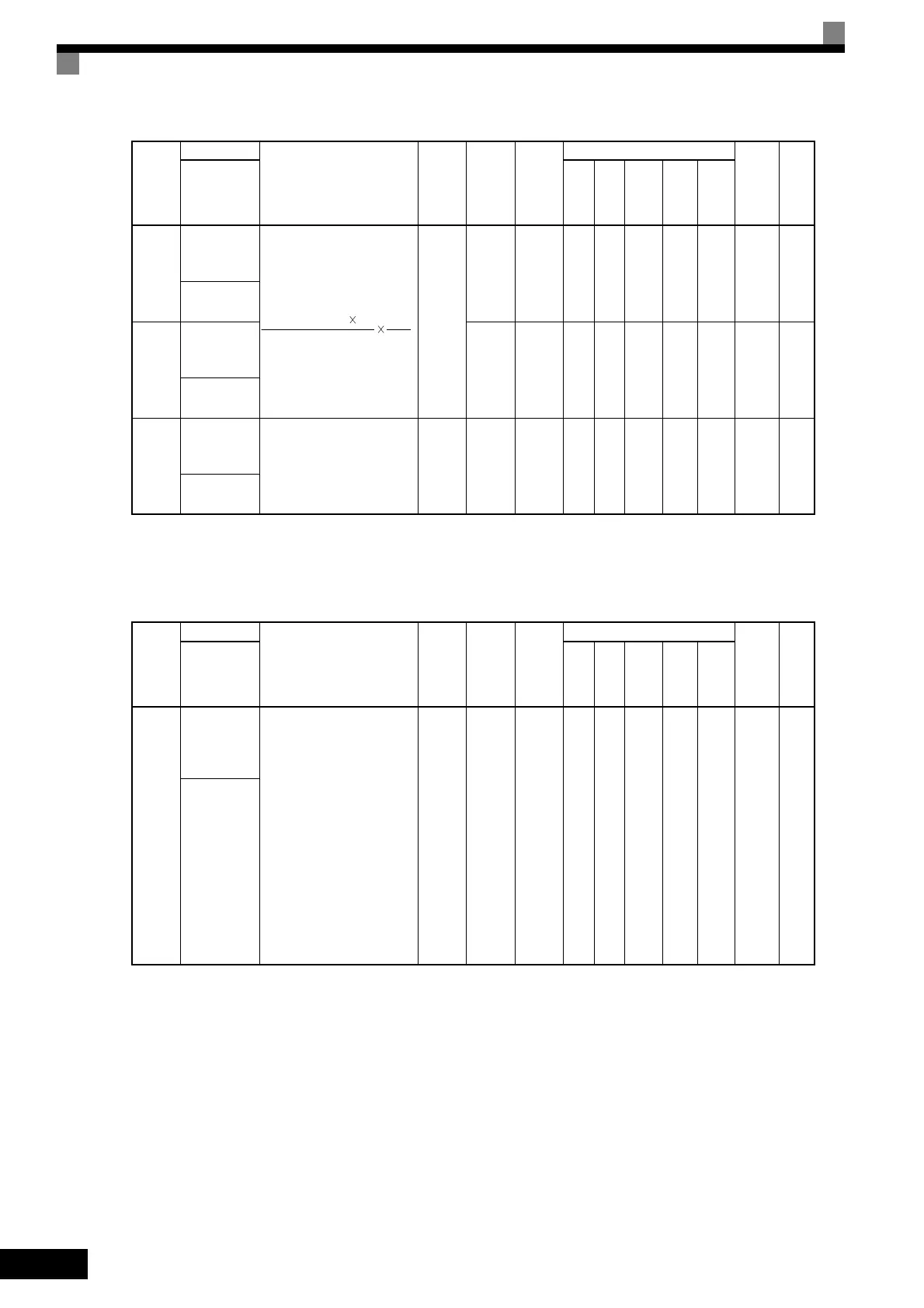

F1-12

Number of

PG gear teeth

1

Sets the number of teeth on

the gears if there are gears

between the PG and the

motor.

A gear ratio of 1 will be used

if either of F1-12 or F1-13

constant is set to 0.

0 to

1000

0 No No A No No No 38BH

6-161

PG # Gear

Teeth1

F1-13

Number of

PG gear teeth

2

0 No No A No No No 38CH

6-161

PG # Gear

Teeth2

F1-14

PG open-cir-

cuit detection

time

Used to set the PG disconnec-

tion detection time. PGO will

be detected if the detection

time continues beyond the set

time.

0.0 to

10.0

2.0 s No No A No A No 38DH

6-161

PGO Detect

Time

Con-

stant

Number

Name

Description

Setting

Range

Factory

Setting

Change

during

Opera-

tion

Control Methods

MEMO-

BUS

Regis-

ter

Page

Display

V/f

V/f

with

PG

Open

Loop

Vec-

tor

1

Flux

Vec-

tor

Open

Loop

Vec-

tor

2

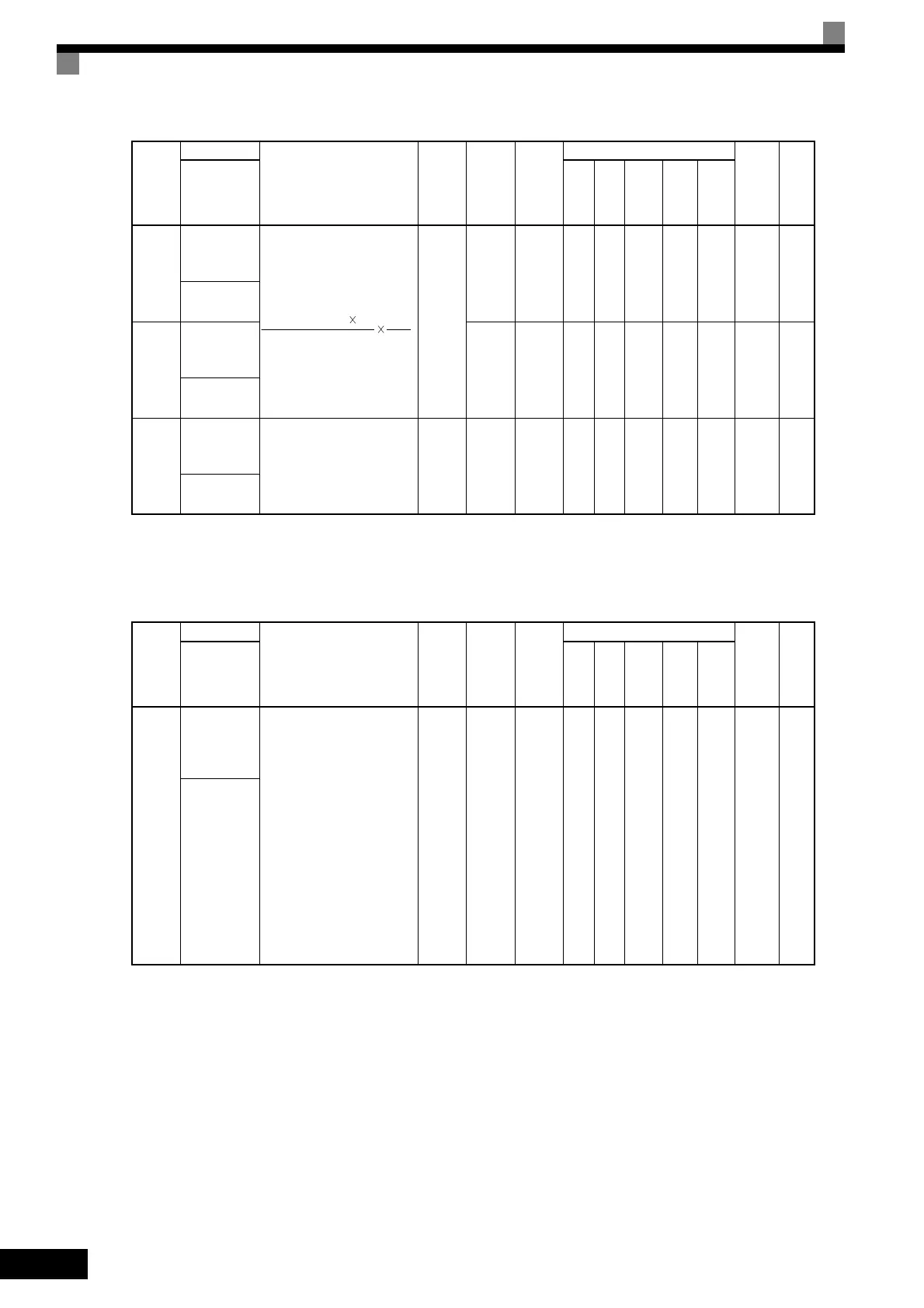

F2-01

Bi-polar or

uni-polar

input selec-

tion

Sets the functions for channel

1 to 3 which are effective

when the AI-14B Analog

Reference Board is used.

0: 3-channel individual

(Channel 1: terminal A1,

Channel 2: terminal A2,

Channel 3: terminal A3)

1: 3-channel addition (Addi-

tion values are the fre-

quency reference)

When set to 0, select 1 for b1-

01. In this case the multi-

function input “Option/

Inverter selection” cannot be

used.

0 or 1 0 No A A A A A 38FH

6-167

AI-14 Input

Sel

Con-

stant

Number

Name

Description

Setting

Range

Factory

Setting

Change

during

Opera-

tion

Control Methods

MEMO-

BUS

Regis-

ter

Page

Display

V/f

V/f

with

PG

Open

Loop

Vec-

tor

1

Flux

Vec-

tor

Open

Loop

Vec-

tor

2

Input pulses from PG 60 F1-13

F1-01 F1-12

TOE-S616-60.1.book 42 ページ 2017年8月4日 金曜日 午後3時41分

Loading...

Loading...