B2-16

IM 34M06H62-02E 2nd Edition : June 2008-00

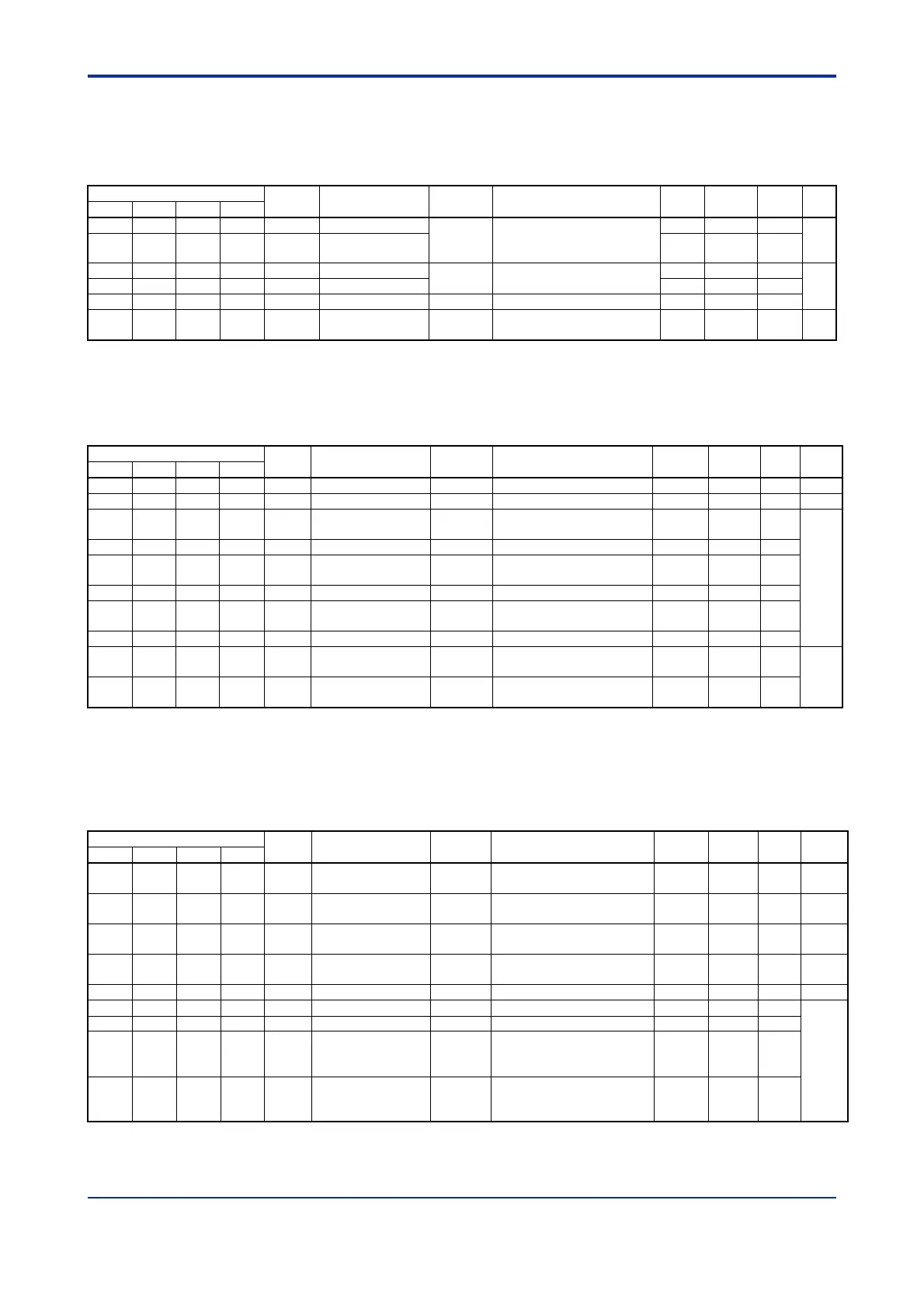

SP-related Function Settings

Use these parameters to define set points for individual loops, as required. They can be

used for setting upper and lower input limits, rate-of-change, and tracking.

Table B2.19 SP-related Function Settings

Data Position Number

Symbol Description Unit

Data Range

Default

Value

Attribute Stored

See

Also

Loop 1 Loop 2 Loop 3 Loop 4

164 364 564 764 SPH Upper SP limit

Industrial

PRL to PRH if SPL < SPH

CSP is fixed at SPL if SPL

SPH

PRH RW

C4.3

165 365 565 765 SPL Lower SP limit PRL RW

166 366 566 766 SPR.UP SP up gradient

Industrial

0 to (PRH-PRL)

0: SP gradient disabled

0 RW

C4.4167 367 567 767 SPR.DN SP down gradient 0 RW

168 368 568 768 SPR.TM Gradient time unit None 0: Hour, 1: Minute 0 RW

169 369 569 769 SP.TR SP tracking mode None

0: Tracking enabled

1: Tracking disabled

1 RW C4.6

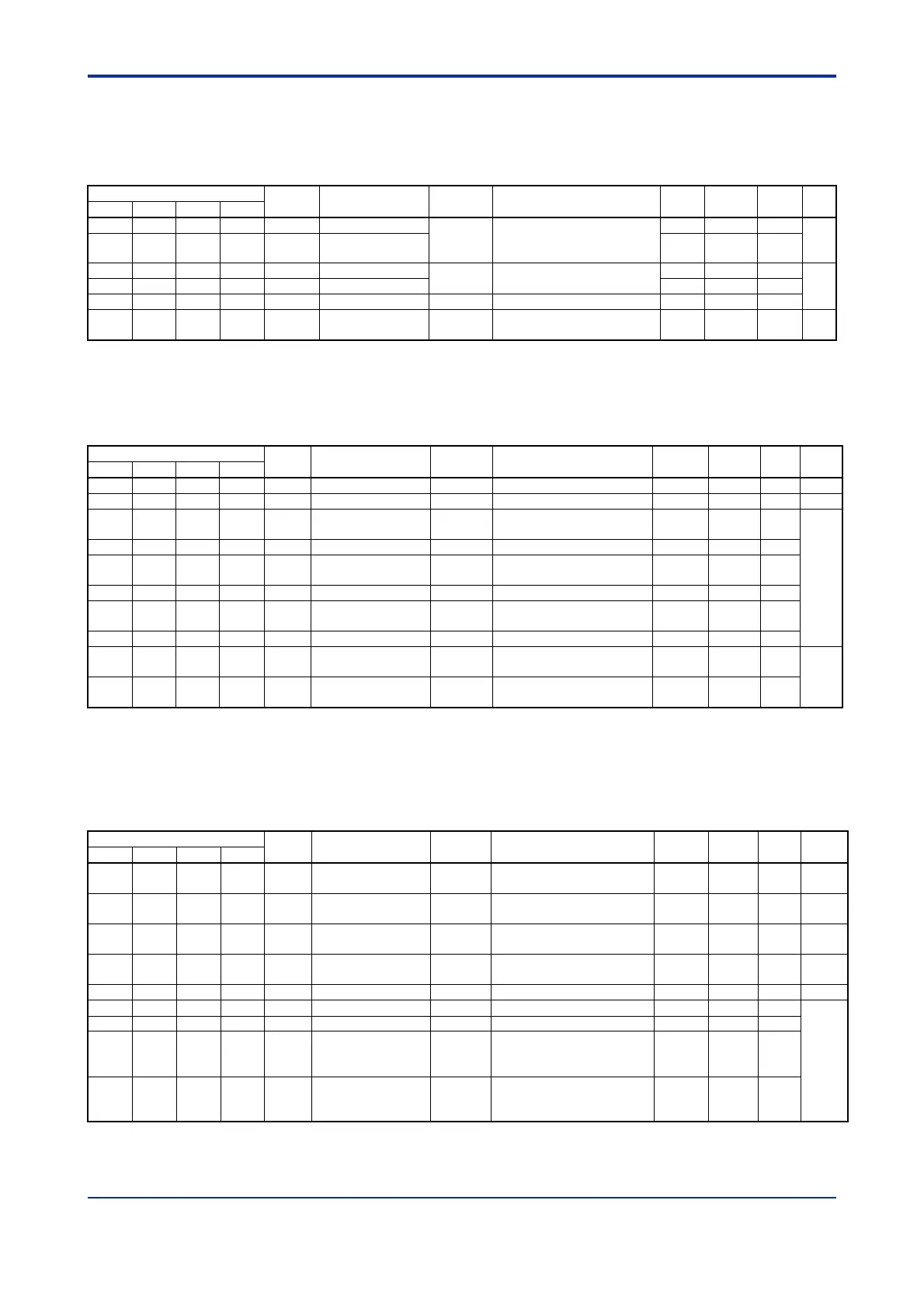

PV-related Function Settings

Use these parameters to perform PV-related setup for individual loops, as required. They

can be used for configuring PV correction, square root extraction and input filtering.

Table B2.20 PV-related Function Settings

Data Position Number

Symbol Description Unit Data Range

Default

Value

Attribute Stored

See

Also

Loop 1 Loop 2 Loop 3 Loop 4

171 371 571 771 BS Fixed bias Industrial -(SH-SL) to (SH-SL) 0 RW C3.8

172 372 572 772 FL Input filter Seconds 0: OFF, 1 to 120 seconds 0 RW C3.10

173 373 573 773 X1 Broken-line input 1 Industrial

-5.0% to 105.0% of (SL to

SH)

SL RW

C3.7

174 374 574 774 Y1 Broken-line bias 1 Industrial -(SH-SL) to (SH-SL) 0 RW

175 375 575 775 X2 Broken-line input 2 Industrial

-5.0% to 105.0% of

(SL to SH)

SL RW

176 376 576 776 Y2 Broken-line bias 2 Industrial -(SH-SL) to (SH-SL) 0 RW

177 377 577 777 X3 Broken-line input 3 Industrial

-5.0% to 105.0% of

(SL to SH)

SL RW

178 378 578 778 Y3 Broken-line bias 3 Industrial -(SH-SL) to (SH-SL) 0 RW

179 379 579 779 SR

Square root

extraction

None 0: OFF; 1: ON 0 RW

C3.9

180 380 580 780 LC Low cut Industrial 0.0 to 5.0% of (SH-SL))

1.0% of

(SH -SL)

RW

Operation-related Function Settings

Use these parameters to configure control operation for individual loops, as required.

They can be used to set up dynamic auto-tuning, the “super” function, control mode, and

other control operation-related functions.

Table B2.21 Operation-related Function Settings

Data Position Number

Symbol Description Unit Data Range

Default

Value

Attribute

Stored

See

Also

Loop 1 Loop 2 Loop 3 Loop 4

181 381 581 781 SELF

Dynamic

auto-tuning enable

None 0: Disabled, 1: Enabled 0 RW C5.1

182 382 582 782 SC

"Super" enable

code

None 0: Disabled, 1: Enabled 0 RW C6.7

183 383 583 783 ARW ARW setting %

0: Automatic, 500 to 2000:

(50.0 to 200.0%)

0 RW C6.8

184 384 584 784 CMD Control mode None

0: Standard PID control

1: Fixed-point control

0 RW C6.6

185 385 585 785 ZONE Zone PID selection None 0: Disabled, 1: Enabled 0 RW C6.9

186 386 586 786 1RP Reference point 1 Industrial PRL to PRH PRL RW

C6.9.2

187 387 587 787 2RP Reference point 2 Industrial PRL to PRH PRL RW

188 388 588 788 RHY

Zone switching

hysteresis

Industrial 0 to (PRH-PRL)

(PRH -

PRL) x

0.5%

RW

189 389 589 789 RDV

Reference

deviation

Industrial

0 to (PRH-PRL)

0: Reference deviation

disabled

0 RW

Loading...

Loading...