1. Overview

26

TI 11B08A01-01E

• Externalsampleconditioningequipment

• Personal computer

• Computerforuppersystem,Analogequipment

• Analyzer network system

Thesystemcongurationmaydifferaccordingtothespecications.

SeetheGeneralSpecicationsfordetails.

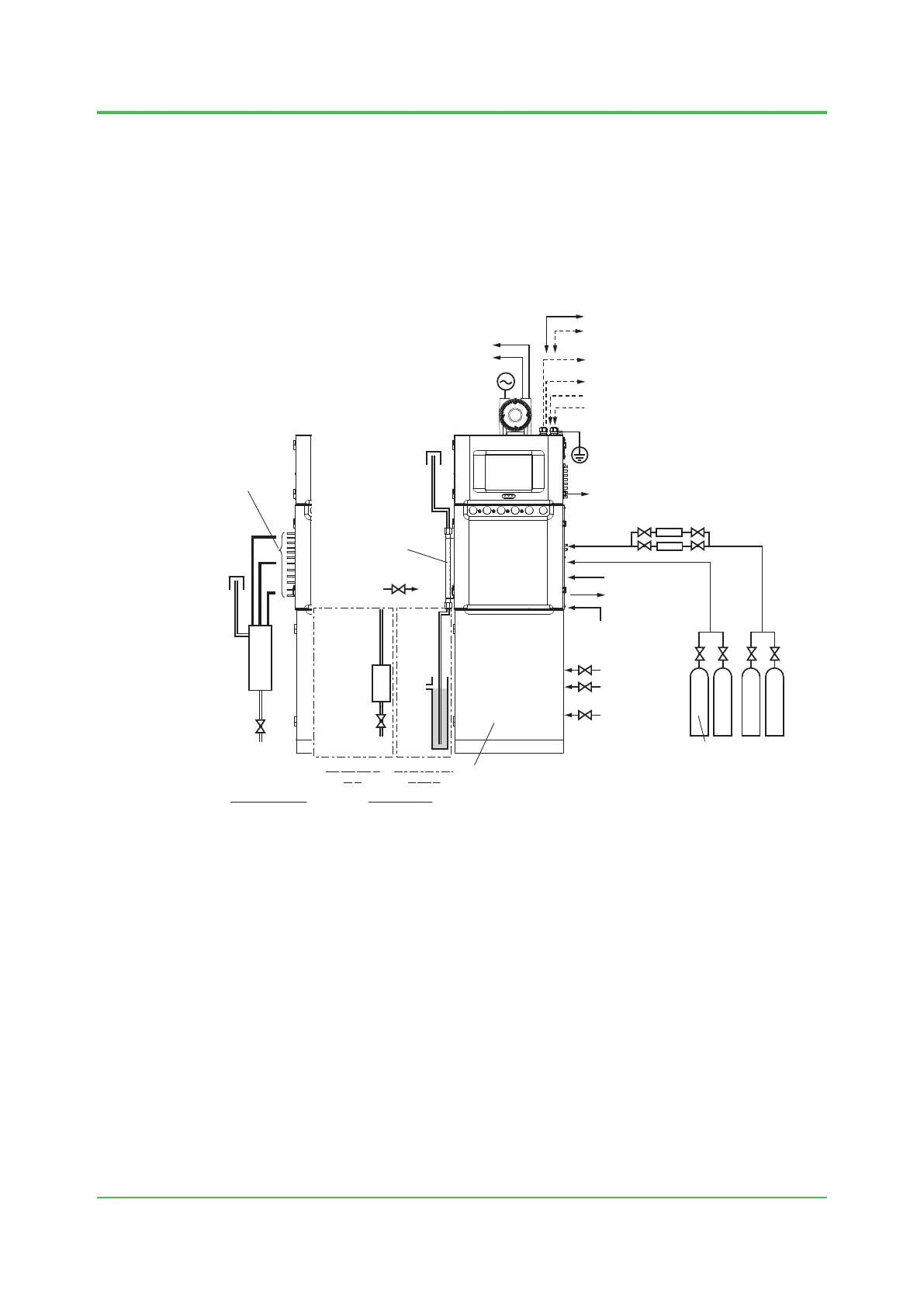

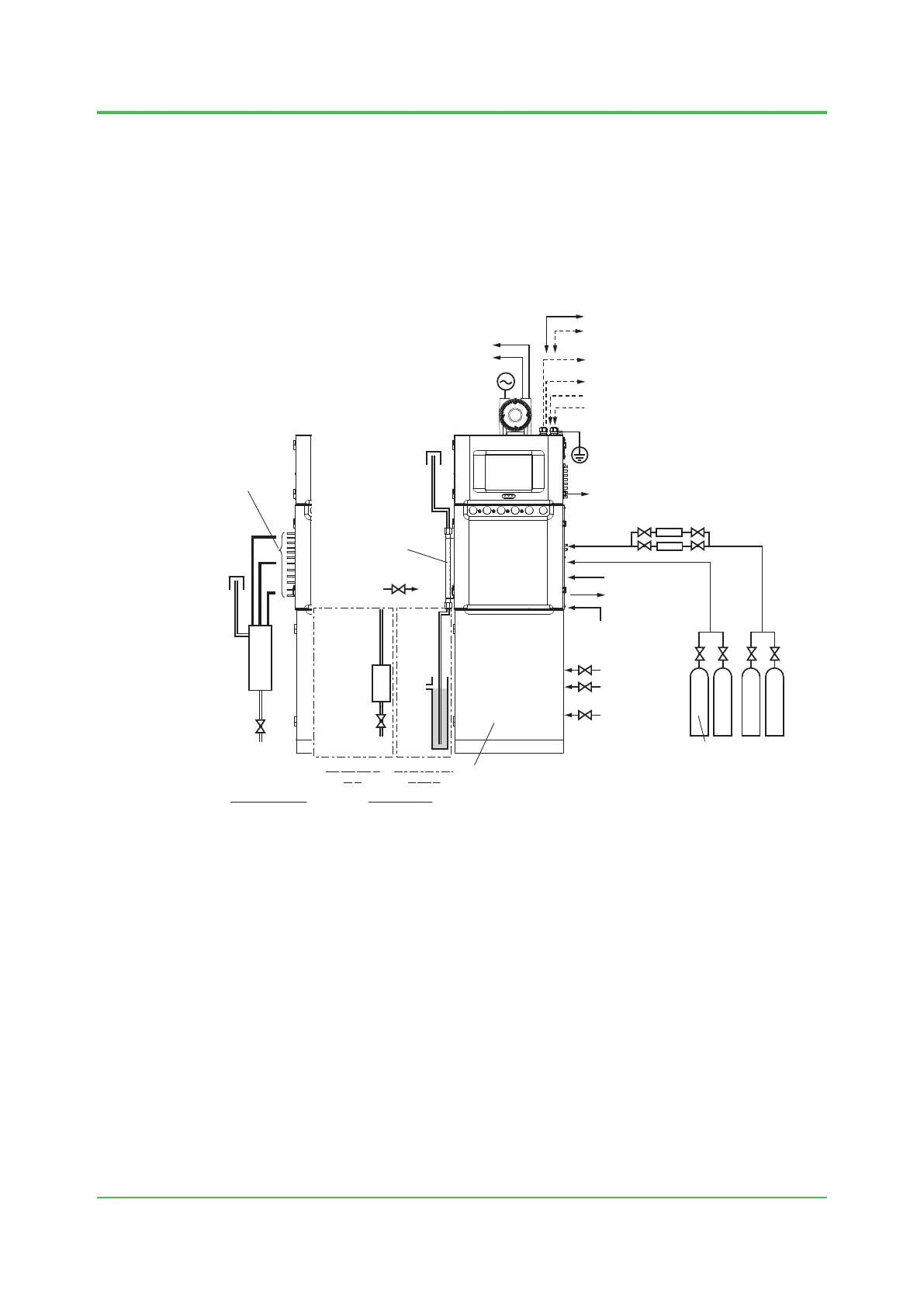

1.1 Wiring and Piping Diagram

Vent line

(1/8 inch 316SS pipes

for standard,

1/4 inch teflon tube

for FID/FPD)

Without Vent stack

50A

SGP, STPG

15A SPG, STPG

Vent stack

50A

SGP, STPG

15A

SPG,

STPG

Vent stack

ID:10mm

or more

Vent header

(Both ends are

Rc1/2 or 1/2NPT)

Liquid sample

50A

Water

seal

pot

15A SPG, STPG

Drain

*7

Drain tank

*4 *6

Analyzer base

sampling unit

(Depends on specifications)

Calibration standard

sample

Dehumidifier

Combustion air for FID/FPD

(400 to 700 kPa)

Instrument air

(350 to 900kPa)

(500 to 900 kPa for FPD)

(Spare)

(Spare)

Carrier gas

Grounding resistance 100Ω or less

Ethernet communication *10

Power

Serial communication (RS-422) *10

Analog input (4 to 20mA/1 to 5V DC), up to 16 *10

Contact input (5V DC, 20mA DC or more), up to 32

Analog output (4 to 20mA DC)

Channel isolation or System isolation, up to 32

Contact output (AC or DC), up to 20 *10

Air output for Stream switching valve

(350 kPa), up to 8

Air output for

Atmospheric balance

valve (350 kPa)

Contact output for System alarm 1

Contact output for Annunciator

*1

*2

*8

*5

*9

*3

*11

*4

*4

Combustion gas or

Make-up gas for FID/FPD

With Vent stack

Sample

…

Sample

Using a water

seal pot

Using a drain

tank

*1: ThespecicationdeterminesthenumberofExplosionproofenclosures.NoenclosuresisneededforFM-Y,

CSA-Y type.

*2: Ifananalyzerbasesamplingunitisprovided,mostapplicationsrequirenoexternalsamplingequipment.

In addition, optimum sampling systems are prepared depending on various conditions. (For details, consult

Yokogawa. Optimal sampling systems will be offered.)

*3: Forairpurgepiping,usestainlesssteelpipeof1/2inchormore.

*4: Powerandcontactoutputforsystemalarm1orannunciatorareconnectedtocontrolunitincaseofFM-Y,

CSA-Y type.

*5: DehumidiercanbeoptionallyprovidedbyYokogawa.Otherwiringcables,pipingandinstallationmaterials

should be supplied by the user.

*6: Circuitbreaker(30ATorless)shallbesuitablefortheitemofthepowersupplydescribedinthe

specication,andlocatedneartheanalyzer.

*7: DraintankisneededonlyforGCsusingFID/FPD.ThisisnotusedforGCsusingTCD.

*8: Fixventingpipesproperlysothattheloadoftheventingpipesdoesnotapplytotheassemblingventsof

this analyzer.

*9: Thenumberofstreamsincludingoneforcalibrationstandardsampleisasfollows,incaseofusingGCSMP.

Type 1: Maximum of 7

Type 2, 4: Maximum of 4

*10: Signalinterrupters(disconnecters)arerequireddependingonthespecication.

*11: Airpressuresetvalueoftheregulatorisdependedonthesourceairtemperatureandneedtotunethe

setting value.

600kPaisrequiredwhenambientorinstrument-airtemperatureishigherthan46°C(1FPD)or40°C(2FPDs).

Sep. 07, 2017-00

Loading...

Loading...