2. Installation, Piping, and Wiring

63

TI 11B08A01-01E

(a) Sample inlet pipes

These are pipes to lead samples from process lines or an external sampling system into analyzer

STREAMS #1 to #12 or the sample inlet of the pressure control section.

The analyzer can analyze up to 31 sample streams. For more than 31 sample streams, an

external sampling system is employed, which has a stream switching function. In this case, one

sample inlet pipe is used to lead multiple samples into the analyzer. When providing more than

onepipe,seethe“OperationData”sothatthespeciedsamplecanowintotheanalyzerfrom

the designated inlet port. STREAM and No. are marked at the piping port.

Use stainless steel of O.D. 6 mm or 1/4 inch with any oil cleaned off.

(b) Standard sample inlet pipes

These are pipes between the outlets of pressure regulators for standard gas cylinders and

STANDARD #1 to #3 ports of the analyzer.

When different standard gases are used, provide separate pipes for each gas to lead them into

the analyzer.

Use stainless steel of O.D. 6 mm or 1/4 inch with any oil cleaned off.

(c) Carrier gas inlet pipes

These are pipes to introduce the carrier gas to the analyzer between the outlets of carrier gas

cylinder pressure regulators and CARRIER IN ports of the analyzer.

When two different carrier gases are used, provide separate pipes for each gas to lead them into

the analyzer.

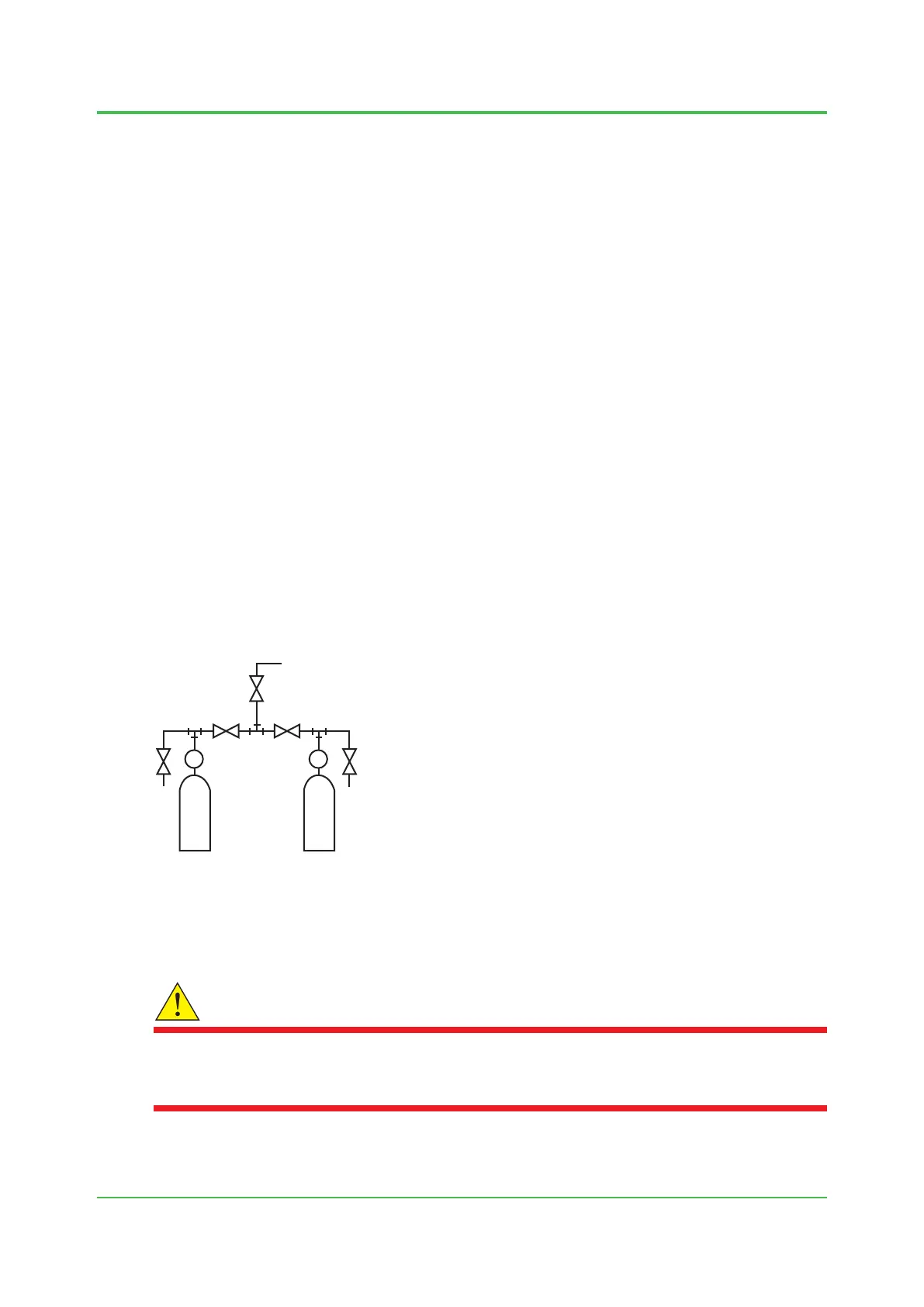

The following is recommended. By arranging the two gas cylinders in this way, there is no

contamination of air.

(Spare)

Figure 2.10

Conrmthattheinsidesofthepipesandpipettingsarenotcontaminated.

Conrmthatthepipingconnectionsaredonewithnoleakage.

WARNING

Thefollowingexplosionproofrequirementsmustbesatisedforhydrogengas.

• Noleakage

• Supplyhydrogengastotheanalyzerat500±20kPa.

Sep. 07, 2017-00

Loading...

Loading...