II K 6-27

Operating Instructions

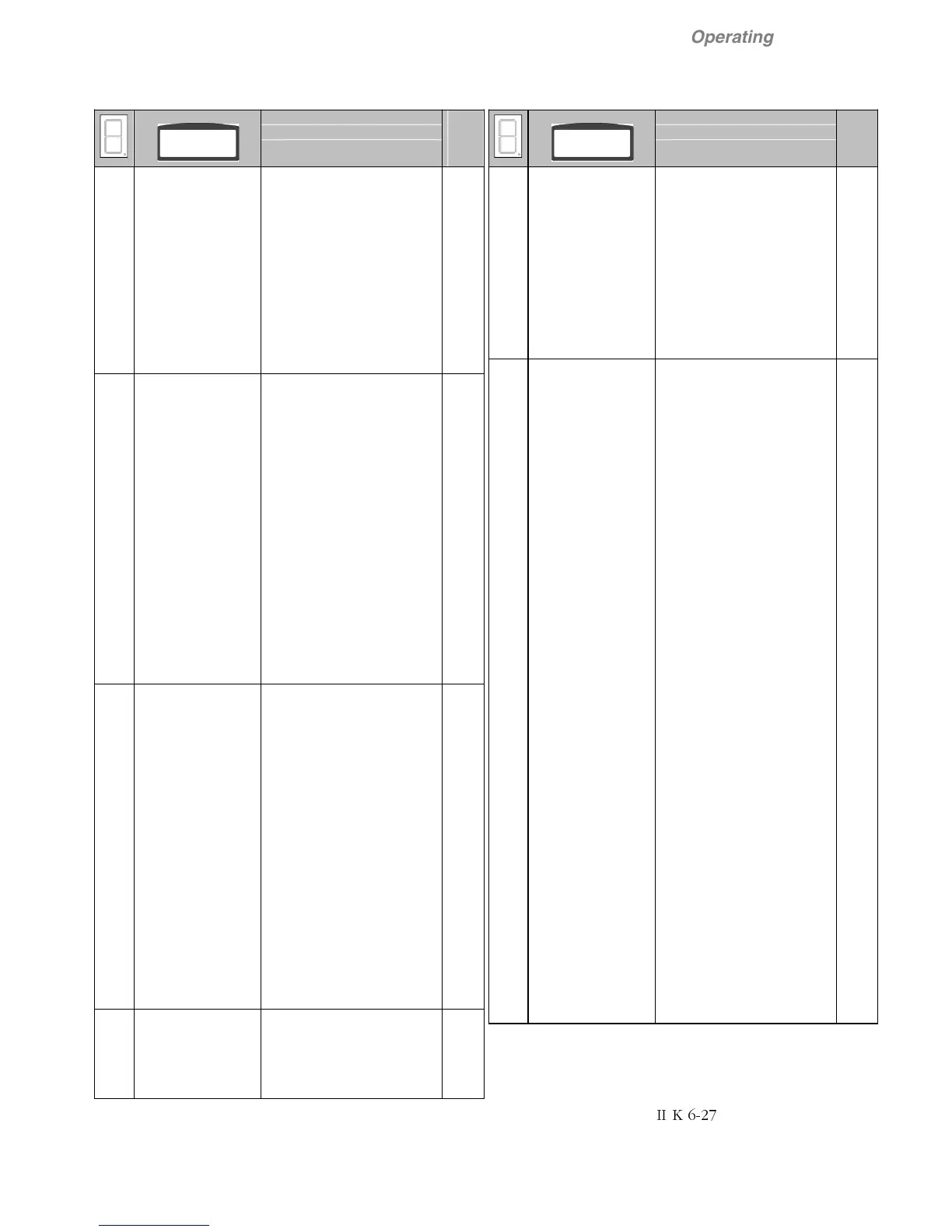

Fault message

Fault no.

Definition /

Possible source

Param.

F 7 Converter Overtemp

see also A4

Converter Over Temperature

Temperature of the converter too

high.

Please wait until the temperature

of the converter has cooled

down. After that you can clear

the fault by pressing the Reset

button on the control panel.

Please check:

• fan supply

• fan components

• air inlet

• ambient temperature

• load cycle too high?

7.09

bit 6

F 8 Motor Overtemp

see also A5

Motor Over Temperature

Temperature of the motor too

high (if PTC resistor connected

to AI2).

Please wait until the motor has

cooled down. If you have any

digital output assigned to „Fan

On“ this output will be energized

until the temperature drops be-

low the alarm level. After that

you can clear the fault by pres-

sing the Reset button on control

panel.

Please check

• temperature sensor and its

cabling

• motor cooling

fan supply

direction of rotation

filter

• load cycle too high?

7.09

bit 7

F 9 Mains Undervoltage

see also A2

see also A8

Mains Undervoltage

Parameter Arm Volt Nom (1.02)

has to be in accordance to the

Main Supply Voltage, see ma-

nual chapter 2.2 table 2.2/4.

Otherwise a fault F09-Mains

Undervoltage (latest 10 sec

after ON command) or an alarm

A02-Mains Voltage Low (im-

mediately after ON command)

will occurs. During the Commis-

sioning Wizard that can happen

at any step when the drive is

switched on [Start Drive , Press

(I)]. To avoid fault F09-Mains

Undervoltage or alarm A02-

Mains Voltage Low set para-

meter Net Underv Trip (1.10) =

0…-10% before starting the

Commissioning Wizard again.

Refer also manual chapter 4.5.1

Monitoring the Mains Voltage.

7.09

bit 8

F 10 Mains Overvoltage

Mains Overvoltage

The mains voltage is higher than

120% of the rated converter

voltage. This limit is fixed.

Please switch off the drive and

measure the mains voltage.

7.09

bit 9

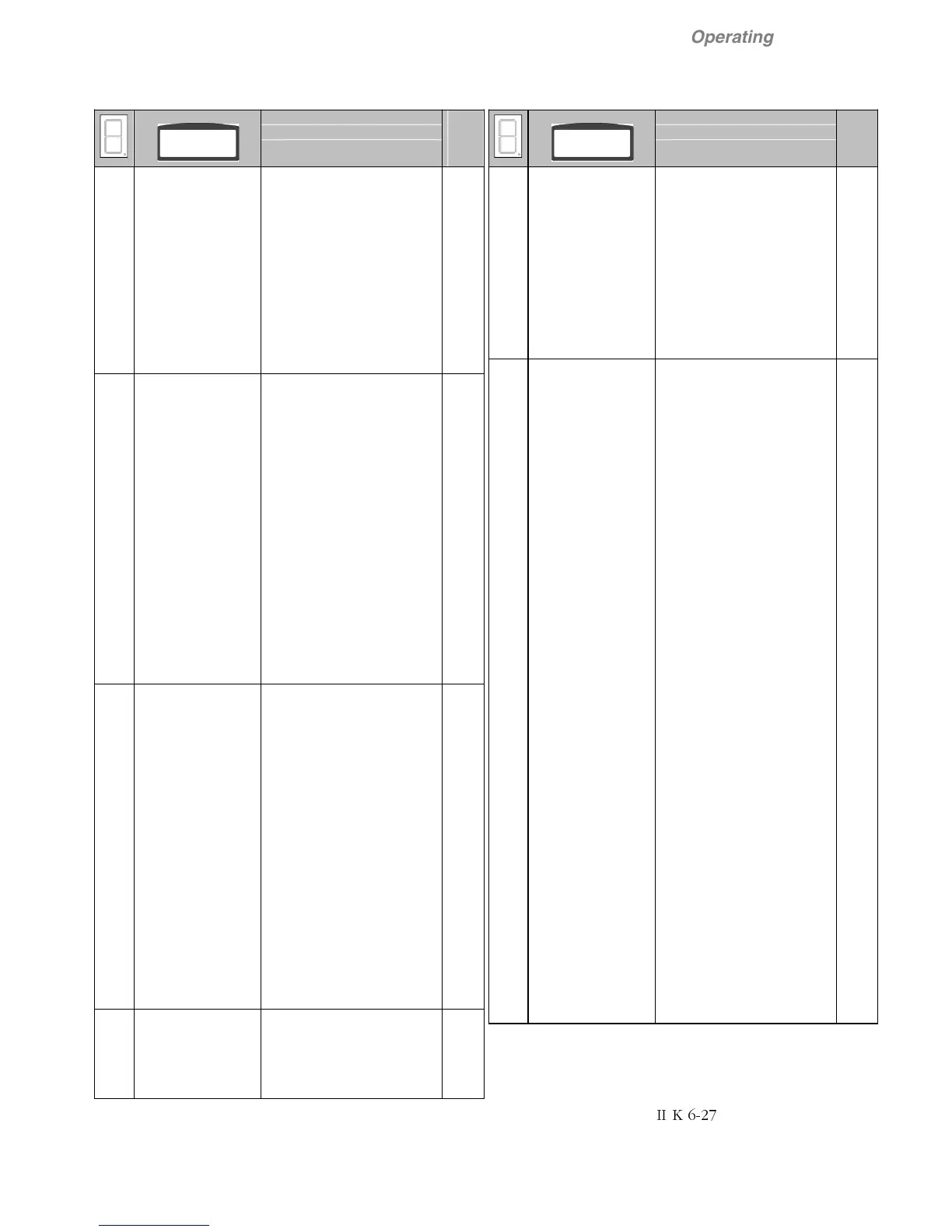

Fault message

Fault no.

Definition /

Possible source

Param.

F 11 Mains Sync Fault

see also A8

Mains Synchronization Fault

The synchronization to the mains

frequency has been lost during

operation.

Possible problems causes:

• Problems with the connec-

tion of the cable or with the

main contactor

• Blown fuses

• Mains frequency out of ran-

ge (47...63 Hz)

• Mains frequency not stable

or varying too fast

7.09

bit 10

F 12 Field Undercurrent

see also A8

Field Undercurrent

• If field weakening is needed

find out the minimum field

current at maximum field

weakening point (usually

written at motor name plate).

During Commissioning Wi-

zard set parameter Field

Low Trip (4.06) = 10% less

than minimum field current.

Otherwise could be F12-

Field Undercurrent occurs

during field weakening ope-

ration.

• It’s also possible that this is

a sequential fault of Mains

Undervoltage (F9 / A2).

Read the faultlogger to see

the fault history. DCS400 is

using a new method to mo-

nitor the mains voltage.

Could be Armature Voltage

Nominal and Mains Voltage

Actual doesn’ t corresponds

to each other. Correct it in

accordance to manual

chapter 2.2 - table 2.2/4 or

adapt parameter Net Underv

Trip (1.10) to a lower value.

• Depend on motor Field

Autotuning has detected a

very high Field Cur KP

(4.03) factor. That can result

in field current oscillation and

drive can trip either due to

field current overshoots F13-

Field Overcurrent or field

current undershoots F12-

Field Undercurrent. Set pa-

rameter Field Cur KP (4.03)

to a lower value and / or

Field Cur TI (4.04) to a

higher value. Try with default

values of these two pa-

rameters.

7.09

bit 11

Loading...

Loading...