II K 4-52

Overview of Software

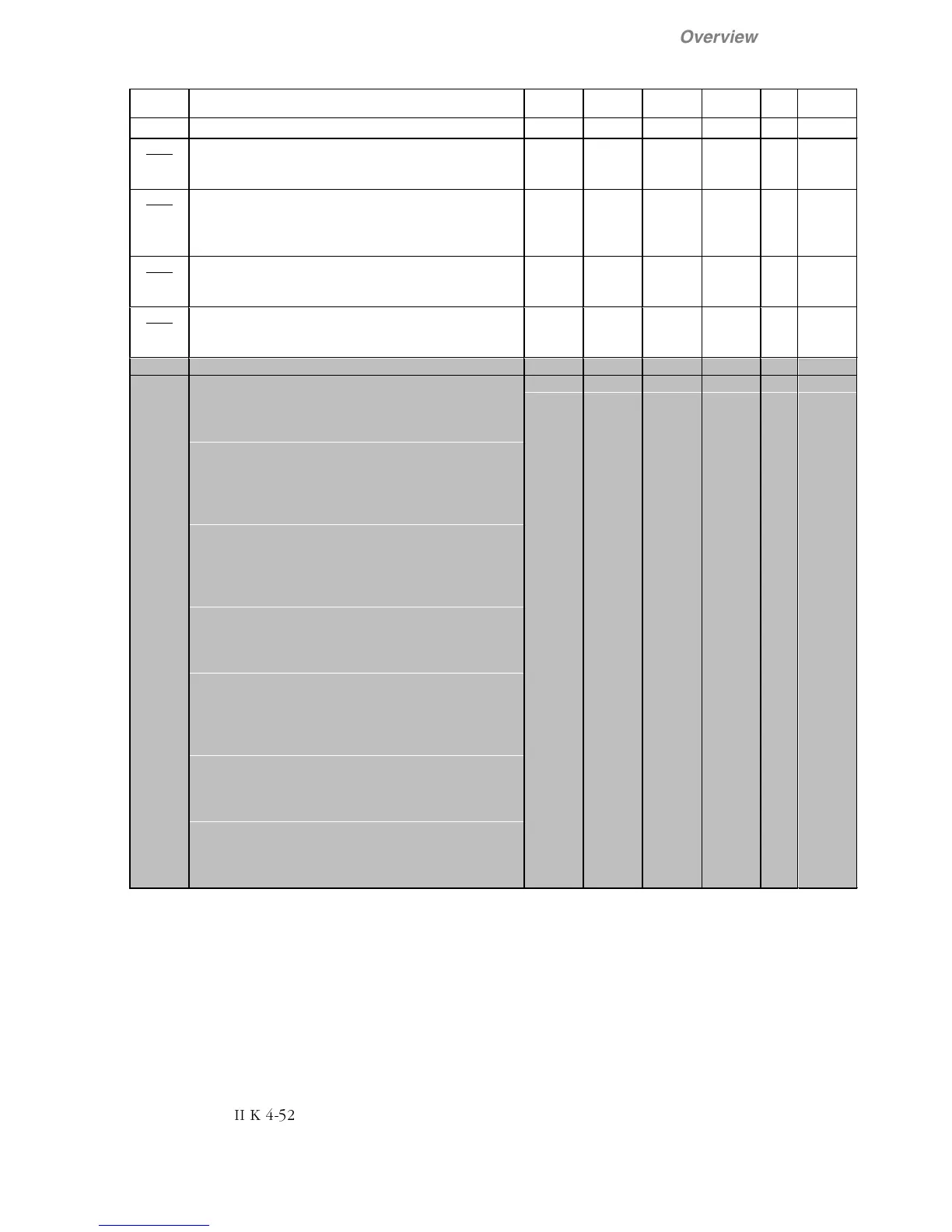

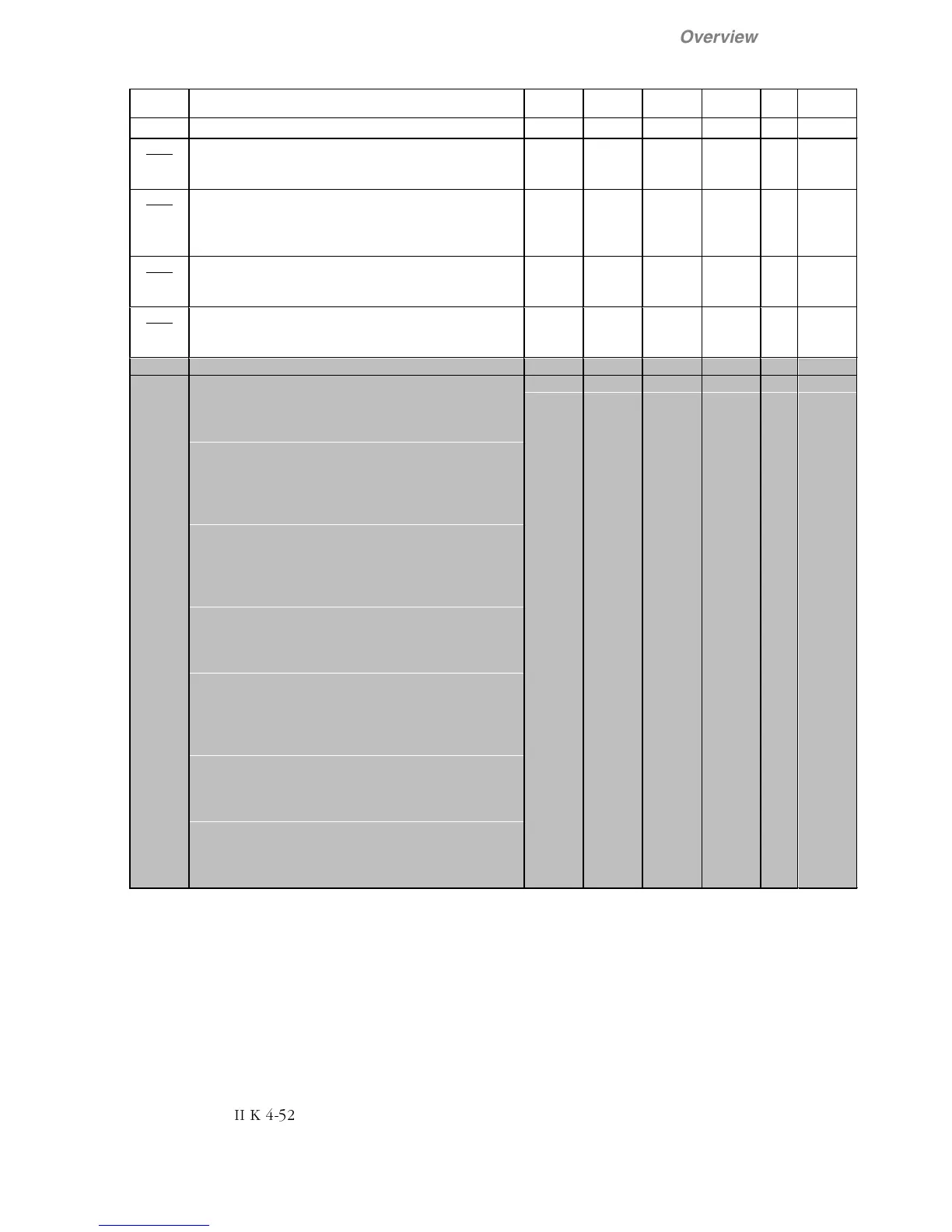

ParNo. Parameter name and significance Min Max Default Unit (1)

custom.

setting

Grp 3 Armature (continued)

3.10

auto-

tuning

Arm Cur Reg TI

Integration time constant of the armature current

controller (PI controller) in milliseconds.

0.0 1000.0 50.0 ms

3.11

auto-

tuning

Cont Cur Lim

Armature current value at the limit between

intermittent and continuous current in % related to

the nominal motor current (1.01)

0 100 50 %

3.12

auto-

tuning

Arm Inductance

Armature circuit inductance in millihenries.

0.00 655.35 0.00 mH x

3.13

auto-

tuning

Arm Resistance

Armature circuit resistance in milliohms.

0 65535 0 mOhm x

Long Parameter Menu

3.14 Cur Contr Mode

0 = Macro depend The operating mode is defined

by macro, see macro descript.

1 = Speed Contr Speed control

2 = Torque Contr Torque control

3 = Cur Contr Current control

4 = Speed+Torque Speed + torque, both

reference values are added

5 = Lim SP Ctr Speed control with external

torque limitation. That speed

reference via AI1 can be

limited externally via AI2 in its

torque. The torque limitation is

sign-independent.

6 = Lim Trq Ctr Torque control with speed

limitation (window control

mode) for master-slave

applications. Master and slave

receive the same speed

reference. The slave has its

own speed feedback (tacho-

generator / encoder), but is

working in the current or

torque control mode. If the

speed deviation (reference /

actual value) > ±50 rpm, there

will be an automatic

changeover to speed control

until the deviation is corrected.

Then this mode will be

resumed.

0 6 0 Text x

(1) no changes possible if the drive is in ON-status

Loading...

Loading...