33

System Description

B

B

Installation

Resistor Plate Verifi cation of RTCA SP Instrument

Lift the lock handle of the RTCA SP Station, so that the two bearings of the clamp plate

fi t into the grooves of the lock handle, then push lock handle downward to horizontal

position. The clamp plate will lock the RTCA Resistor Plate 96 at the horizontal position.

A green LED will light up on the front of the RTCA SP Station to indicate that a device

is engaged.

Make sure that all RTCA Contact Pins 96 and the contact pads of the RTCA Resistor

Plate 96 are clean and free from any dust or dirt particles. If not, use the RTCA Cleaning

Kit to remove any dust.

When inserting the RTCA Resistor Plate 96 into the slot of the Station, make sure

that the Resistor Plate is FULLY inside the pocket and is aligned properly with the

edges of the pocket. It should be fl at and without any tilt.

The Power LED (green) on the front panel of the RTCA SP Station remains on

while it is connected to the switched-on RTCA Analyzer.

Perform the test

Wait until the automatic scan fi nishes, then click Start to begin the test. While the test

is running, notice that the bottom of the program window reads “Test Col 1,2,3, ….12”,

and the status LED and communication LED on the RTCA Analyzer will fl ash during

the measurement.

Check the data

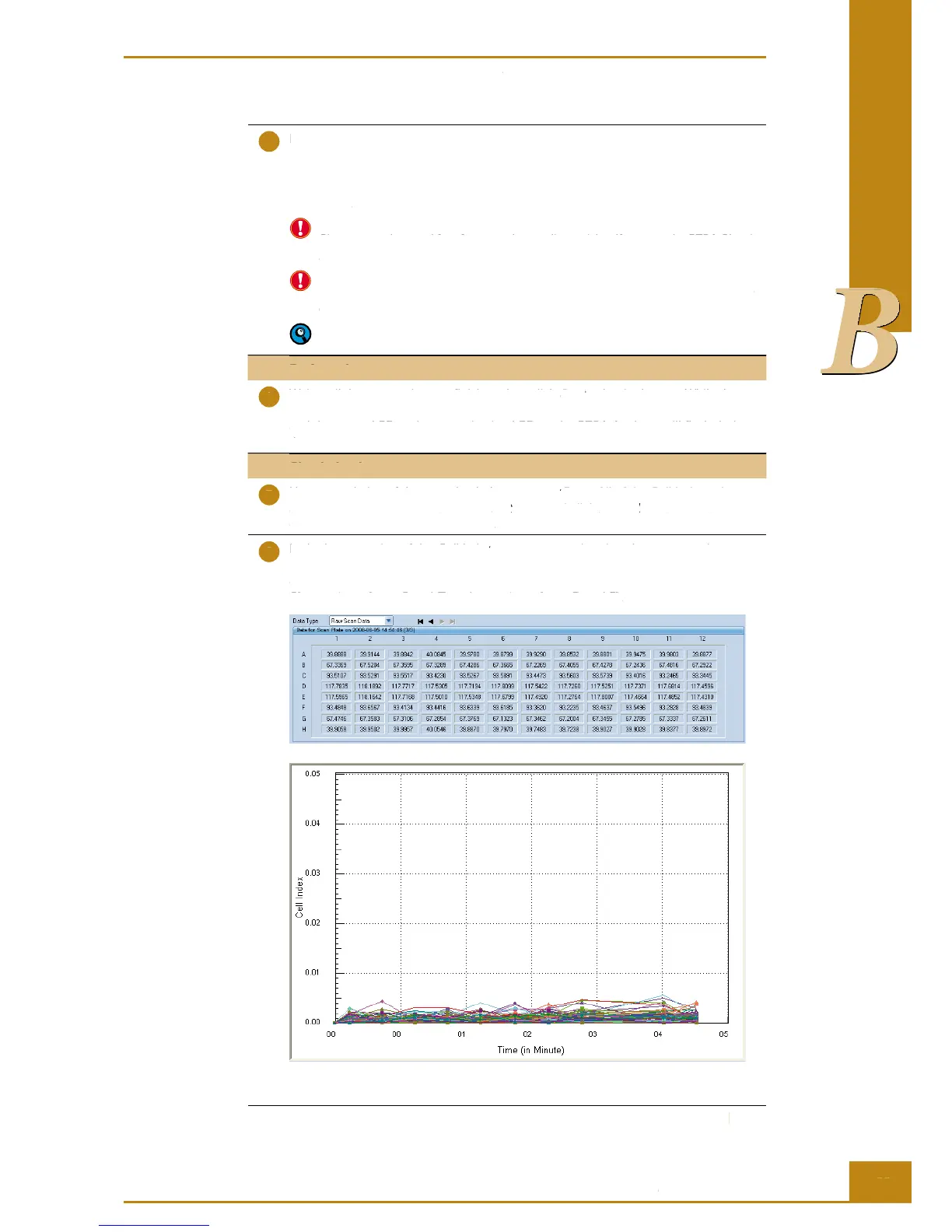

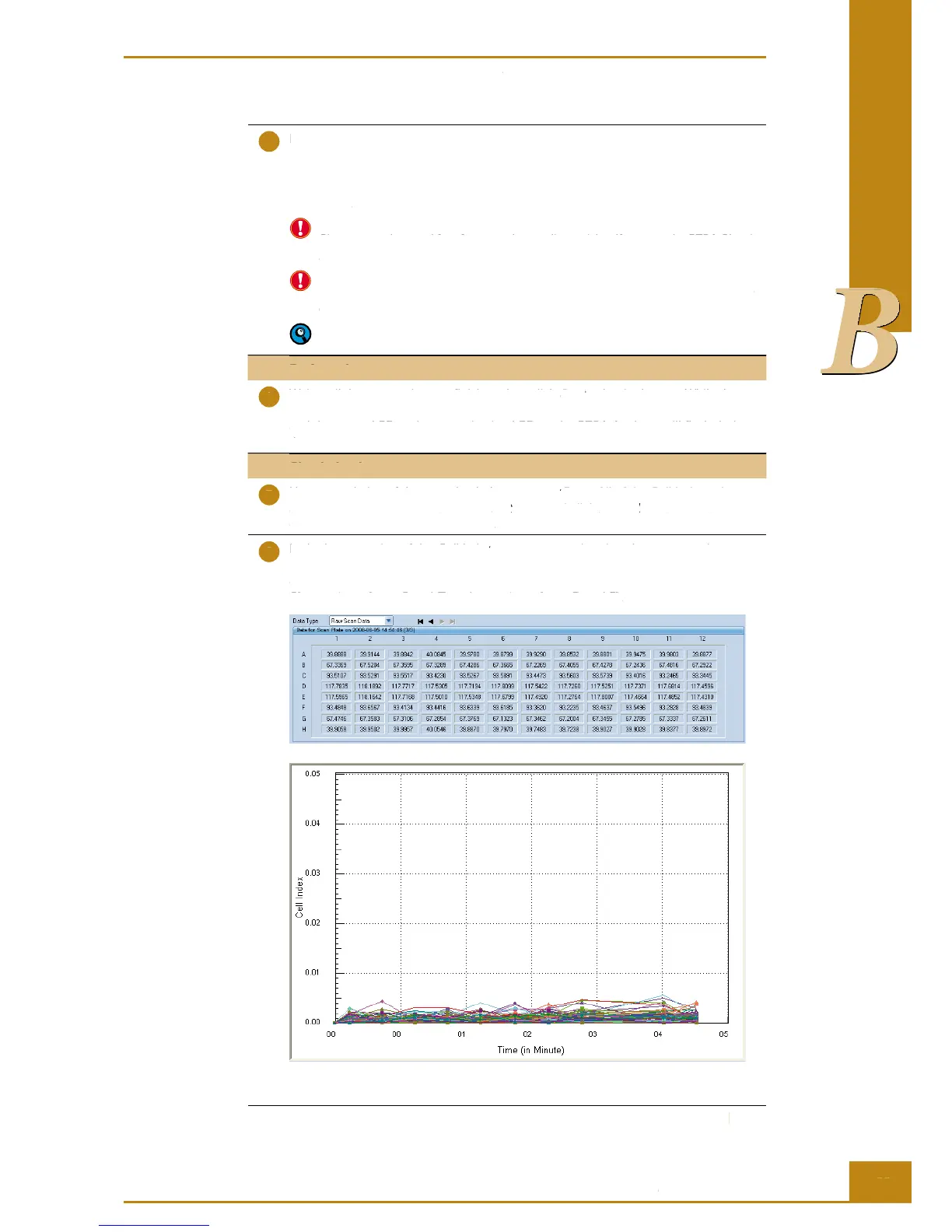

Upon completion of the test, check the Cell Index Page. All of the Cell Index values

should be less than 0.063. Go to the Plot page and click Add All. All CI values will be

displayed for the 96 wells (Figure 20).

In the lower portion of the Cell Index page, you can also view the raw scan data.

The data has 8 rows by 12 columns as shown in Figure 20. The raw scan data should

exhibit a repeated value pattern of 40.0 ± 2.0 (rows A and H), 67.5 ± 2.5 (rows B and

G), 93.6 ± 2.9 (rows C and F) and 117.6 ± 3.2 (rows D and E).

Figure 20: An example of resistor plate verifi cation calibration raw data and Cell Index curves.

Resistor Plate Verifi cation of RTCA SP Instrument

Lift the lock handle of the RTCA SP Station, so that the two bearings of the clamp plate

fi t into the grooves of the lock handle, then push lock handle downward to horizontal

position. The clamp plate will lock the RTCA Resistor Plate 96 at the horizontal position.

A green LED will light up on the front of the RTCA SP Station to indicate that a device

Make sure that all RTCA Contact Pins 96 and the contact pads of the RTCA Resistor

Plate 96 are clean and free from any dust or dirt particles. If not, use the RTCA Cleaning

When inserting the RTCA Resistor Plate 96 into the slot of the Station, make sure

that the Resistor Plate is FULLY inside the pocket and is aligned properly with the

edges of the pocket. It should be fl at and without any tilt.

The Power LED (green) on the front panel of the RTCA SP Station remains on

while it is connected to the switched-on RTCA Analyzer.

Wait until the automatic scan fi nishes, then click

to begin the test. While the test

Start to begin the test. While the test Start

is running, notice that the bottom of the program window reads “Test Col 1,2,3, ….12”,

and the status LED and communication LED on the RTCA Analyzer will fl ash during

Upon completion of the test, check the

Page. All of the Cell Index values

Cell Index Page. All of the Cell Index values Cell Index

should be less than 0.063. Go to the

Add All. All CI values will be Add All

displayed for the 96 wells (Figure 20).

In the lower portion of the

page, you can also view the raw scan data.

Cell Index page, you can also view the raw scan data. Cell Index

The data has 8 rows by 12 columns as shown in Figure 20. The raw scan data should

exhibit a repeated value pattern of 40.0 ± 2.0 (rows A and H), 67.5 ± 2.5 (rows B and

G), 93.6 ± 2.9 (rows C and F) and 117.6 ± 3.2 (rows D and E).

Figure 20: An example of resistor plate verifi cation calibration raw data and Cell Index curves.

Loading...

Loading...