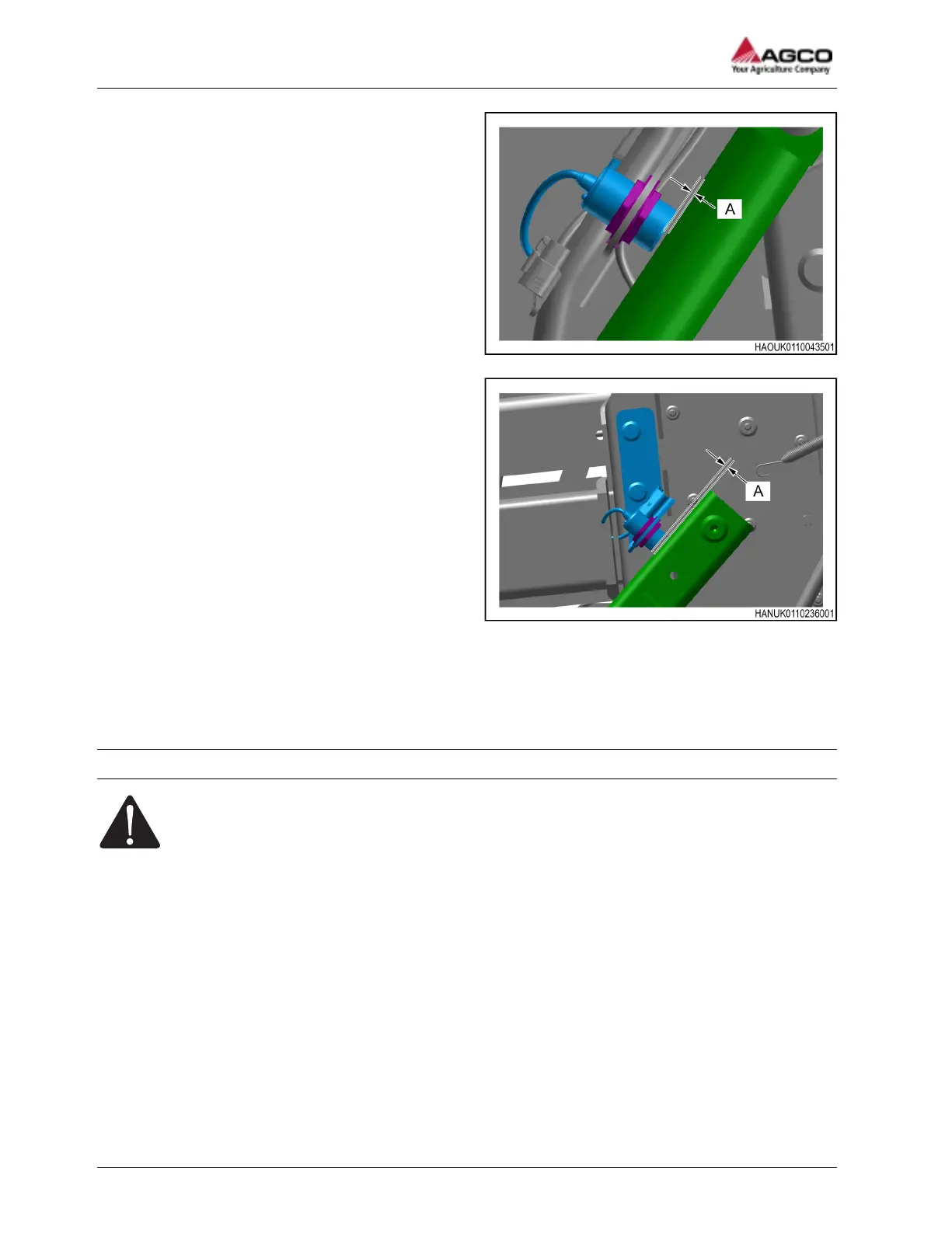

Fig. 7 1840 models

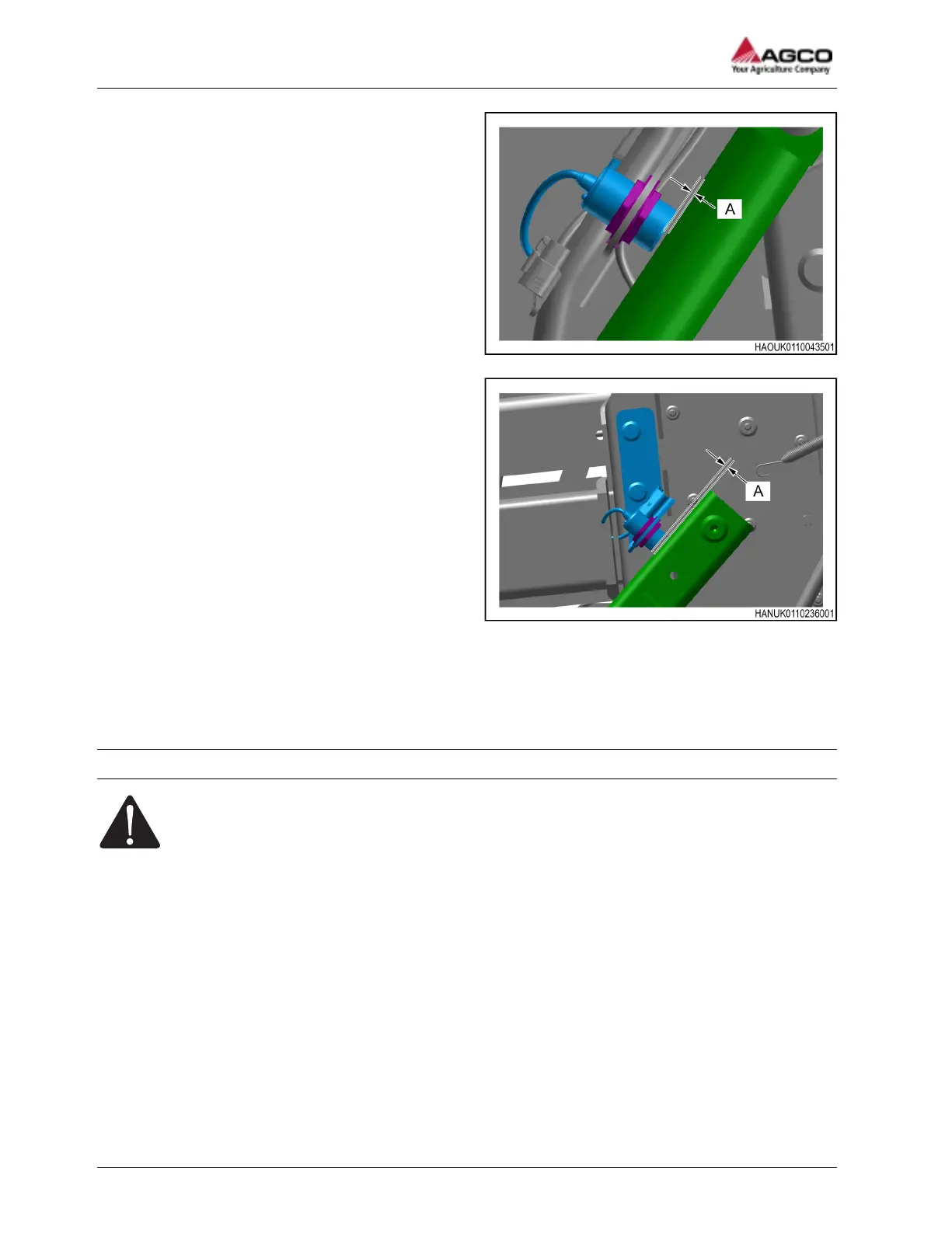

Fig. 8 1844 models

2. Loosen, but do not fully remove the 2 fasteners

on the needle carriage sensor.

3. Use the 2 fasteners to adjust the position of the

needle carriage sensor. The distance (A) must

be 3 mm (0.1 in) to 7 mm (0.3 in) when the

needle carriage is at the home position.

4. Tighten the 2 fasteners to the approved torque.

5. Do a check to make sure that the needle

carriage cannot touch the sensor or move out of

range when it is at the home position.

IMPORTANT: Make sure that the wiring harness

is connected to the needle carriage sensor.

a) Set the ignition switch to ON.

b) Slowly move the needle carriage and

examine the LED at the rear of the sensor.

Result of the procedure

The needle carriage sensor clearance is set correctly when:

• The LED is ON when the needle carriage is in the home position.

• The LED is OFF when the needle carriage is not in the home position.

4.1.3 Adjust the PTO speed sensor

DANGER: Dangerous area.

Risk of death or injury.

Before you go into the area between the machine and the implement:

Park the machine on a clean, hard and level area.

Put the parking brake to ON.

If an implement is on the machine, lower the implement to the ground.

Set the ignition to OFF.

Install the wheel chocks.

4 Maintenance

56

SimplEbale

Loading...

Loading...