Use and Maintenance Manual - X_RT Series Page 57

7.3 General maintenance

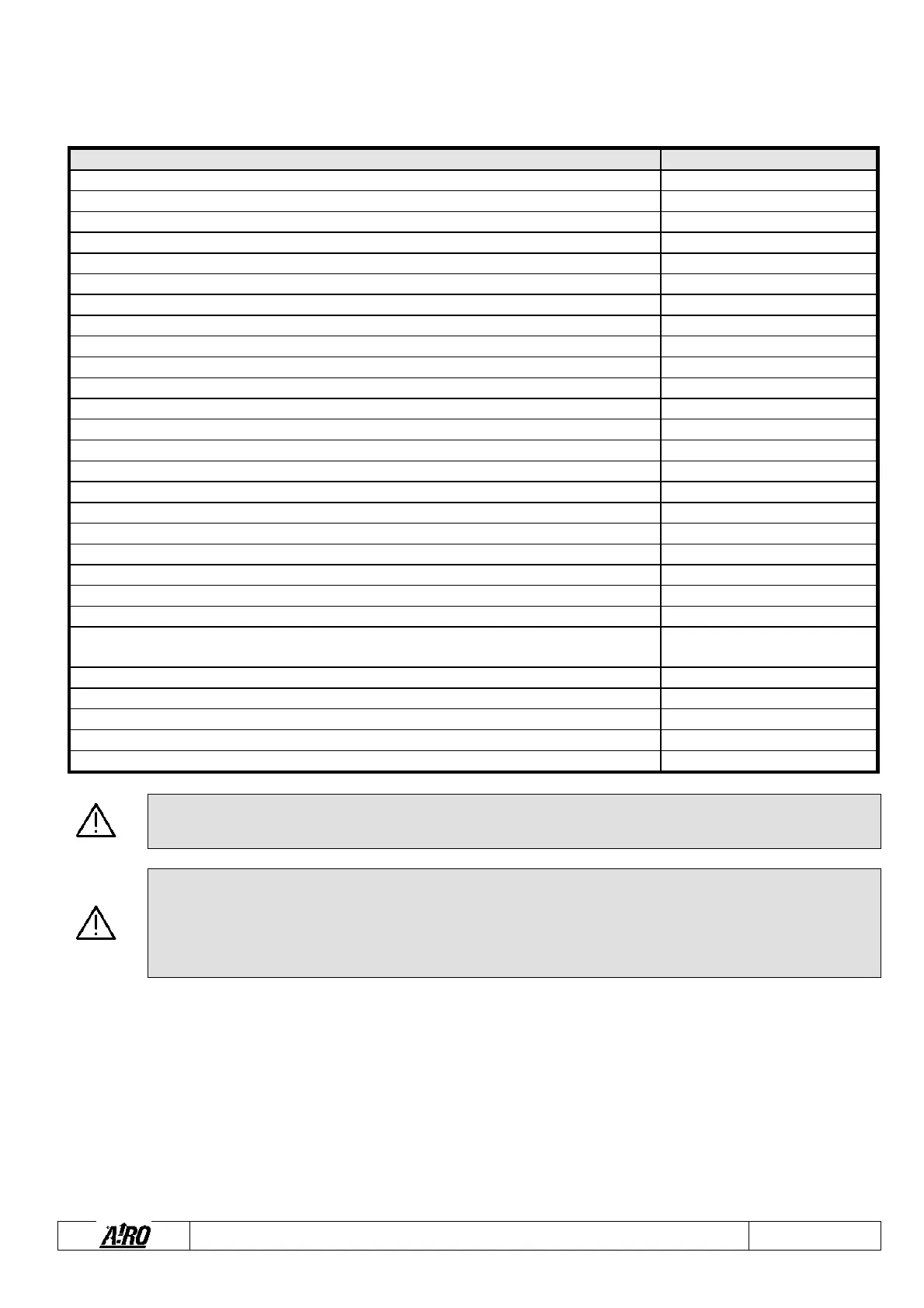

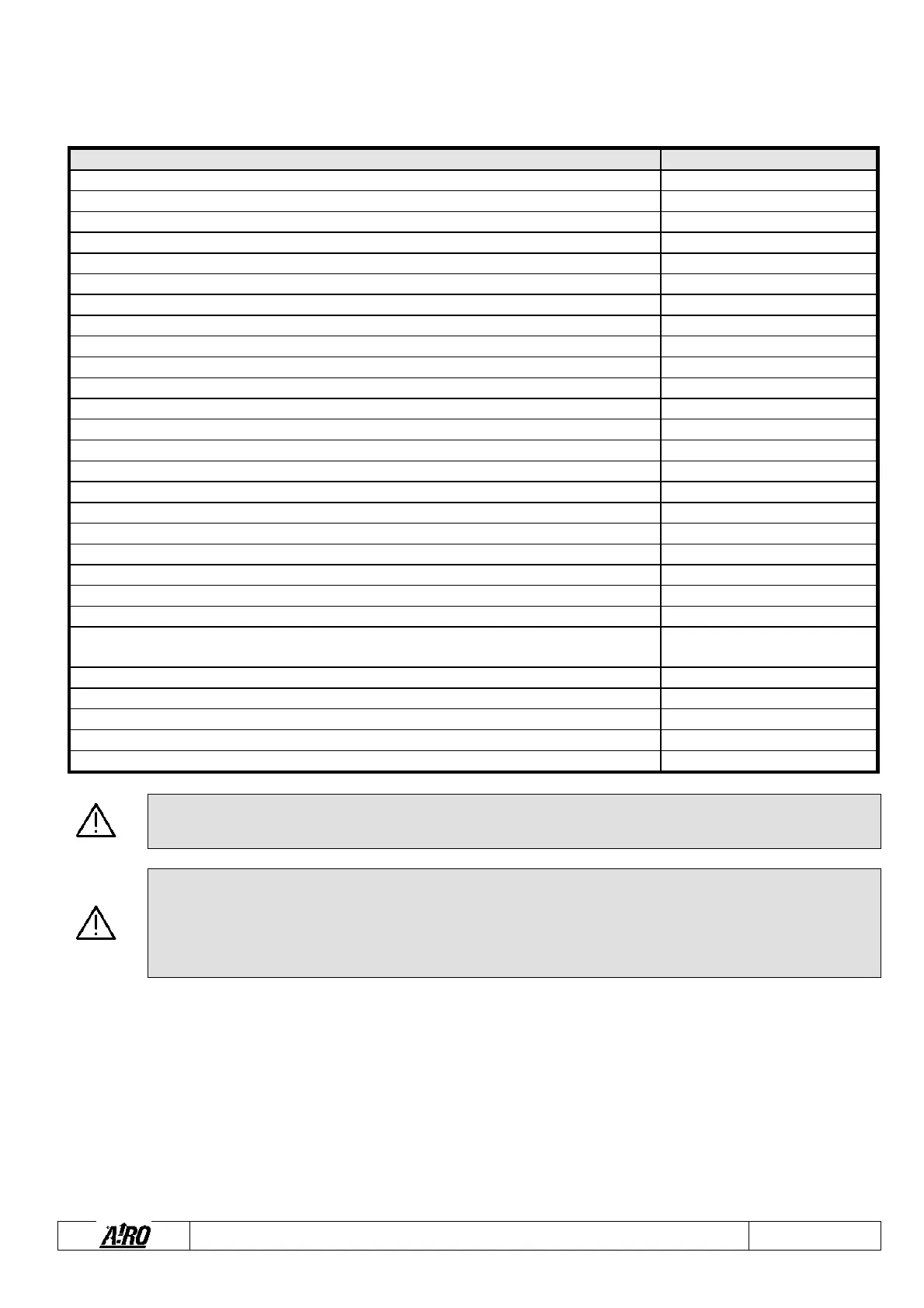

Below are listed the main maintenance jobs to be done and the relevant schedule (the machine features an hour meter).

Screw tightening (see paragraph "Various

After the first 10 working hours

Oil level check in hydraulic tank

After the first 10 working hours

Check of the battery state (charge and liquid level)

Coolant level check in the radiator (models “RTD”)

deformation of tubes and cables

Check of stickers and code plates

Articulated joints and sliding blocks greasing

Oil level check in hydraulic tank

Check of heat engine fixing on elastic supports

Emergency devices efficiency check

Electric connections check

Hydraulic connections check

Periodic operation check and structure visual check

Screw tightening (see paragraph "Various

Pressure relief valve calibration check

Lifting circuit pressure relief valve calibration check

Brake system operation check

Air purging from oscillating axe cylinders

Inclinometer operation check

Platform overload controller operation check and adjustment

M1 microswitch operation check

Operation check of Microswitch M1S (if available)

Microswitches ST1A÷ST4A and STP1÷STP4 (machines with levelling

Operation check of Microswitch M13 on oscillating axle

man switch check efficiency

Platform extraction clearance adjustment

Hydraulic filter replacement

Total oil change in hydraulic tank

DIESEL (D) AND ELECTRIC-DIESEL (ED) MODELS. As it is possible to install different types of Diesel

engines, refer to the instructions manual of the engine manufacturer for all maintenance operations.

IT IS NECESSARY

TO SEND THE MACHINE TO THE MANUFACTURER FOR A COMPLETE CHECK

WITHIN 10 YEARS OF WORK

Loading...

Loading...