Use and Maintenance Manual - X_RT Series Page 65

7.3.6 Air purging from oscillating axle locking cylinders

Once drive has been stopped, the axle locking cylinders are locked in

position thus increasing the machine stability.

Check that no air is present inside the oscillating axle cylinders every year. In

order to carry out this check it is necessary to raise the front wheels off

the ground (for machines equipped with levelling outriggers is sufficient

to lower the levelling outriggers) and verify that the axle remains in

position when stressed.

If you notice a movement of the axle, it is necessary to proceed to the

elimination of the air present in the cylinders in the following manner:

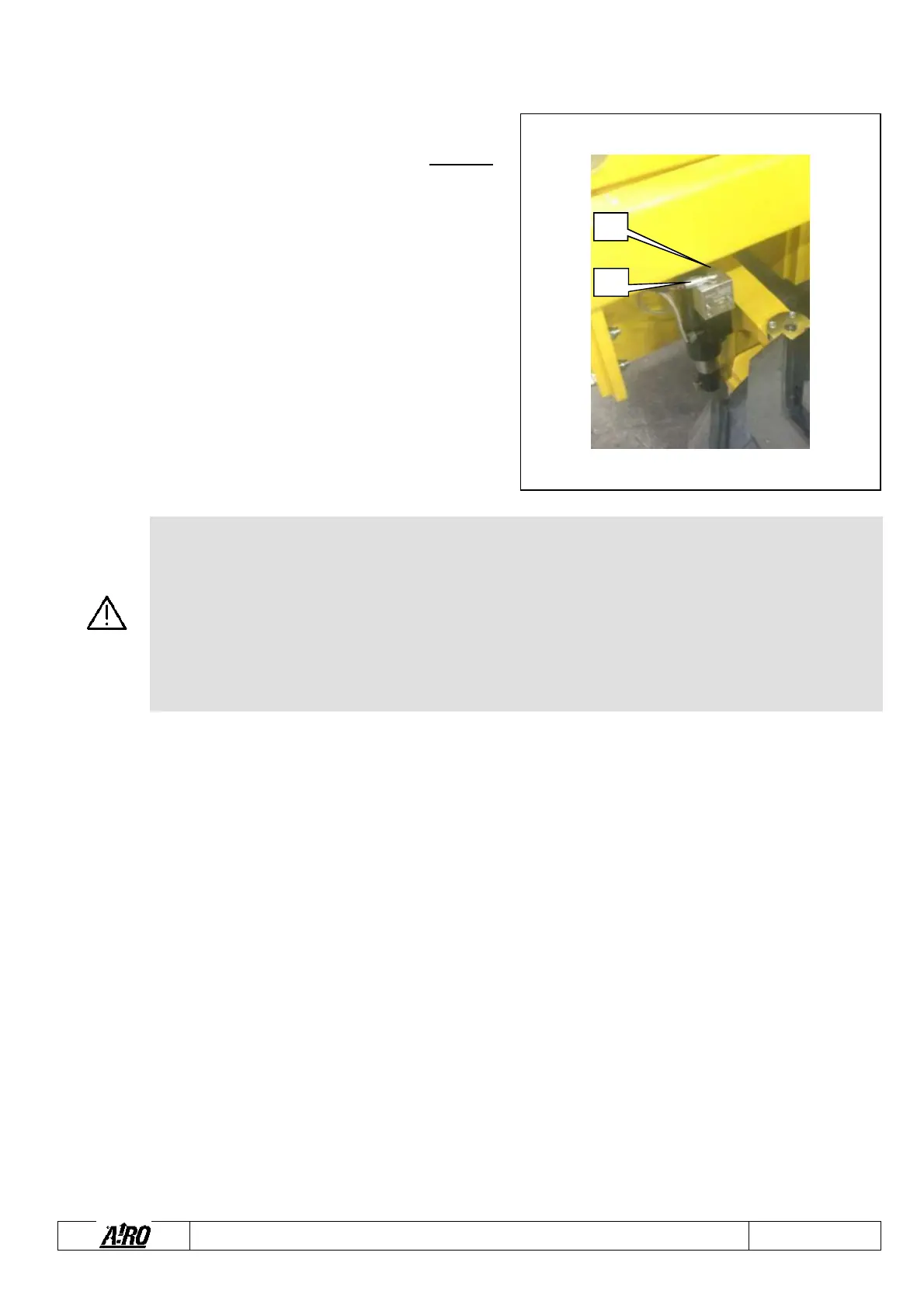

Unscrew cap (A) one of the two cylinders of the oscillating axle or, in

the absence of the cap, loosen the four captive screws valve (

B).

Carry out the drive operation by bringing the two oscillating

axle cylinders to end stop several times, until there is only oil

leaking out of the cap of the locking valve.

Once purging has been completed, screw cap (A) or tighten the

screws (B) and check the oil level in the tank.

THIS OPERATION OUGHT TO BE CARRIED OUT SIMULTANEOUSLY BY TWO OPERATORS: ONE IS TO

DRIVE THE MACHINE, THE OTHER IS TO CHECK THE OPERATION AND COLLECT THE LEAKING OIL.

THIS OPERATION SHOULD BE CARRIED OUT IN ROOMS THAT ALLOW THE OIL LEAKING FROM THE

CYLINDERS TO BE RECOVERED.

AS THIS OPERATION IS VERY IMPORTANT IT IS TO BE CARRIED OUT BY SPECIALIZED TECHNICIANS

Fig. 26

Loading...

Loading...