3. Hardware Description 40

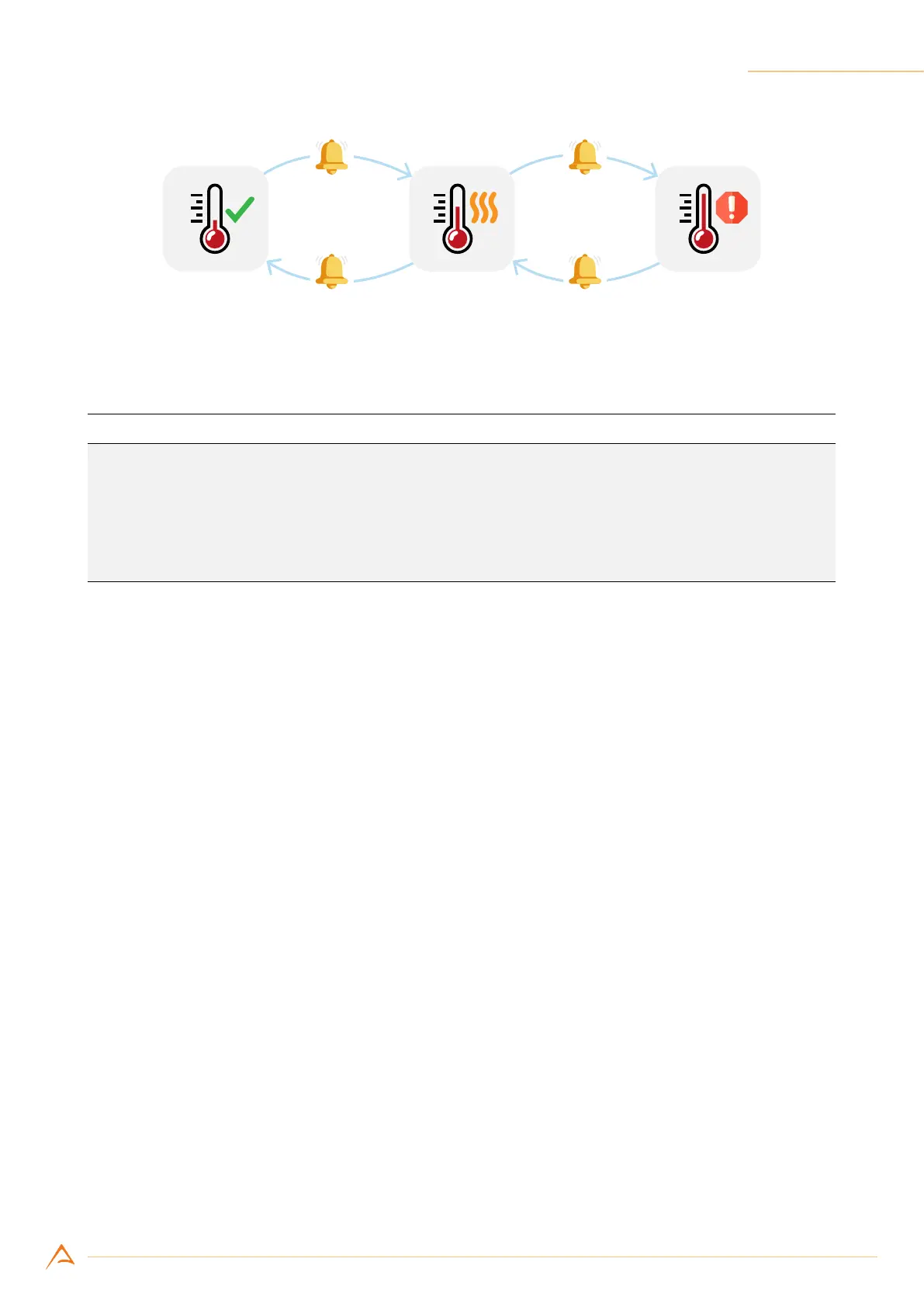

Figure 3.11: Temperature status transition

Example Code 3.2 | Temperature Change Event

device.OverTemperatureStatusChanged += delegate(object o, EventArgs a)

{

String msg = String.Format("Status: {0}", device.OverTemperatureStatus);

MessageBox.Show(msg);

};

device.OverTemperatureMonitorEnable = true;

3.6.7 EMI/ESD precautions: noise and electrostatic discharge

NECTA cameras are typically used in industrial environments, where many devices may generate elec-

tromagnetic interference and electrostatic discharge. Although NECTA cameras are designed to be ex-

tremely resistant to perturbations from the external environment, strong EMI and ESD transients may

cause unwanted behavior, such as false triggering and defects in an acquired image. Those issues can be

xed by adopting good practice in the harness and cable routing. To reduce EMI and ESD, it is therefore

essential to take some good general precautions when connecting the equipments:

• Install the camera as far as possible from high current loads such as motors or solenoids, especially

if powered by a switching power supply.

• Use cables with double shielding and keep them as short as possible. Keep the contact area always

clean and protected from dust.

• Separate power cables from signal cables. Avoid power cables running parallel to signal ones. This

recommendation applies both to camera cables and to any other cable used in the equipment.

• Pay attention to the ground connections: they must be implemented through a single reference

node, avoiding ground loops. Keeping your system powered from a single outlet will greatly re-

duce ground loop related problems.

• Install the camera far away from devices generating sparks or strong electromagnetic elds, such

as, for example, large transformers, welding machines and electric motors.

Loading...

Loading...